- 9 -

①

The silicone oil applied should not be too much. After wiping with micro-fiber cloth, please wipe

with filter paper or high-quality tissue paper to clean off. Excessive residual silicone oil on the

vial surface will affect the measurement accuracy.

②

It's not necessary to use silicone oil for each calibration and measurement. Apply silicone oil

every several days or once a week. In between, just clean the surface with filter paper or high-

quality tissue paper.

③

Clean the calibration vial and sample vial together and keep the steps and actions consistent to

achieve same degree of cleanliness.

④

Stability of calibration solutions

The U.S EPA approved AMCO polymer standard calibration solution is very uniform and stable.

It does not precipitate, drift or condense. It can be used directly without shaking or flipping the

vial (to make the solution even). For polymer calibration solutions that have not been used for a

long time, slowly flip the vial twice and let it stand for 2 minutes. Be careful not to shake the

solution vigorously, as this will create air bubbles which destabilize the measurement; For 0.0

NTU calibration solution, do NOT shake or flip. If using Formazin calibration solution, as it tends

to precipitate easily, each time users must flip and shake the vial to make the solution even. But

sediment can still occur during tests and make the measurement unstable. Operating

experience is important in using Formazin calibration solutions.

4.2

Calibration Procedure (Take 0 NTU and 20 NTU as an example)

1) Instrument warm up: Power on the instrument, and then wait for 3 minutes.

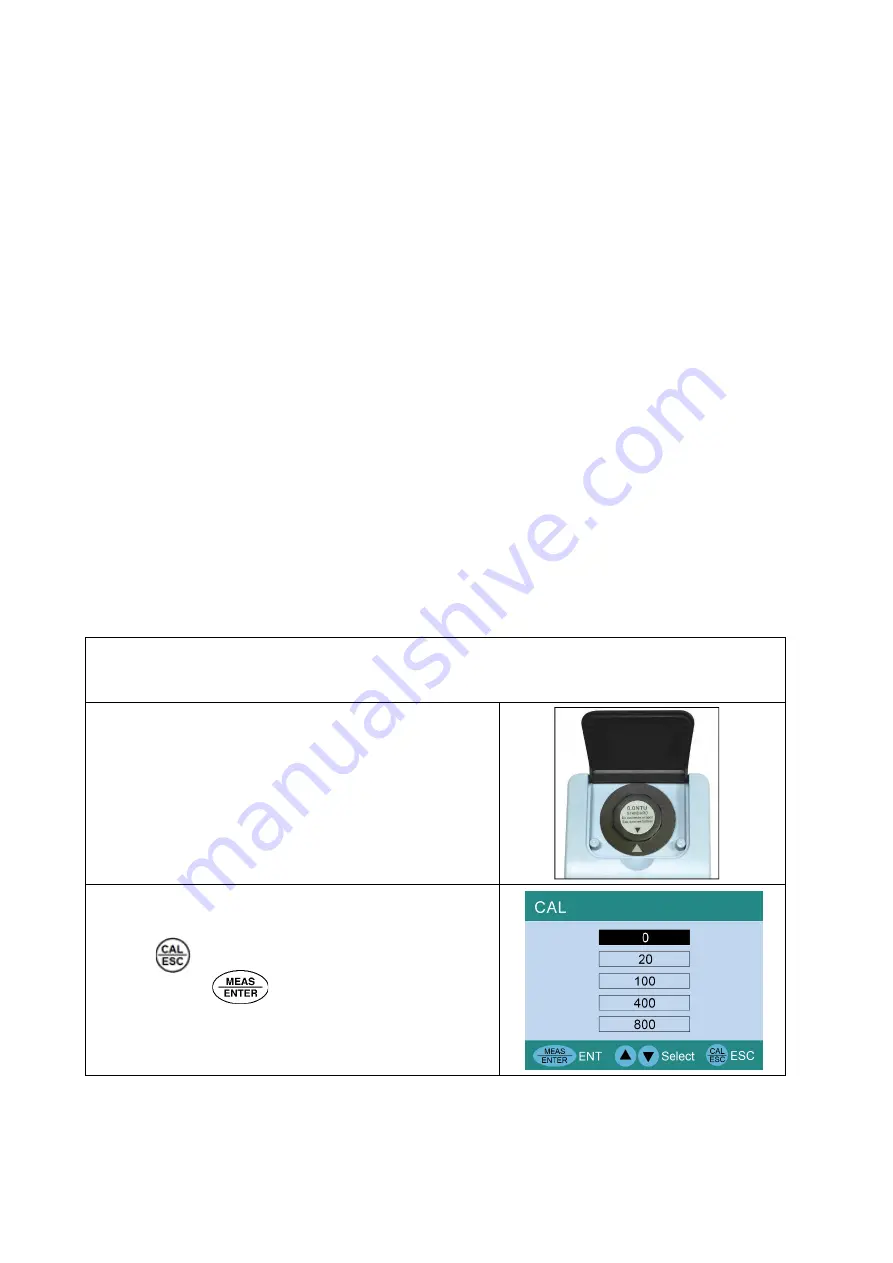

2) Open the flip cover and place the 0.0 NTU calibration

vial. Align the arrow on the vial lid with the one on the

sample vial holder and close the flip cover.

3) Press to enter the calibration menu, the cursor is

at 0 NTU. Press to start calibration.