16

Installation guide page 1

Attention!

The already assembled membranes can be stored for approx. 5 months in the sealed

pressure tube, preferably cool, but preferably not above 20 ° ambient temperature.

However, we recommend installing and using the Watermaker as soon as possible.

Warning!

Hose connections below the water line should secured with 2 hose clamps.

All hose clamps must check time to time and tighten if need.

During assembly of the hose nozzles and fittings, few windings of Teflon-tape have to be

wrapped around the screw thread against screw direction as tightly as possible. The

fittings may not be screwed too tightly in the filters or valves.

Thru-hull fitting, Strainer and feed pump

Install a thru-hull fitting and sea-cock, preferably deep under water line. The best place is about mid-ships behind

the keel. Install strainer and feed pump close as possibly to the sea-cock.

Attention!

To avoid mechanical stress, do not mount the strainer directly to the sea-

cock. The thru-hull fitting, coarse filter and the feed pump have to be located

in an area that will always be under the waterline when the boat is used under

normal running conditions.

In order to avoid accumulation of air,

if possible, install hoses

moved upward from the thru-hull fitting to the filters and up to the high-pressure pump.

From the sea-cock outlet to the feed pump inlet, the installation must be horizontal or

better rising. In order to stay as deep as possible below the waterline, a 90 ° hose nozzle

at the sea-cock outlet can be helpful.

Attention!

Avoid connecting to an existing inlet e.g. Main machine air conditioning. Common

operation is usually not possible because the existing hose cross-sections prevents

sufficient inflow.

Attention!

The feed pump is not self-priming and must be flooded before switching on, otherwise

the bearing will be destroyed by dryness.

To allow air to escape, switch the pump on and off several times and, if necessary, open

the vent valves on the prefilter.

If necessary, remove the high-pressure hose to the membrane at the high-pressure pump

and close it again after the water has escaped while the feed pump is running. This also

ensures that the HP pump is filled with water.

The system can also be vented by flushing with fresh water.

If necessary, refer to the further notes under Troubleshooting.

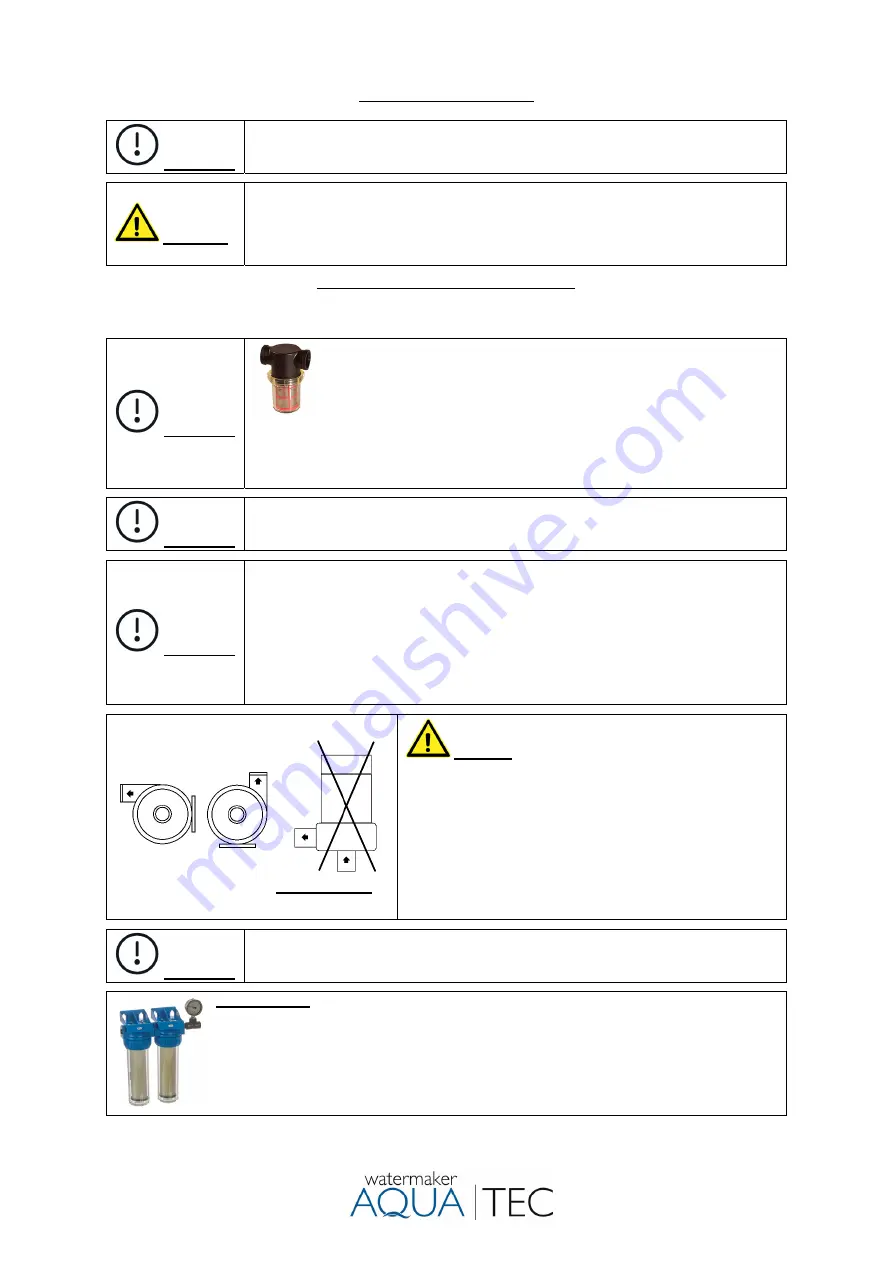

Mounting position of the feed pump

OK OK

not permitted

Warning!

Do not connect the feed pump directly to a

filter housing, tap or similar (risk of breakage).

Only connect to other components with the enclosed hose

nozzles and hose. The following installation position must be

observed in order to make it difficult to set deposits and to

allow the escape of air.

Permissible system pressure fresh water flush:

Feed pump

MD 40,

115 or 230V, 2 bar (29 psi).

Feed pump

B-C20/A,

400 or 440V, 3.5 bar (50 psi)

(If necessary, install a pressure reducer.)

Attention!

Depending on the used thru-hull fitting, hull shape and speed, the inflow of seawater can

be hampered or even be impossible. Damages to the plant due to insufficient or missing

seawater inflow will not be covered by the warranty or guarantee.

Filter housing:

For a good sealing of the filter housing, please lubricate the O-rings in the filter bowls with

acid-free silicone grease.

Mount the filter housing at an easily accessible place. Connect the filter inlet with the outlet of

the feed pump and the filter outlet via PVC hose with the high-pressure pump. Secure all hose

connections with stainless steel hose clamps. Install all hose connections in a way that air

accumulations are avoided.

Summary of Contents for Watermaker AC 110

Page 13: ...13 Memos...

Page 15: ...15 Flow diagram AC 190 Flow diagram AC 240...

Page 35: ...35 Specification...

Page 38: ...38...