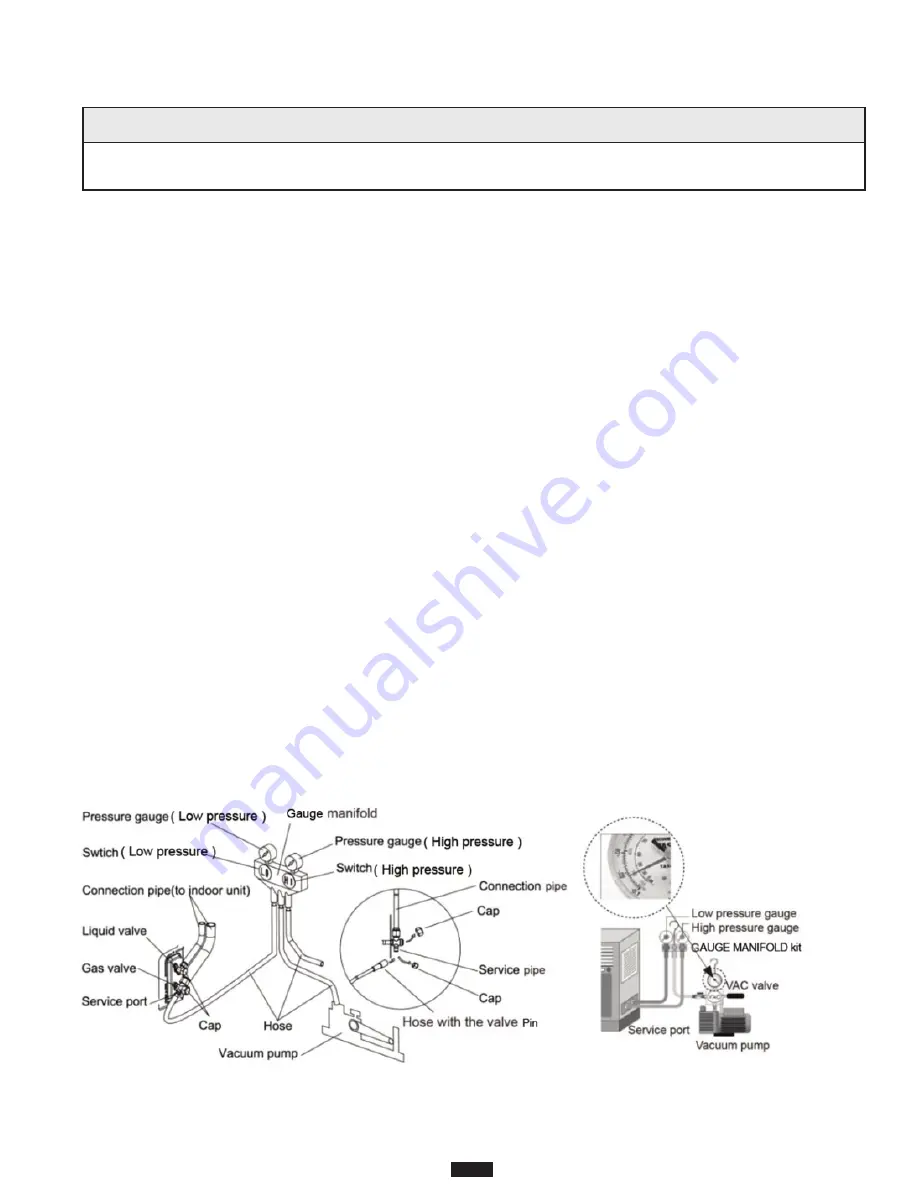

Vacuum

1. Remove the caps of the liquid valve, gas valve and service port.

2. Connect the hose at the low pressure side of the manifold valve assembly to the service port

of the unit's gas valve. The gas and liquid valves should be kept closed in case of refrigerant

leakage.

3. Connect the hose used for evacuation to the vacuum pump.

4. Evacuate until the micron gauge reads no higher than 350 microns, then close off the valve to

the vacuum pump. IMPORTANT: Do not open the service valves until the refrigerant lines and

the indoor coil leak check and evacuation are complete.

5. Observe the micron gauge. Evacuation is complete if the micron gauge does not rise above

500 microns in one (1) minute.

6. When evacuation is complete blank off the vacuum pump and micron gauge, and close the

valves on the manifold gauge set.

7. Open the liquid valve slightly and let some refrigerant go to the connection pipe to balance the

pressure inside and outside of the connection pipe, so that air will not come into the connection

pipe when removing the hose. Note that the gas and liquid valve can be opened fully only after

the manifold valve assembly is removed.

8. Put the caps back on the liquid valve, gas valve and service port.

Vacuum and Refrigerant Leakage Detection

NOTICE

Do not purge the air with refrigerant. Use a vacuum pump to vacuum the installation! There is no

extra refrigerant in the outdoor unit for air purging!

Leakage Detection

1. Check if there is leakage at all connection points with a leakage detector.

2. If a leakage detector is not available, please use soapy water. Apply the soapy water at the

suspected position and let sit for a few minutes. If bubbles appear, there is a leak that must be

repaired.

22

15 SEER Mini-Split

Summary of Contents for M4MHW15-A

Page 39: ......