1HP & 2HP Fusion Series Owner’s Manual

Page 3

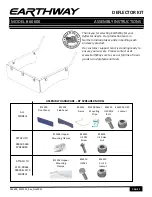

NOZZLE BUILD TIPS AND W ARNINGS

•

All nozzle builds are in Appendix A

•

When building the Nozzle, it is best to work from inside out to provide room to work.

•

Center Nozzle will always be installed last.

Im portant Notice on the FUSION Series M ulti-N ozzle

Com ponents Carry No W arranty W hen Assem bled Im properly

This Innovative Multi-Nozzle Casting was designed to offer you the flexibility to switch spray

patterns as desired. The screws provided can be inserted multiple times in various locations without

damaging the holes. Extra parts have been included as spares in the event they are needed.

Nozzles should be assembled using even and gradual tightening. The screws should be tightened

snuggly using hand tools only and opposing sides should be tightened evenly. Over-torquing the

screws may result in damages not covered under the manufacturer’s warranty. Power tools are

not allowed.

The assembled nozzle should be handled by the base. Transporting the assembly using the

individual tube assemblies or components may result in damages not covered under warranty.

Nozzle components are warranted for 30 days and solely replaced due to manufacturing defects.

All other damages caused by improper handling and/or assembly will require replacement parts

purchased through your distributor.

There is a separate instruction sheet to use when installing the Optional Twister Module. If you

experience difficulty implementing the build for your preferred spray pattern based upon the

instructions provided, please contact Aquatic Technologies for assistance.

Unlike the pump itself, the Twister Module carries a one (1) year manufacturer’s

warrantyagainst defects.