2

Preparation

1.

After opening all boxes and packages, read this introduction carefully. Check that all of the needed

parts are included in the package by marking all the components on the “Detailed Diagram of

Shower Door Components”. Examine boxes and packages for shipping damage. If the unit has

been damaged, has a finishing defect, or is missing parts, please contact our customer support

department within 5 business days of the delivery date. Please note that

We will not replace

any damaged products or missing parts free of charge after 5 business days or if the products

has been installed.

Feel free to contact us if you have any questions..

2.

Please note that you should consult your local building codes with questions on installation

compliance standards. Building and plumbing codes may vary by location, and we are not

responsible for code compliance standards for your project and will not accept any

returns.

3.

Prior to installation, ensure that the installation surface is leveled and solid and will be able to

support the total weight of the unit. Also, make sure the walls are at right angles. Irregular

installation surface level or improper angle of side walls will result in serious problems for your

installation. Please, note that some adjustments and drilling might be necessary during the

installation process.

4.

This unit has to be installed against a finished floor and walls.

5.

Please, NOTE! This door does not have out-of-plumb adjustment. Make sure your walls are

at right angles.

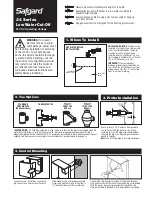

Tools Required

Caulk

Tape

Measure

Pencil

Screwdriver

Phillips

(Ø 5/16")

Drill bit

Level

Gun

Caulk

Drill

Electric

Hammer

Knife

(Ø 1/8")

Drill bit

Summary of Contents for SD-AZ03-01

Page 1: ......