244BT Pneudraulic Installation Tool (HK1113)

7

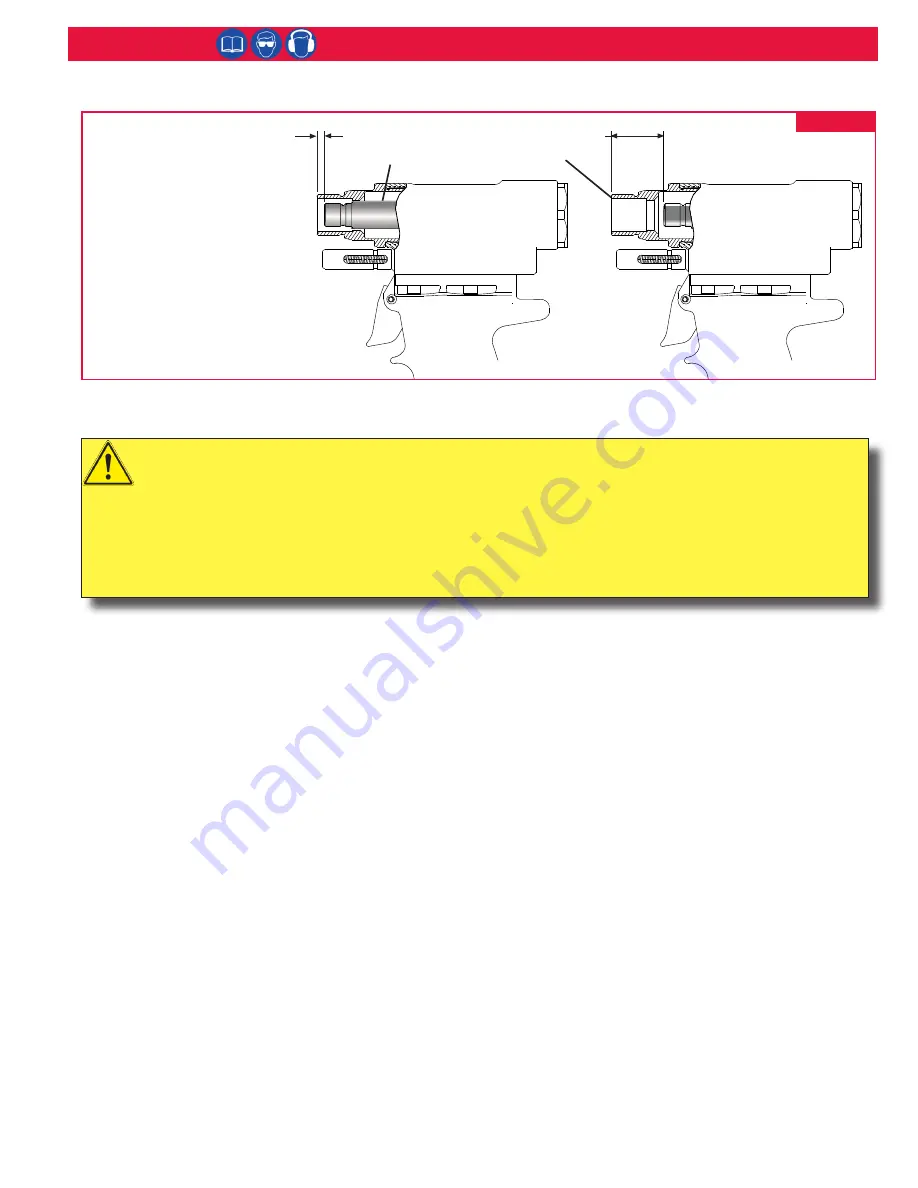

Measuring Tool Stroke

A

B

Nose

Adapter

Hydraulic

Piston

1. Measure distance “A”

from face of Hydraulic

Piston to face of Nose

Adapter. This distance

should approximately

equal .173 inches.

2. Cycle tool and hold

piston back by keeping

the trigger pressed.

Measure distance “B” as

above.

3. STROKE = B - A

(B minus A)

Maintenance

NOTES: See

S

pecificationS

for fluid type. Dispose

of fluid in accordance with local environmental

regulations. Recycle steel, aluminum, and plastic parts

in accordance with local lawful and safe practices.

GENERAL

1. The efficiency and life of any tool depends upon

proper maintenance. Regular inspection and correction

of minor problems will keep tool operating efficiently

and prevent downtime. The tool should be serviced

by personnel who are thoroughly familiar with how it

operates.

2. A clean, well lit area should be available for servicing

the tool. Special care must be taken to prevent

contamination of pneumatic and hydraulic systems.

3. Proper hand tools, both standard and special, must be

available.

4. All parts must be handled carefully and examined for

damage or wear. Always replace Seals, when tool is

disassembled for any reason. Components should be

disassembled and assembled in a straight line without

bending, cocking, or undue force. Disassembly and

assembly procedures outlined in this manual should

be followed.

5. Service Parts Kit 244BTKIT includes consumable

parts and should be available at all times. Other

components, as experience dictates, should also be

available.

DAILY

1. If a Filter-Regulator-Lubricator unit is not being used,

uncouple air disconnects and put a few drops of

Automatic Transmission Fluid or light oil into the air

inlet of the tool. If the tool is in continuous use, put a

few drops of oil in every two to three hours.

2. Bleed the air line to clear it of accumulated dirt or

water before connecting air hose to the tool.

3. Check all hoses and couplings for damage or air leaks,

tighten or replace if necessary.

4. Check the tool for damage or air/hydraulic leaks,

tighten or replace if necessary.

5. Check the nose assembly for tightness or damage,

tighten or replace if necessary.

6. Check oil level in tool reservoir, replenish if necessary.

WEEKLY

1. Disassemble and clean nose assemblies and

reassemble.

2. Check the tool and all connecting parts for damage or

oil/air leaks, tighten or replace if necessary.

CAUTIONS:

Consult MSDS before servicing tool.

Keep dirt and other material out of hydraulic system.

Separated parts most be kept away from dirty work surfaces.

Always replace seals, wipers, and back-up rings when tool is disassembled for any reason.

Do not use TEFLON® tape on pipe threads. Pipe threads may cause tape to shred resulting in tool

malfunction. (Threadmate™ is available from Huck in a 4oz. tube as part number 508517.)

Dirt/debris in hydraulic fluid causes Dump Valve failure in Tool and in Powerig Hydraulic Unit’s valves.

Figure 1