15

Electronics Assembly Instructions

Step 4:

Attach the CAN Connector (am-4130) to the

Bottom Plate using two (2) #10-32 x 0.5 long inch

Button Head Cap Screws (am-1512) and #10-32

Nylock Jam Nuts (am-1063) on the underside of the

Bottom Plate. Be sure to orient the CAN Connector

such that the wire terminals face away from the

PowerPole Distribution Board.

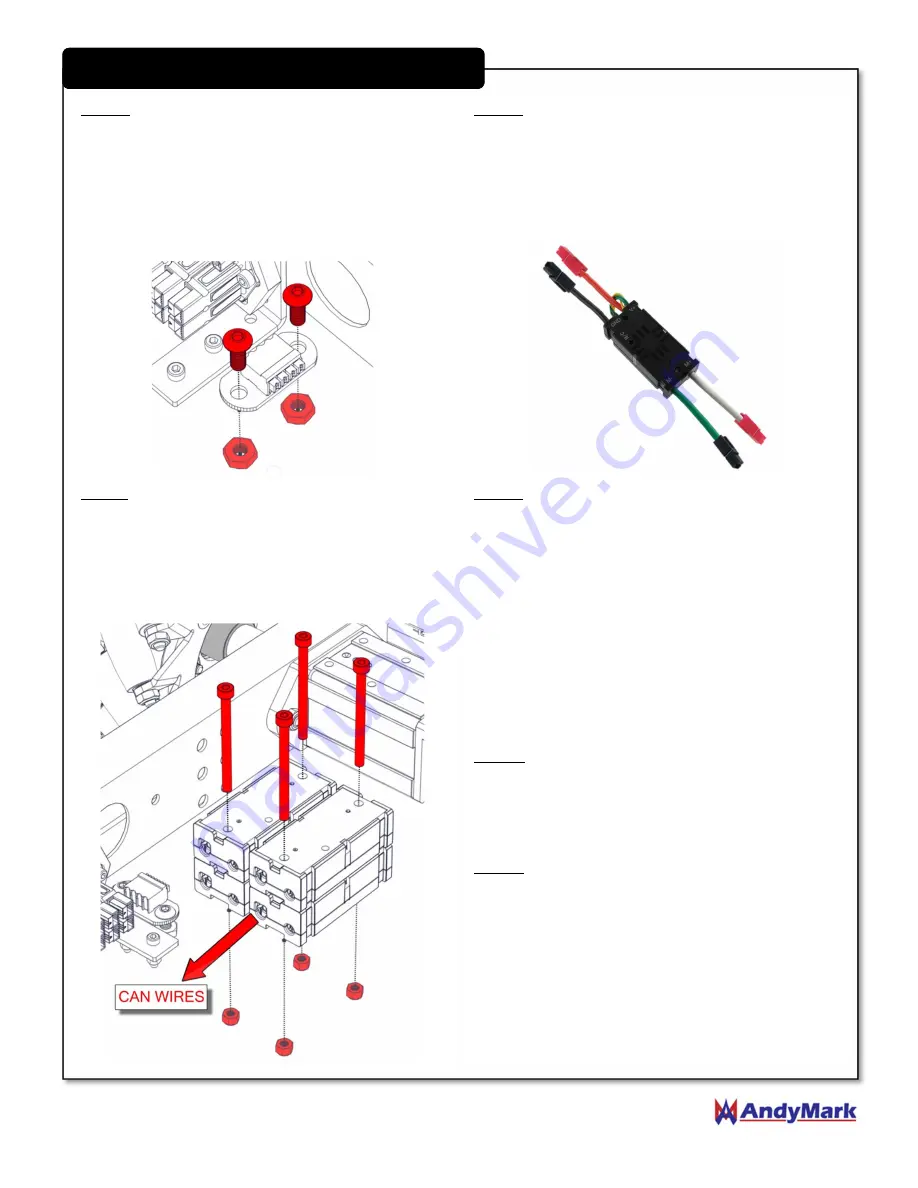

Step 5:

Add PowerPoles (am-2198) to the four power

leads on each Victor SPX. Red PowerPoles should be

added to the Red and White leads and black

PowerPoles should be added to the Black and Green

leads. A PowerPole Crimp Tool (am-2554) (sold

separately) should be used to ensure a proper crimp.

Step 6:

Add four (4) Victor SPX Speed Controllers (am-

3748) in two stacks of two with the CAN wires

oriented facing towards the CAN Connector. Use four

(4) M4x50 Socket Head Cap Screws (am-1401) and M4

Nylock Nuts (am-1435) to secure the controllers to

the top of the Bottom Plate.

Step 7:

Cut one pair of CAN (yellow and green) wires

on one of the bottom Victors to approximately 3

inches long. Save the cut off wire for use in Step 9.

Strip the ends of the remaining wires and crimp 20

AWG White Ferrules (am-3738_20) onto each wire.

Insert the yellow wire into the CAN Connector in one

of the “HI” terminals and the green wire into one of

the “LO” terminals. Insert the legs of the CAN Resistor

(am-4111) into the remaining “HI” and “LO”

terminals.

Step 8:

Connect the remaining CAN wires together

leaving one pair (from any Victor) open. Secure the

connections with the provided retainer clips

Step 9:

Connect the cut off wire from Step 7 to the

remaining open pair of wires from Step 8. Strip the

cut ends of the pair of wires and crimp 20 AWG White

Ferrules (am-3738_20) onto each wire.