7

918 series Powerig Hydraulic Units (HK786

)

Checking & Adjusting Pressures

PREPARATION FOR USING GAUGE T-124833CE

If necessary, prime and bleed the POWERIG

®

Hydraulic Unit.

See the

P

rEParation

for

u

SE

section of this manual.

NOTE:

Check each tool's pressure separately.

1. Turn OFF the POWERIG. Connect the male coupler of

gauge to PULL pressure female coupler of Powerig.

2. Connect female coupler of gauge to RETURN pressure

male coupler of Powerig.

3. Turn needle valve of T-124833CE all the way out.

4. Install auxiliary electric switch and control cord assembly

(P/N

113056

) in the control cord socket of the tool port

being checked, or use the trigger of the tool connected

to the ports being checked. Fluid will be directed out the

PULL pressure port when the switch is pressed. Connect

the Powerig to the primary power source and turn it ON.

CHECKING OUTPUT PRESSURES USING T-124833CE

1. Close the valve (turn handle clockwise). Press and hold

auxiliary trigger switch. Read the PULL pressure on right

gauge. Release trigger switch.

2. Open valve by a few counterclockwise handle turns.

3.

Press

and

Release

auxiliary trigger switch to set the unit’s

internal valve. Hydraulic fluid is directed out RETURN

pressure port.

4.

SLOWLY

close the valve. The pressure will rise, and then

sharply drop. Read the RETURN pressure on the left gauge

just before the pressure drops.

5. Open the valve. Turn OFF the Powerig.

6. Disconnect auxiliary trigger, then pressure setting gauge.

7. Refer to installation tool’s instruction manual for specific

PULL and RETURN pressures.

ADJUSTING OUTPUT PRESSURES

The POWERIG Hydraulic Unit should be prepared for

operation as described in

P

rEParation

for

u

SE

.

Use Gauge

T-124833CE to check pressures before and after adjusting

PULL and RETURN pressures.

ADJUSTING COMBINATION VALVE P/N 119740

The 918 and 918-5 POWERIG Hydraulic Units are equipped

with valves that can be set at specific PULL and RETURN

pressures (see the applicable instruction manual for your

tool). There is a socket-head screw to adjust PULL pressure

and a different one to adjust RETURN pressure. See Figure 7.

PULL PRESSURE ADJUSTMENT

Use 5/16” hex key for PULL pressure adjusting screw.

Turn adjusting screw clockwise to increase pressure.

b. Turn adjusting screw counterclockwise to decrease

pressure.

c. Check resulting PULL pressure setting with Gauge

T-124833CE.

RETURN PRESSURE ADJUSTMENT

Use 5/16” hex key for RETURN pressure adjusting screw.

a. Turn adjusting screw clockwise to increase pressure.

b. Turn adjusting screw counterclockwise to decrease

pressure.

c. Check resulting RETURN pressure setting with Gauge

T-124833CE.

WARNINGS:

Turn OFF the Powerig prior to connecting

or disconnecting tools. If it is necessary to

connect or disconnect a tool while the unit

is running, use the following procedure for

maximum safety.

Connect tool’s hydraulic hoses to unit before

connecting tools switch control cord to unit.

If a malfunctioning cord switch is connected

first, hydraulic unit may begin to cycle

unexpectedly. Unexpected cycling may lead

to serious injury. When connecting hoses,

switch MUST be connected last. Just as

important: When disconnecting hoses, switch

MUST be disconnected first.

Maximum PULL pressure is 8400 psi (648

bar). Refer to specific tool instruction manual

for PULL and RETURN pressures for Huck

installation equipment. Severe personal injury

may occur if excessive pressures cause

violent failure of equipment.

WARNING: Turn OFF the hydraulic unit.

Accidental cycling of the unit may cause

severe injury when disconnecting couplings.

Fluid may unexpectedly spray.

CAUTION: The following check must be

completed quickly. Sustained high pressure

will cause premature wear on the unit.

CAUTION: Whenever possible, set Powerig

pressures to the lowest recommended

pressure to minimize wear on the equipment.

