Page 15 of 18

506762-03

Issue 1946

Defrost System

The defrost system includes two (2) components: a defrost

thermostat and a control board.

Defrost Thermostat

The defrost thermostat is located on the outdoor coil of

most models and on the liquid line between the check/

expansion valve and the distributor on R-410A TXV

equipped models. When defrost thermostat senses 29°F

(42°F on R-410A TXV’s) or cooler, the thermostat contacts

close and send a signal to the control board to start the

defrost timing. It also terminates defrost when the liquid

line warms up to 60°F.

Control Board

The control board includes the combined functions of a

time/temperature defrost control, defrost relay, diagnostic

LEDs and terminal strip for field wiring connections.

The control provides automatic switching from normal

heating operation to defrost mode and back. During

compressor cycle, the control accumulates compressor run

times at 30-, 60-, or 90-minute field-adjustable intervals.

If the defrost thermostat is closed when the selected

compressor run time interval ends (call for defrost), the

defrost relay is energized and defrost begins. The factory

setting is 90 minutes which is the optimum efficiency

setting.

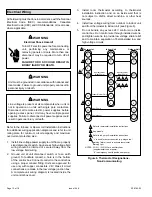

Defrost Timing Pins

Each timing pin selection provides a different accumulated

compressor run time period for one defrost cycle. This

time period must occur before a defrost cycle is initiated.

The defrost interval can be adjusted to 30 (/T1), 60 (T2),

or 90 (T3) minutes. If the timing selector jumper is not in

place the control defaults to a 90-minute defrost interval.

The maximum defrost period is 14 minutes and cannot be

adjusted.

A TEST option is provided for troubleshooting. The TEST

mode may be started any time the unit is in the heating

mode and the defrost thermostat is closed or jumpered. If

the jumper is in the TEST position at power-up, the control

will ignore the test pins. When the jumper is placed across

the TEST pins for 2 seconds, the control will enter the

defrost mode. If the jumper is removed before an additional

5 second period has elapsed (7 seconds total), the unit will

remain in defrost mode until the defrost thermostat opens

or 14 minutes have passed. If the jumper is not removed

until after the additional 5 second period has elapsed, the

defrost will terminate and the test option will not function

again until the jumper is removed and re-applied.

Time Delay

The timed-off delay is 5 minutes long. The delay helps

to protect the compressor from short-cycling in case the

power to the unit is interrupted or a pressure switch opens.

The delay is bypassed by placing the timer select jumper

across the TEST pins for 0.5 seconds.

Compressor Delay

The defrost board has a field-selectable function to reduce

occasional sounds that may occur while the unit is cycling

in and out of the defrost mode. When a jumper is installed

on the DELAY pins, the compressor will be cycled off for

30 seconds going in and out of the defrost mode. Units are

shipped with jumper installed on DELAY pins.

NOTE:

The 30 second compressor delay feature (known

as the quiet shift)

must

be deactivated during any unit

performance testing. The feature is deactivated by

removing the jumper located on the compressor delay pins

on the control board mounted inside the unit control box.

This feature is optional for the homeowner, but may impact

testing performance.

Diagnostic LEDs

The state (Off, On, Flashing) of two LEDs on the defrost

board (DS1 [Red] and DS2 [Green]) indicate diagnostics

conditions that are described in Table 5.

Mode

Green LED (DS2)

Red LED (DS1)

No power to control

Off

Off

Normal operation /

power to control

Simultaneous slow flash

Anti-short cycle

lockout

Alternating slow flash

Low pressure switch

fault

Off

Slow flash

Low pressure switch

lockout

Off

On

High pressure switch

fault

Slow flash

Off

High pressure switch

lockout

On

Off

Table 5.