23

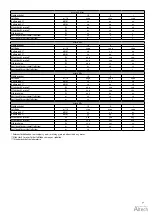

Model:

Altech VR Mini EC

Altech VR1/VR2 EC

Altech VR3 EC

1.

28.5%

27.5%

28%

2.

B

3.

Static

4.

21

5.

VSD-No

6.

2016

7.

Dahl Sverige AB, Bryggerivägen 9, Box 11076, 168 67 Bromma Stockholm

8.

1-2-2701-0304

1-2-2701-0289

1-2-2701-0290

9.

0,41kW, 2826 m

3

/h, 145Pa

0,48kW, 4239 m

3

/h, 124Pa

0,68kW, 6006 m

3

/h, 128Pa

10.

1376RPM

1370RPM

1372RPM

11.

1,0

12.

Disassembly of the machine must be carried out and/or supervised by qualified personnel with appropriate expert knowledge.

Contact a certified waste disposal organization in your vicinity. Clarify what is expected in terms of the quality of dismantling the

machine and provision of the components.

Dismantle the machine using the general procedures commonly used in mechanical engineering.

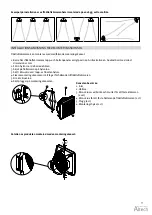

WARNING

Machine parts can fall. The machine is made up of heavy parts. These parts are liable to fall during dismantling. This can

result in death, serious injury, or material damage.

Follow the safety rules:

1. Disconnect all electrical connections.

2. Prevent reconnection.

3. Make sure that the equipment is at zero voltage.

4. Cover or isolate nearby components that are still live.

To energize the system, apply the measures in reverse order.

Components:

The machines consist for the most part of steel and various proportions of copper, aluminum and plastics and rubberneoprene

(seat of bearings/hub, gasket). Metals are generally considered to be unlimitedly recyclable.

Sort the components for recycling according to whether they are:

Iron and steel, aluminum, non-ferrous metal, e.g. windings (the winding insulation is incinerated during copper recycling),

insulating materials, cables and wires, electronic waste (capacitor ect.), plastic parts (impeller, junction box, winding cover ect.),

rubber parts (neoprene). The same goes for cloths and cleaning substances which have been used while working on the machine.

Dispose of the separated components according to local regulations or via a specialist disposal company.

13.

Long failure-free operation depends on keeping the product/device/fan within performance limitations described by selection

software or maintenance manual.

For proper operation, read carefully maintenance manual, with special attention on “installation”, “start-up”, and “maintenance”

chapters.

14.

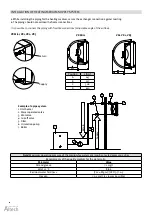

Inlet ring, fan grid.

1. General efficiency (

η

)

2. Measurement category used to determine the energy efficiency

3. Efficiency category

4. Efficiency coefficient in the point of optimal energy efficiency

5. Whether rotational speed regulation was taken into account in the calculation of fan efficiency

6. Year of manufacture

7. Manufacturer’s name or trademark, business register number and place of manufacture

8. Product model number

9. Rated motor power consumption (kW), flow volume and pressure in the point of energy efficiency

10. Rotations per minute in the point of energy efficiency

11. Characteristic coefficient

12. Essential information to facilitate disassembly, recycling or dispose of the product after the end of its use

13. Essential information to minimize the effect on the environment and to guarantee optimum use period, referring to disassembly, use and technical

service of the fan

14. Description of additional elements used in determining the energy efficiency of the fan

Summary of Contents for VR Mini

Page 1: ...Heating unit Fl ktluftv rmare VR Mini VR1 VR2 VR3 1 12 Check us on EN Manual SV Manual...

Page 24: ...24 Notes...

Page 46: ...46 Anteckningar...

Page 47: ...47 Anteckningar...