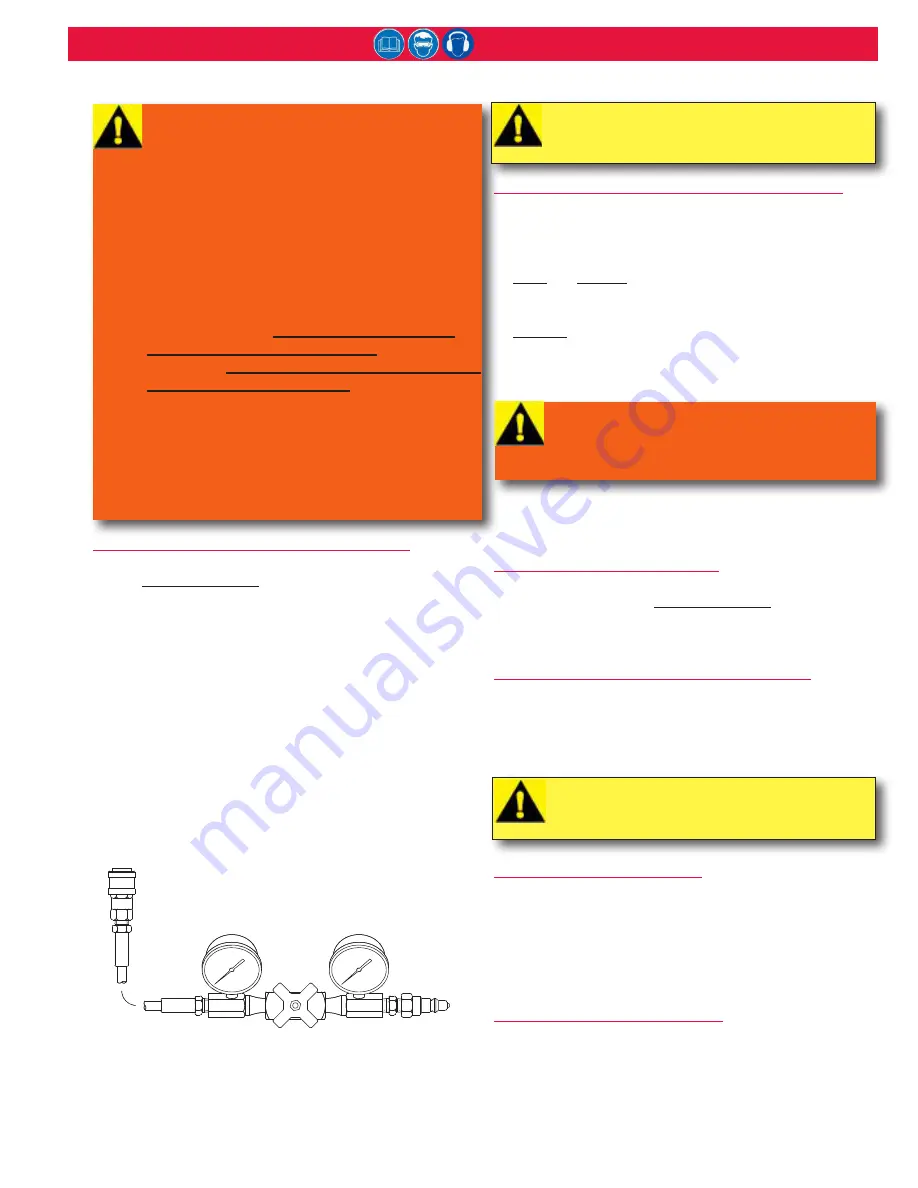

T-124833CE

Pressure Gauge

Summary of Contents for 918 Series

Page 2: ...2 918 series Powerig Hydraulic Units HK786 ...

Page 14: ...14 918 series Powerig Hydraulic Units HK786 918 918 5 Hydraulic Diagram Figure 5 ...

Page 15: ...15 918 series Powerig Hydraulic Units HK786 Typical Hose and Control Cord Hook up Figure 6 ...

Page 22: ...22 918 series Powerig Hydraulic Units HK786 Electrical Control Panel Wiring Figure 13 ...