506724-01

Page 19 of 57

Issue 1108

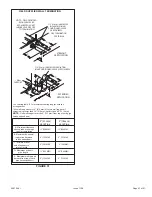

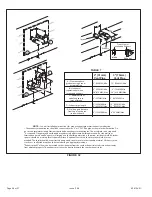

TABLE 5 Continued

A95UH and 95G1UH Maximum Allowable Intake or Exhaust Vent Length in Feet

*Size intake and exhaust pipe length separately. Values in table are for Intake OR Exhaust, not combined total. Both Intake and Exhaust must be same pipe size.

Standard Termination at Elevation 0 − 4,500

Number Of

90° Elbows

Used

2" Pipe

2−1/2" Pipe

3" Pipe

Model

Model

Model

045

070

090

110

135

045

070

090

110

135

045

070

090

110

135

1

76

61

39

19

n/a

110

95

63

38

n/a

132

132

113

113

109

2

71

56

34

14

105

90

58

33

127

127

108

108

104

3

66

51

29

9

100

85

53

28

122

122

103

103

99

4

61

46

24

n/a

95

80

48

23

117

117

98

98

94

5

56

41

19

90

75

43

18

112

112

93

93

89

6

51

36

14

85

70

38

13

107

107

88

88

84

7

46

31

9

80

65

33

8

102

102

83

83

79

8

41

26

n/a

75

60

28

n/a

97

97

78

78

74

9

36

21

70

55

23

92

92

73

73

69

10

31

16

65

50

18

87

87

68

68

64

Concentric Termination Elevation 0 − 4,500

Number Of

90° Elbows

Used

2" Pipe

2−1/2" Pipe

3" Pipe

Model

Model

Model

045

070

090

110

135

045

070

090

110

135

045

070

090

110

135

1

68

53

37

17

n/a

100

85

59

34

n/a

116

116

109

109

100

2

63

48

32

12

95

80

54

29

111

111

104

104

95

3

58

43

27

7

90

75

49

24

106

106

99

99

90

4

53

38

22

n/a

85

70

44

19

101

101

94

94

85

5

48

33

17

80

65

39

14

96

96

89

89

80

6

43

28

12

75

60

34

9

91

91

84

84

75

7

38

23

7

70

55

29

n/a

86

86

79

79

70

8

33

18

n/a

65

50

24

81

81

74

74

65

9

28

13

60

45

19

76

76

69

69

60

10

23

8

55

40

14

71

71

64

64

55

Standard Termination at Elevation 4,501 − 10,000

Number Of

90° Elbows

Used

2" Pipe

2−1/2" Pipe

3" Pipe

Model

Model

Model

045

070

090

110

135

045

070

090

110

135

045

070

090

110

135

1

76

61

39

n/a

110

95

63

38

n/a

132

132

113

113

109

2

71

56

34

105

90

58

33

127

127

108

108

104

3

66

51

29

100

85

53

28

122

122

103

103

99

4

61

46

24

n/a

95

80

48

23

117

117

98

98

94

5

56

41

19

90

75

43

18

112

112

93

93

89

6

51

36

14

85

70

38

13

107

107

88

88

84

7

46

31

9

80

65

33

8

102

102

83

83

79

8

41

26

n/a

75

60

28

n/a

97

97

78

78

74

9

36

21

70

55

23

92

92

73

73

69

10

31

16

65

50

18

87

87

68

68

64

Concentric Termination Elevation 4,501 − 10,000

Number Of

90° Elbows

Used

2" Pipe

2−1/2" Pipe

3" Pipe

Model

Model

Model

045

070

090

110

135

045

070

090

110

135

045

070

090

110

135

1

68

53

37

n/a

100

85

59

34

n/a

116

116

109

109

100

2

63

48

32

95

80

54

29

111

111

104

104

95

3

58

43

27

90

75

49

24

106

106

99

99

90

4

53

38

22

n/a

85

70

44

19

101

101

94

94

85

5

48

33

17

80

65

39

14

96

96

89

89

80

6

43

28

12

75

60

34

9

91

91

84

84

75

7

38

23

7

70

55

29

n/a

86

86

79

79

70

8

33

18

n/a

65

50

24

81

81

74

74

65

9

28

13

60

45

19

76

76

69

69

60

10

23

8

55

40

14

71

71

64

64

55