5

Leak test the system using dry nitrogen and soapy

water to identify leaks. If you prefer to use an electronic

leak detector, charge the system to 10 PSIG with the

appropriate system refrigerant (see Serial Data Plate

for refrigerant identification). Do not use an alternative

refrigerant. Using dry nitrogen finish charging the system

to 450 PSIG. Apply the leak detector to all suspect areas.

When leaks are discovered, repair the leaks, and repeat

the pressure test. If leaks have been eliminated proceed to

system evacuation.

System Evacuation

Condensing unit liquid and suction valves are closed to

contain the charge within the unit. The unit is shipped with

the valve stems closed and caps installed.

Do not open

valves until the system is evacuated.

WARNING

REFRIGERANT UNDER PRESSURE!

Failure to follow proper procedures may cause property

damage, personal injury or death.

NOTE: Scroll compressors should never be used

to evacuate or pump down a heat pump or air

conditioning system.

CAUTION

Prolonged operation at suction pressures less than 20 psig

for more than 5 seconds will result in overheating of the

scrolls and permanent damage to the scroll tips, drive

bearings and internal seal.

Deep Vacuum Method (Recommended)

The Deep Vacuum Method requires a vacuum pump

rated for 500 microns or less. This method is an effective

and efficient way of assuring the system is free of non-

condensable air and moisture. As an alternative, the Triple

Evacuation Method is detailed in the Service Manual for

this product model.

It is recommended to remove the Schrader Cores from the

service valves using a core-removal tool to expedite the

evacuation procedure.

1. Connect the vacuum pump, micron gauge, and

vacuum rated hoses to both service valves.

Evacuation must use both service valves to eliminate

system mechanical seals.

2.

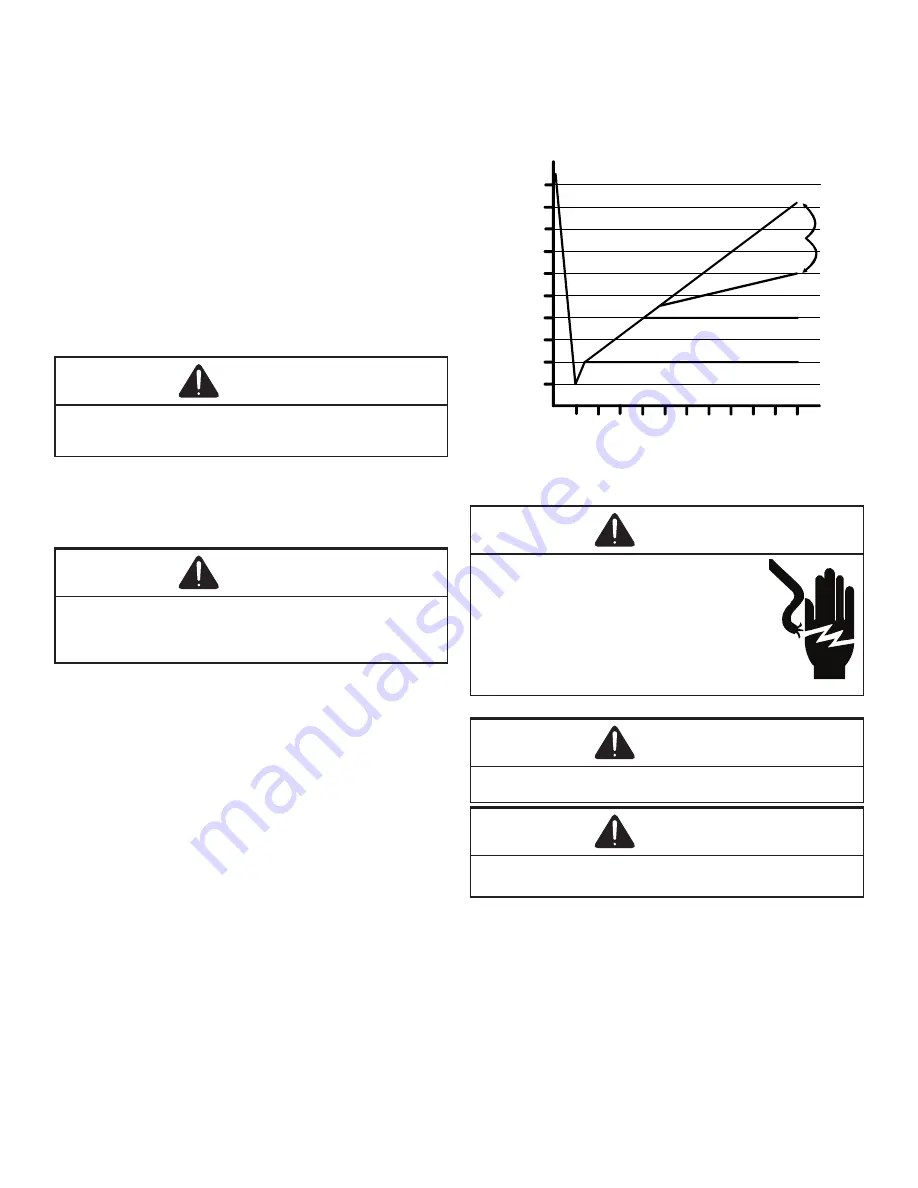

Evacuate the system to less than 500 microns.

3. Isolate the pump from the system and hold vacuum

for 10 minutes (minimum). Typically, pressure will rise

slowly during this period. If the pressure rises to less

than 1000 microns and remains steady, the system is

considered leak-free; proceed to system charging and

startup.

4. If pressure rises above 1000 microns but holds steady

below 2000 microns, non-condensable air or moisture

may remain or a small leak is present. Return to step

2: If the same result is achieved check for leaks and

repair. Repeat the evacuation procedure.

5. If pressure rises above 2000 microns, a leak is

present. Check for leaks and repair. Repeat the

evacuation procedure.

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

0 1 2 3 4 5 6 7 8 9 10

LEAK(S)

PRESENT

MINUTES

V

ACU

UM

IN

MI

CR

O

NS

CONDENSIBLES OR SMALL

LEAK PRESENT

NO LEAKS

NO

CONDENSIBLES

ELECTRICAL CONNECTIONS

WARNING

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death due to electric

shock. Wiring must conform with NEC or CEC

and all local codes. Undersized wires could

cause poor equipment performance, equipment

damage or fire.

WARNING

To avoid the risk of fire or equipment damage, use copper

conductors.

NOTICE

Units with rotary or reciprocating compressors and non-

bleed TXV’s require a Hard Start Kit.

The condensing unit rating plate lists pertinent electrical

data necessary for proper electrical service and

overcurrent protection. Wires should be sized to limit

voltage drop to 2% (max.) from the main breaker or fuse

panel to the condensing unit. Consult the NEC, CEC, and

all local codes to determine the correct wire gauge and

length.

Local codes often require a disconnect switch located near

the unit; do not install the switch on the unit. Refer to the

installation instructions supplied with the indoor furnace/

air handler for specific wiring connections and indoor unit