7

2624 & 2630 series Hydraulic Installation Tools (HK1052)

See

Specifications

for fluid type. Dispose of fluid in

accordance with local environmental regulations. Recycle

steel, aluminum, and plastic parts in accordance with local

lawful and safe practices.

PREVENTIVE MAINTENANCE

The operating efficiency of your tool is directly related

to performance of the entire system. Therefore, a regular

schedule of “preventive” maintenance of the tool, nose

assembly, hydraulic hoses, trigger and control cord,

and Powerig

®

hydraulic power source will ensure your

tool’s proper operation and extend its life. Also see

Troubleshooting

, parts lists, and

Disassembly

and

Assembly

procedures in this manual.

POWERIG

®

HYDRAULIC POWER SOURCE

Maintenance instructions and repair procedures are in the

appropriate Powerig hydraulic power source Instruction

Manual.

SYSTEM INSPECTION

An effective maintenance program includes scheduled

inspections of the system to detect minor troubles that

can be quickly and easily

corrected. Huck recommends

that you:

Inspect the tool and nose for external damage

.

Verify that hoses, fittings, couplings, and electrical

connections are secure and free of leaks.

Inspect hydraulic hoses for signs of damage. Replace if

necessary.

Inspect the tool, hoses, and Powerig during operation to

detect abnormal heating, leaks, or vibration

.

TOOL

At regular intervals, depending on use, replace all O-rings

and Back-up rings in the tool. Spare Parts Kits should be

kept on hand. Inspect cylinder bore, piston, piston rod,

and unloading valve for scored surfaces, excessive wear,

and damage; replace as necessary

.

NOSE ASSEMBLY

Daily cleaning of the nose assembly is recommended.

This can usually he accomplished by dipping the nose

assembly in mineral spirits, or other suitable solvent, to

clean the jaws and wash away metal chips and dirt. If a

more thorough cleaning or maintenance is necessary,

disassemble the nose assembly. Use a sharp pointed

“pick” to remove embedded particles from the pull

grooves of the jaws

.

Maintenance

Stickers on the tool must be replaced when the cylinder is replaced, or if they become worn, damaged, or

unreadable. Refer to

Sticker Locations

in this manual for information on sticker locations and part numbers.

CAUTIONS:

Consult the Material Safety Data Sheet (MSDS)

before servicing tool.

Keep foreign matter out of the hydraulic

system. Keep separated parts away from dirty

work surfaces.

Dirt and debris in hydraulic fluid causes valve

failures in tool and Powerig® hydraulic power

source.

Check components drawings in this manual

for correct orientation of polyseals and dump

valve.

Do not use Teflon

® tape on pipe threads. Tape

can shred, resulting in malfunctions. Apply

Parker Threadmate, Loctite 567, or Slic-tite

stick to male pipe threads per manufacturer’s

instructions.

Always replace seals, wipers, and Back-up rings

when the tool is disassembled for any reason.

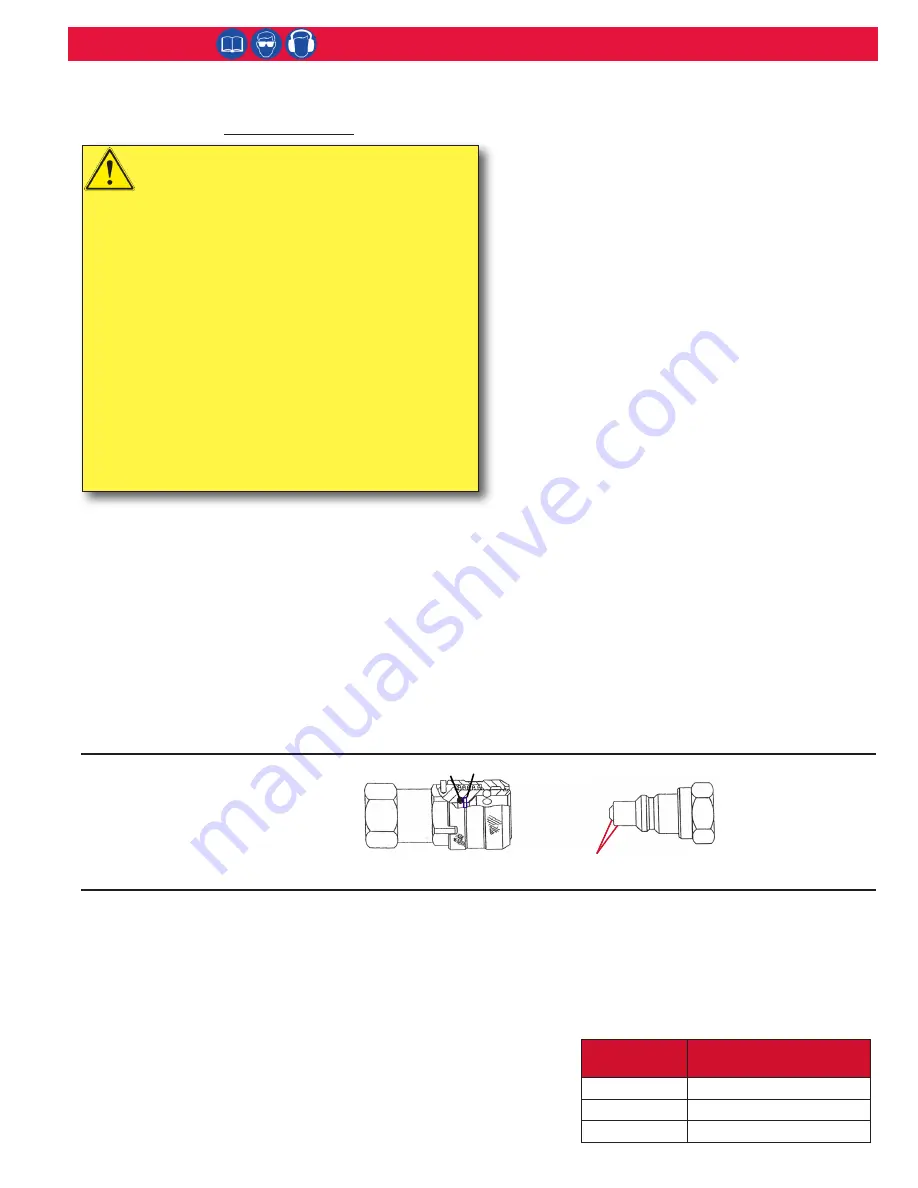

Hydraulic Couplings

504438 O-ring

501102 Back-up Ring

110439

Female

Connector

110438

Male

Connector

Use a fine India stone to remove any nicks or burrs from these

areas to prevent damage to O-ring of Female Connector.

Assembly of NPTF Threaded Components

AIR FITTINGS

1) Apply TEFLON® stick to male threads which do not have pre-applied sealant

per manufacturer’s recommendations. (Proceed to All Fittings step 2)

HYDRAULIC FITTINGS

1) Apply Threadmate

™

to male and female threads which do not have pre-applied

sealant per manufacturer’s recommendations. (Proceed to All Fittings step 2)

ALL FITTINGS:

2) Tighten to finger-tight condition.

3) Wrench tighten to 2-3 turns past finger-tight condition.

4) Final thread engagement can be checked (optional) by measuring the

dimension from the flange of male fitting to the end of the thread

before assembly and subtracting the distance under the flange after

assembly.

Thread Size Final thread engagement

at full make-up

1/8-27 NPTF

.235 inch

(.59 cm)

1/4-18 NPTF

.339 inch

(.86 cm)

3/8-18 NPTF

.351 inch

(.89 cm)