30

45-074, REV. 5/18

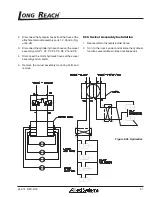

5.13 Cylinder Assembly

1. Spray the piston, gland cap and seals with WD40 or

other similar product to ease slipping of the seals in

place. (Figure 5-40)

2. Note the direction of the seal on the piston. Improper

installation will result in poor performance. The cupped

side or O-ring side of the seal should be facing the

gland cap. (Figure 5-45)

Cylinder Rod

Locknut

Piston

Wear Ring

Washer

Seal

O-Ring

Figure 5-45, Piston Seal

3. Use a spanner wrench or similar tool to unscrew the

gland cap from the cylinder tube. (Figure 5-42)

3. Install the seals and wipers in the gland cap. Note the

direction of the seals. The cupped side or O-ring side of

the seal should be facing the piston. (Figure 5-46)

F

H

Locknut

Piston

Seal

Wear Ring

Cylinder Rod

Cylinder Rod

Gland Cap

Wiper Ring

Seal

O-Ring

Backup

Ring

Figure 5-46, Gland Cap Seal

4. Install the piston on the rod and tighten the locknut to

70-75 ft-lbs.

5. Spray the inside of the cylinder tube with lubricant to

ease inserting the rod and piston. Insert the rod and

piston into the cylinder tube. Tap the rod in with a rub-

ber mallet if resistance is encountered.

6. Install the gland cap on the cylinder rod being extreme-

ly careful not to cut the rod seal on the threads of the

rod or rod shoulder. If available, use a sleeve or plastic

electrical tape to cover the rod threads.

7. Tighten the gland cap using a spanner wrench.

5.14 Swivel Assembly Removal

1. Turn off the truck’s power and activate the hydraulic

functions in both directions several times to relieve

the built up hydraulic pressure.