12

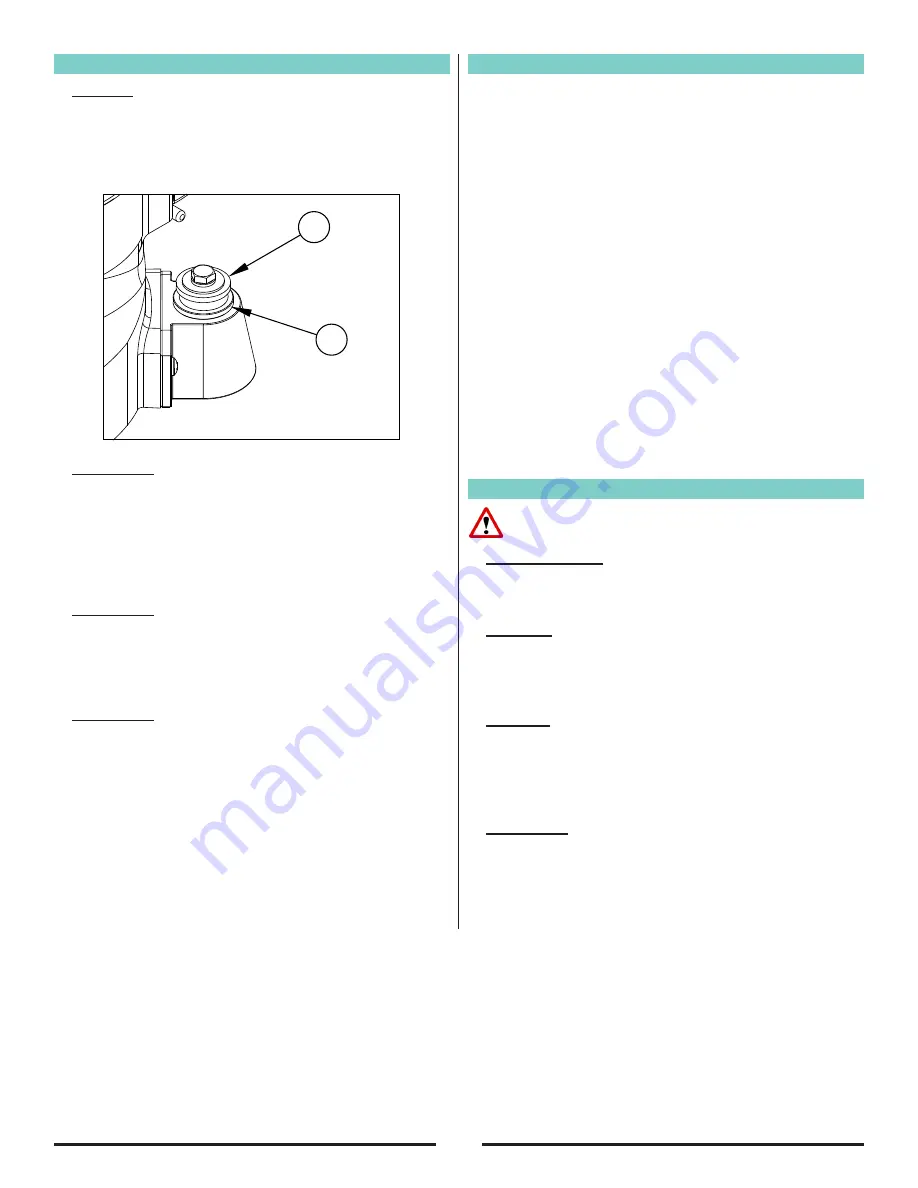

A

B

Adjustment Procedures

Leveling

To level machine: Grasp caster adjusting screw “A”

with an appropriate tool (pliers etc.). Using a similar

tool, loosen locknut “B” with a counter clockwise

motion. (Figure 6).

Condition 1

: Pad creates ridges on both edges or a

“hop” is experienced.

Rotate both adjusting screws equal amounts

clockwise. Tighten locknut’s and test on a piece

of plywood. Repeat procedure until condition is

corrected. We recommend you not exceed 1/8”

rotation for each attempt.

Condition 2

: Pad creates a ridge on the tip of the pad.

Rotate both adjusting screws counter clockwise,

tighten locknut’s and test. Repeat procedure until

condition is corrected. Use only 1/8 rotation for each

attempt.

Condition 3

: Pad creates a ridge on only one side of the

pad.

Either rotate the adjusting screw of the side effected

clockwise or rotate the adjusting screw opposite

counterclockwise, depending on whether the ridge

terminates beyond the tip of the pad or prior to it. If it

is prior to the tip, adjust the side effected, otherwise

adjust the opposite side.

Sanding Cuts & Sandpaper

Initial Cut

:

The purpose of the initial cut is to remove old finish and

gross imperfections on the floor surface. Use a course

(20-36 grit) grain abrasive.

If glazing, loading, or burning takes place

immediately into an initial cut, select a coarser

abrasive. If this should occur during an initial cut, the

abrasive has dulled and must be replaced.

Final Cuts

:

The purpose of a finishing cut is to remove the

scratches produced during the initial cut. Use a fine (60-

80 grit) grain abrasive.

If the surface remains rough after a finishing cut, it may

be necessary to use an even finer grain of abrasive (80-

100grit). Care should be taken in selecting the grit size

of the abrasive. A very fine grain will close the pores

on a wood floor making admission of a stain difficult. If

glazing or burning should occur the abrasive has dulled

and must be replaced.

Routine Maintenance

CAUTION

: Failure to perform maintenance at

recommended intervals may void warranty.

Carbon Brushes

Have the carbon brushes replaced at least every 500

hours and more frequently under heavy use.

Dust Bag

Periodically the dust bag should be turned inside out,

shaken vigorously and machine washed in cold water

to prevent pore blockage and loss of dust control.

Bearings

To insure reliable performance, have armature and

pad driver bearings inspected for wear or damage

after every 1500 hours. If used heavily, have the

bearings replaced seasonally.

Lubrication

The machine comes fully lubricated. The gears in the

gear box have enough lubrication for approximately

six months of normal operation. Have the lubricant

changed at least every 6 months or more frequently

under heavy use.

Figure 6

Summary of Contents for American Sanders Super 7R 240V

Page 1: ...Edger Super 7R 240V Operator s Manual...

Page 2: ......

Page 15: ...Electrical Schematic 15...

Page 22: ......