2M-Z2381

1:

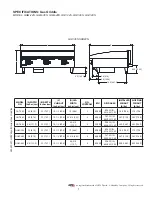

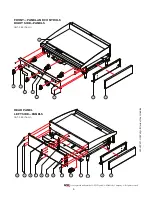

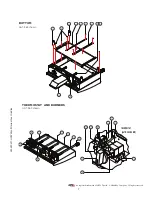

APW Wyott Series Gas Griddles

2

GENERAL INSTALLATION DATA

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by the

general public in food service locations.

The APW Wyott model griddles are equipped for use with the types of gas specified on the nameplate.

All units are shipped from the factory for use with natural gas. The unit can easily be converted

for use on propane gas: See propane gas.

-IMPORTANT-

The installation of the Appliance should conform to the NATIONAL FUEL

GAS CODE "ANSI Z223.1 - LATEST EDITION" AND ALL LOCAL GAS

COMPANY RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE

CURRENT CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE OR

CAN/CGA-B149.2 PROPANE INSTALLATION CODE AND LOCAL CODES

WHERE APPLICABLE.

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing the equipment.

For your safety, do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance. Keep the appliance area clear and free from

combustibles.

This appliance, its pressure regulator and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of that system at test pressures

in excess of 1/2 PSIG (3.45KPA).

This appliance and its pressure regulator must be isolated from the gas supply piping system by closing

its individual manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 PSIG (3.45KPA). For your protection, we recommend a qualified

installing agency install this appliance. They should be familiar with gas installations and your local

gas requirements. In any case, your gas company should be called to approve the final installation.

In addition, there should be posted, in a prominent location, detailed instructions to be followed in the

event the operator smells gas. Obtain the instructions from the local gas supplier.

For your safety, if you smell gas:

1. Do not touch electrical switches.

2. Extinguish any open flame.

3. Immediately call your gas company.

KEEP THE APPLIANCE AREA FREE AND CLEAR FROM COMBUSTIBLES.

CLEARANCE

For use on non-combustible countertops only.

Combustible and non-combustible material must be at least 48" (120cm) from the top of the

appliance and 6" (150mm) from the sides and back. Adequate clearance should also be

provided for proper operation and servicing.

AIR SUPPLY

Make certain not to obstruct the flow of combustion and ventilation air. Provisions for adequate air

supply must be furnished. The legs supplied with the unit must be installed. Make certain that air intake

openings in the bottom of the appliance are not obstructed. They are essential for proper combustion

and operation of the appliance.

CAUTION

CAUTION

CAUTION

CAUTION

Summary of Contents for GGM-24S

Page 15: ...PAGE INTENTIONALLY LEFT BLANK...