ENGINE

3 - 62

ENGINES C361M / C364M

3.11.9.

RECOMPOSITION OF THE CRANKCASE AND

DRIVE SHAFT

•

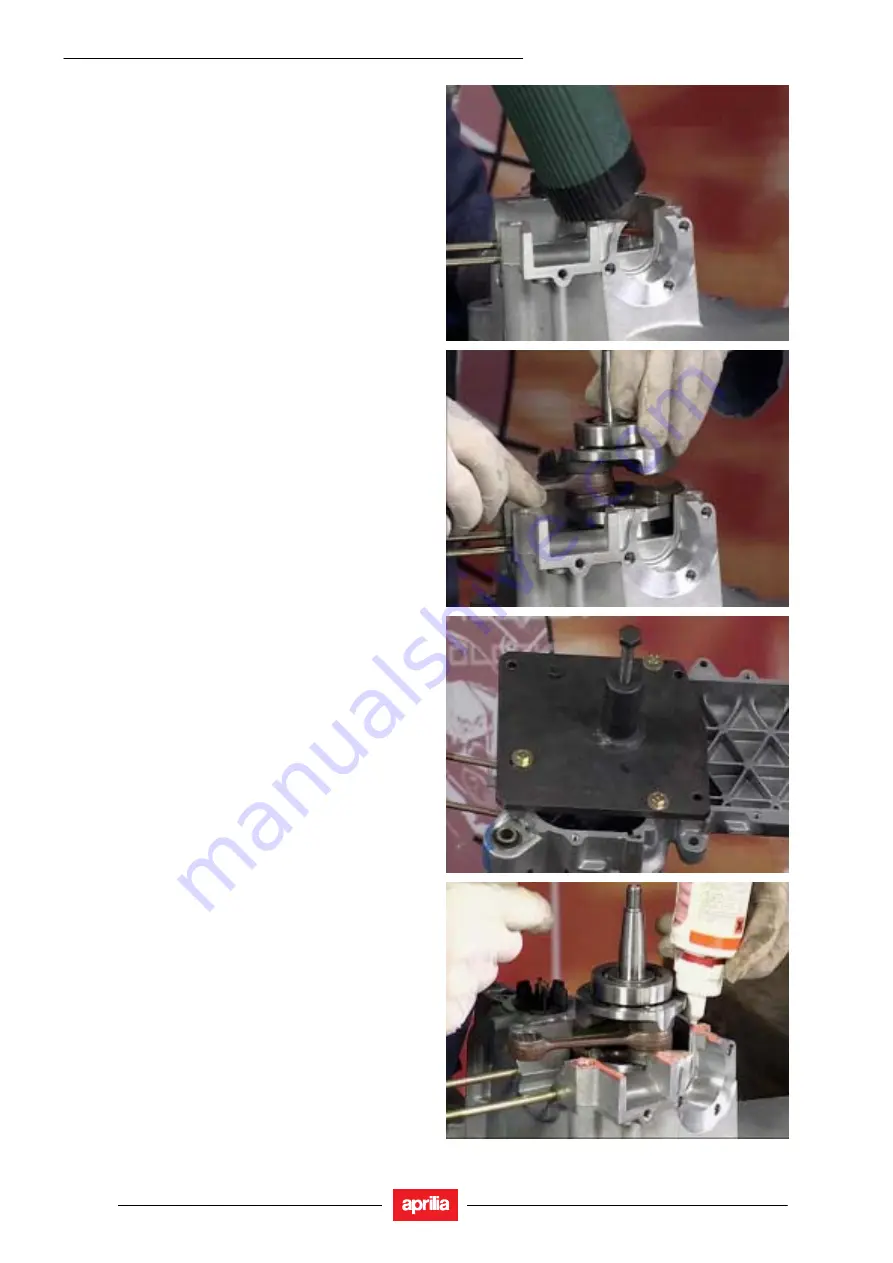

Position the half-case on two suitable supports. Use a

heat gun to heat the seat of the bearing to about

120°C.

•

Insert the drive shaft until the bearing reaches its end

of travel stops. Make sure the con rod is aligned with

the axis of the cylinder.

•

Reinstall the specific crankcase separation plate. Do

not install the drive shaft guard.

•

Slacken the central thrust bolt during the reassembly

operations. Bring the attachment bolts ot the end of

their travel and then slacken them to the same angle.

•

When the temperature is steady, preload the thrust bolt

of the tool just enough to cancel the play of the balls of

the bearing.

•

Degrease the surface with an appropriate solvent and

apply a thin layer of Loctite.

Summary of Contents for C216M

Page 1: ...www serviceaprilia com workshopmanual Engines C361M C364M C216M 1234 4 00 2004 10 8140822 UK ...

Page 8: ...GENERAL INFORMATION 1 1 ENGINES C361M C364M GENERAL INFORMATION 1 ...

Page 17: ...TECHNICAL INFORMATION 2 1 ENGINES C361M C364M TECHNICAL INFORMATION 2 ...

Page 23: ...ENGINE 3 1 ENGINES C361M C364M ENGINE 3 ...

Page 81: ...ENGINE 3 59 ENGINES C361M C364M Lubricate the bearings and big end ...

Page 93: ...ENGINE 3 71 ENGINE C361M Remove the fins support ...

Page 101: ...UPDATES ENGINE C364M 4 1 ENGINES C364M UPDATES ENGINE C364M 4 ...

Page 118: ...UPDATES ENGINE C364M 4 18 ENGINE C364M ...

Page 128: ...UPDATES ENGINE C216M 5 1 ENGINE C216M UPDATES ENGINE C216M 5 ...

Page 134: ...UPDATES ENGINE C216M 5 7 ENGINE C216M Slide the oil hose to remove the cooling case ...