6

202 series Pneudraulic Installation Tools

(HK938)

The

202

series of tools ship with a plug in the air inlet

connector. The connector has 1/4-18 female pipe

threads to accept the air hose fitting. Huck recommends

quick-disconnect fittings and a 1/4” inside-diameter air

hose. The air supply should be equipped with a filter-

regulator-lubricator unit, and access to a 90 psi (

6.2 bar

)

air supply capable of 8.5 scfm (

241 l/m

).

NOTE

:

Air quick-disconnect fittings and air hoses

are not available from Huck International, Inc.

1. Remove the shipping plug from air inlet connector

and add a few drops of an approved hydraulic fluid

.

2. Screw the quick-disconnect fitting into the air inlet

connector.

3. Set the air pressure on the regulator to

90–100

psi, and connect the air hose to the tool

. Press and

release the trigger a few times to cycle the tool.

4. Disconnect the air hose from the tool, and remove

the retaining nut. Select the proper nose assembly

for the fastener being installed.

5. Screw the collet assembly (including the lock collar

and shim if applicable) onto the spindle and tighten

with a wrench.

6. Slide the anvil over the collet assembly and into the

counterbore. Slide the retaining nut over the anvil,

and screw the nut onto the head.

7. Connect the air hose to the tool and install fasteners

in a test plate of proper thickness with proper size

holes. Inspect the fasteners.

If fasteners do not pass inspection, see

T

roubleshooTing

to investigate possible causes.

NOTE

:

On older nose assemblies with lock collars, use

Loctite

®

243™ on collet threads, because the 202 pull

piston does not have staking holes. Refer to the nose

assembly drawings that shipped with nose assemblies.

Preparation for Use

CAUTION: Do not use TEFLON

®

tape on

pipe threads. Tape can shred, resulting in

malfunctions. Threadmate

®

is available in a

4oz. tube from Huck (P/N 508517).

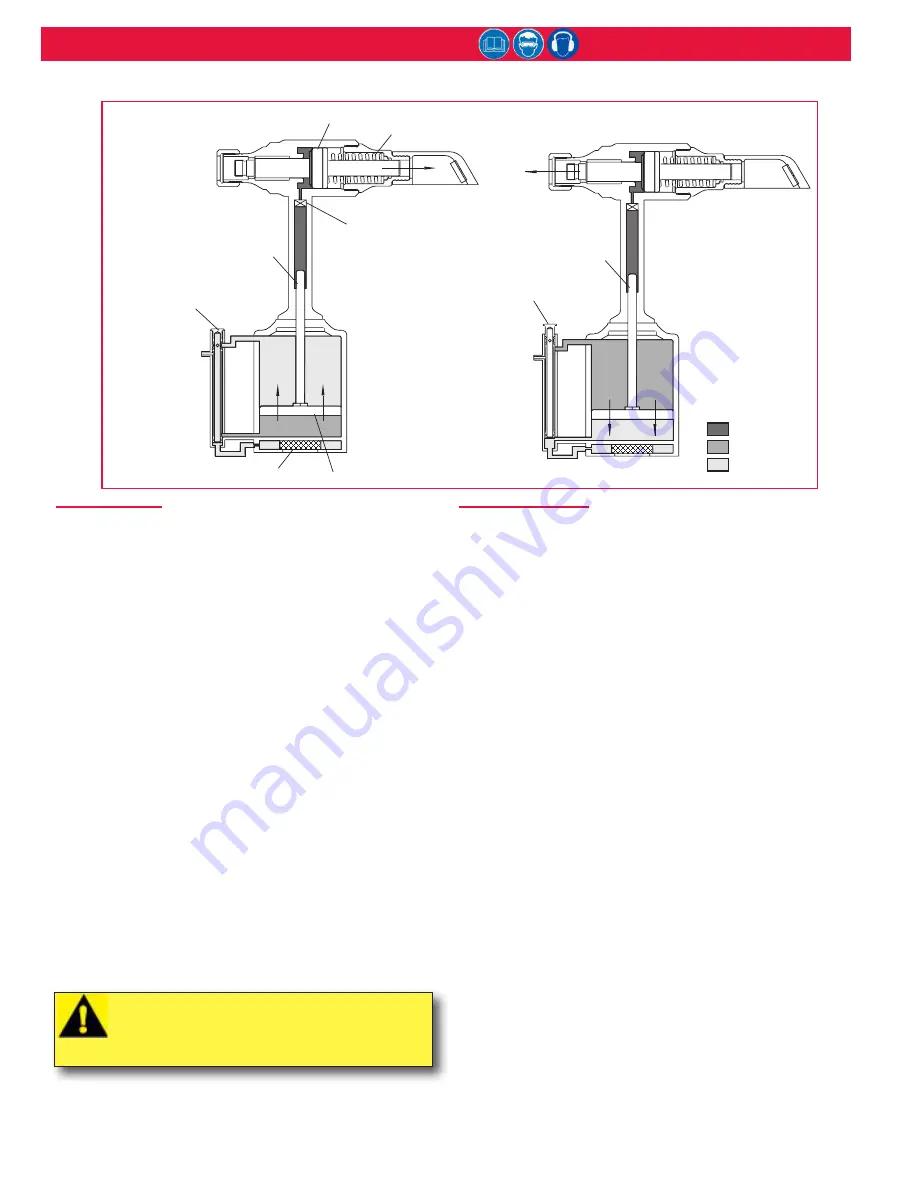

PULL STROKE

When the trigger is pressed, the throttle valve moves

down to the PULL position, and pressurized air is

directed to the bottom of the air piston, causing it to

move upward (as shown above). The air above the air

piston is exhausted and directed through the center of

the throttle valve and out the bottom of the tool.

As the hydraulic piston rod moves upward, a column

of fluid is forced into head, which moves the pull piston

rearward. The attached nose assembly moves with the

pull piston to start fastener installation.

RETURN STROKE

When fastener installation is completed, the trigger is

released. Air pressure, with the assistance of a spring,

sends the throttle valve to the up (RETURN) position.

Pressurized air is re-directed to the top of the air piston

(see above), causing the air piston and hydraulic rod to

move downward.

The air from below the piston is exhausted through the

bottom of the tool, and springs force the pull piston to

return to its home position. The damper valve impedes

oil flow at pinbreak to prevent “tool kick.”

Principles of Operation

TEFLON

is a registered trademark of E. I. du Pont de Nemours and

Company.

Threadmate

is a registered trademark of Parker Intangibles, LLC.

Loctite

is a registered trademark of Henkel Corporation, U.S.A.