-- 51 --

bu09d12e2

7

MAINTENANCE

Note:

All warranty undertakings given by the supplier cease to apply if the customer

attempts to rectify any faults on the machine during the warranty period.

Only those persons who have appropriate electrical knowledge (authorised

personnel) may remove the safety plates to connect or carry out service,

maintenance or repair work on welding equipment.

Cleaning

Check regularly that the power source is free from dirt.

How often, and to what extent, cleaning should be carried out depends on the

welding process, arc time, disposition and the surrounding environment. It will

normally suffice to blow the power source clean using compressed air (reduced

pressure) once a year.

If the power source is very dirty, brushing and vacuuming are recommended.

S

Disconnect the welding power source from the mains current supply.

S

Remove the adapter from the socket. Lock the socket to prevent unauthorised

connection.

At fixed installations, the safety switch should be set to the off position. Lock

the switch.

S

Remove the power source’s safety plates for best access.

After cleaning, all safety plates must be mounted before you connect the power

source to the mains supply.

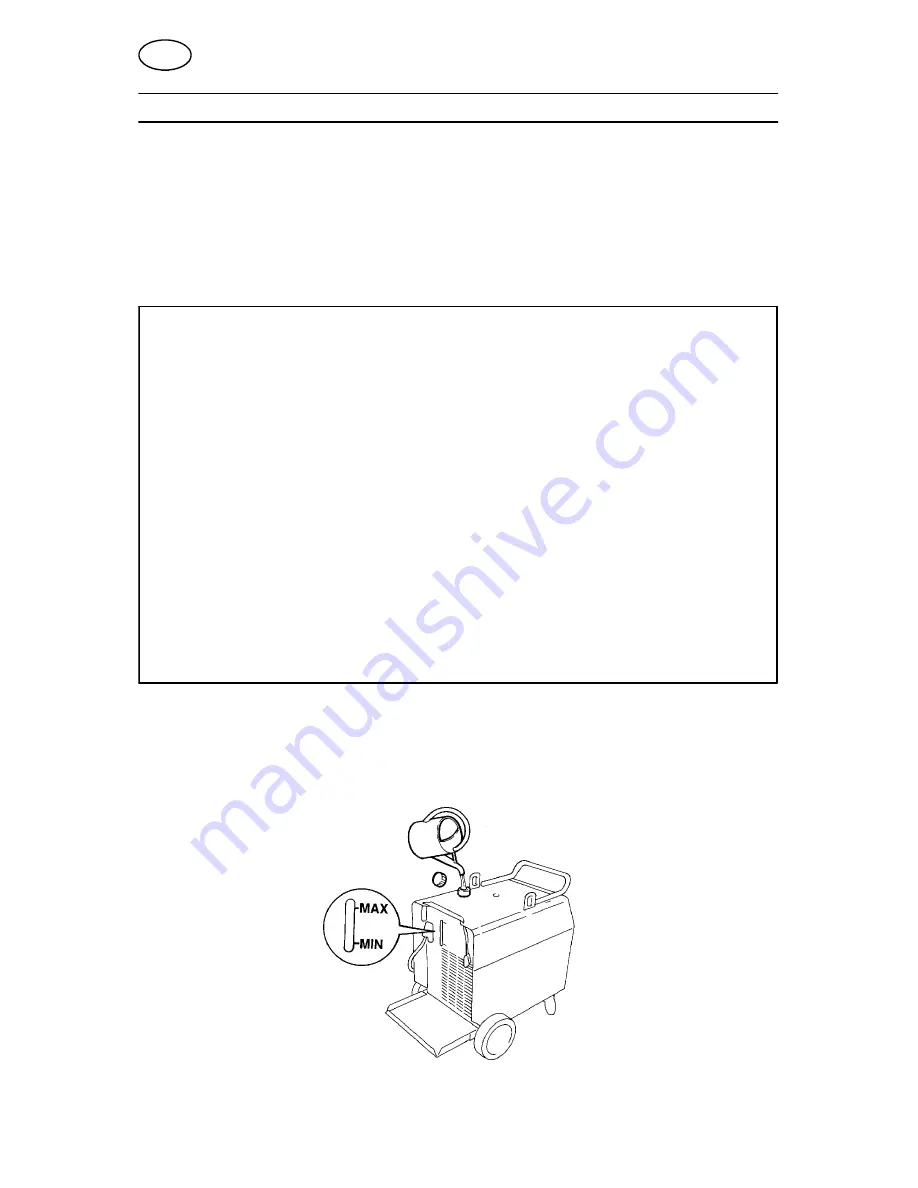

7.1

Topping up coolant

We recommend a 50/50 % mixture of water and ethylene glycol.

GB