Aode Machinery Co., Ltd Page 22 of 26

奥德机械有限公司

2012

第八章

异常情况及处理表

Chapter Eight Abnormal Situation and Solution

故障现象

Phenomena

原因

Causes

处理方法

Solutions

1

、无法开机

Fail to start up.

1

、控制电路开关未打开

Fail to open the controlling circuit

switch

1

、将微型断路器开关打开

Open the micro breaker switch

2

、欠相。

Default phase.

2

、检查电源线。

Check the power wire.

3

、高压断电保护

High voltage power off

protection

3

、打开机器侧封板,按下压力开关红色复位键

即可

Open the machine side boards, press the red

reset button of pressure switch

2

、缺水警报

Water shortage alarm.

1

、未开冷却水或压力不够

The cooling water is not opened

or the pressure is not enough.

1

、打开冷却水阀门并检查压力情况。

Open the cooling water valve and check the

pressure.

2

、冷却水进出口接反

The position of the cooling water

inlet and outlet is not right

2

、调换冷却水进出口

Exchange the position of the cooling water

inlet and outlet

3

、冷却水或补水口过滤器堵塞

Cooling water or filling water port

blocked

3

、清洗过滤器

Clean up the filter

3

、泵过载警报

Pump overload

alarming.

1

、系统负载过重

System overload.

1

、

05A,10A

检查热水出入口阀门是否开启,并

按复归键。

Check if the hot water inlet/outlet valve is

open and press the reset key.

2

、

检查泵的电机是否卡死

Check if the motor of pump is stuck

2

、电源电压不正常或欠相

Abnormal power supply or

voltage, or phase deficiency.

1

、

使用三相电表测三相电压和电流。

Use three-phase electric meter to measure

three phase voltage and electricity.

2

、

检查电源端子是否松脱并拧紧,并按复归

键。

Check if the power supply terminal is

loosened, if yes, please screw it and press the

reset key.

3

、

电机轴承卡死

Motor bearing stuck

3

、更换轴承

Replace the bearing

4

、温度偏高、无法降温

Temperature is too high

to fall down

1

、电磁阀堵塞。

Solenoid valve blocked.

1

、清除电磁阀内水孔杂物并清洗。

Clear up the sundries of water hole in solenoid

valve.

2

、电磁阀线圈老化损坏。

Loop of solenoid valve aging and

damaged.

2

、请来电我司。

Please call us.

3

、冷却水出水被压太大

The pressure of cooling water is

too big

3

、冷却水出口直接排空或检查冷却水进出口是

否接反

Cooling water emptying directly or check the

position of the cooling water inlet and outlet

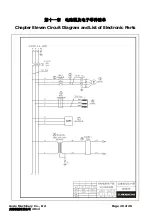

Summary of Contents for AWM-05

Page 10: ...Aode Machinery Co Ltd Page 9 of 26 2012 4 2 Pump performance curve...

Page 11: ...Aode Machinery Co Ltd Page 10 of 26 2012...

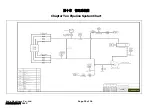

Page 15: ...Aode Machinery Co Ltd Page 14 of 26 2012 5...

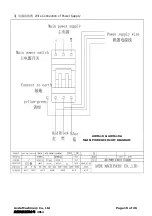

Page 22: ...Aode Machinery Co Ltd Page 21 of 26 2012...

Page 26: ...Aode Machinery Co Ltd Page 25 of 26 2012 Chapter Ten Pipeline System Chart...

Page 28: ...Aode Machinery Co Ltd Page 27 of 26 2012...

Page 29: ...Aode Machinery Co Ltd Page 28 of 26 2012...

Page 30: ...Aode Machinery Co Ltd Page 29 of 26 2012...

Page 31: ...Aode Machinery Co Ltd Page 30 of 26 2012...