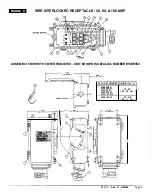

INSTALLATION INSTRUCTIONS FOR "WSR"

SERIES RECEPTACLES: 30, 60 & 100 AMP

INSTALLATION

1. PREPARE MOUNTING POSITION:

Owners are responsible for damages or injuries if these rules are not followed

WARNING

• Before starting with the installation, make sure the receptacle assembly is suitable for the intended location

according to the National Electrical Code or Canadian Elect

r

ical Code.

• If the receptacle assembly is not suitable, serious damage and injuries may result.

A. The receptacle assembly must be mounted on (4) 3/8" max. diameter steel, hex-head bolts per ANSI Bl8.2.l - 1981,

securely fastened to wall, column, strut or other vertical structure, in one plane, capable of supporting the receptacle, its

associated conduit and wiring. Please note that these bolts are not provided with the receptacle assembly.

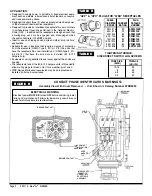

B. Referring to "FIGURE C" for dimensions of the "WSR" receptacles, prepare the structure for the mounting bolts

by drilling, tapping, securing nuts or another method of providing threaded anchors for the bolts ..

C. Install the bolts leaving 3/8" to 1/2" under the heads ..

• The bolts must be engaged at least five

(5)

full threads ..

2. MOUNTING THE RECEPTACLE:

A. Place the receptacle assembly on the previously prepared mounting bolts, with ·the receptacle face

(1)

at the

lower-most position ( See FIGURE C ).. Make sure that the shank of the bolts is in the small part of the key-hole slots

in all four cases. Tighten the bolts to 18 to

io

lbs-ft torque.

3. OPENING HOUSING COVER:

A. Referring to "FIGURE C", loosen the housing cover bolts (2), but do not attempt to remove them completely from the

cover

(3)

because they are designed to be captive.

B. The cover (3) is now free to swing open on its factory installed hinges (4)..

C. Although it is not necessary, the cover (3) can be removed f

r

om the housing (5) by carefully lifting the cover enough to

clear the hinge pins; approximately

.90

inches.

D. It is recommended that if removed, the cover be placed outer surface down on clean wood .. Then protect with a tarp or

other covering to maintain cleanliness and damage-free conditions.

4. CONDUIT INSTALLATION:

A. Note that a

1 1/2"

NPT conduit entry is provided on the top of the housing

(5).

An

1 1/2"

to

1 1/4"

and an

1 1/2"

to

1"

reducer bushings ar·e also provided and can be used if desired.

B. Make sure that conduit entry is clean and free of debris before installing conduit or reducer bushing.

C. Grease must be used on conduit and reducer bushing threads to completely seal out water.

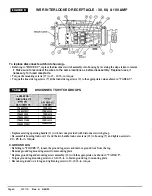

* Appleton Electric Company thread lubricant, part no. TLC-3, is recommended to be applied on threads in three

generous lines running parallel to the thread axis and spaced equidistant around the thread ..

D. Conduit must be turned in until snug and then

1/2

tum further with a wrench.

* Do not over-tighten as damage to the threads in the housing or reducer bushing may occu

r

.

5. WIRING:

WARNING

• The "WSR" receptacles a

r

e designed

and tested for use with copper

conductors only.

• DO NOT USE ALUMINUM WIRING

as dangerous overheating and fire

may result.

WARNING

Electrical power must be turned "off' before

and during installation and maintenance.

Failure to do so may result in

serious

I

fatal injuries due to

electrocution.

Page 4

330118

Rev. A 3/28/95