© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

9001909

18

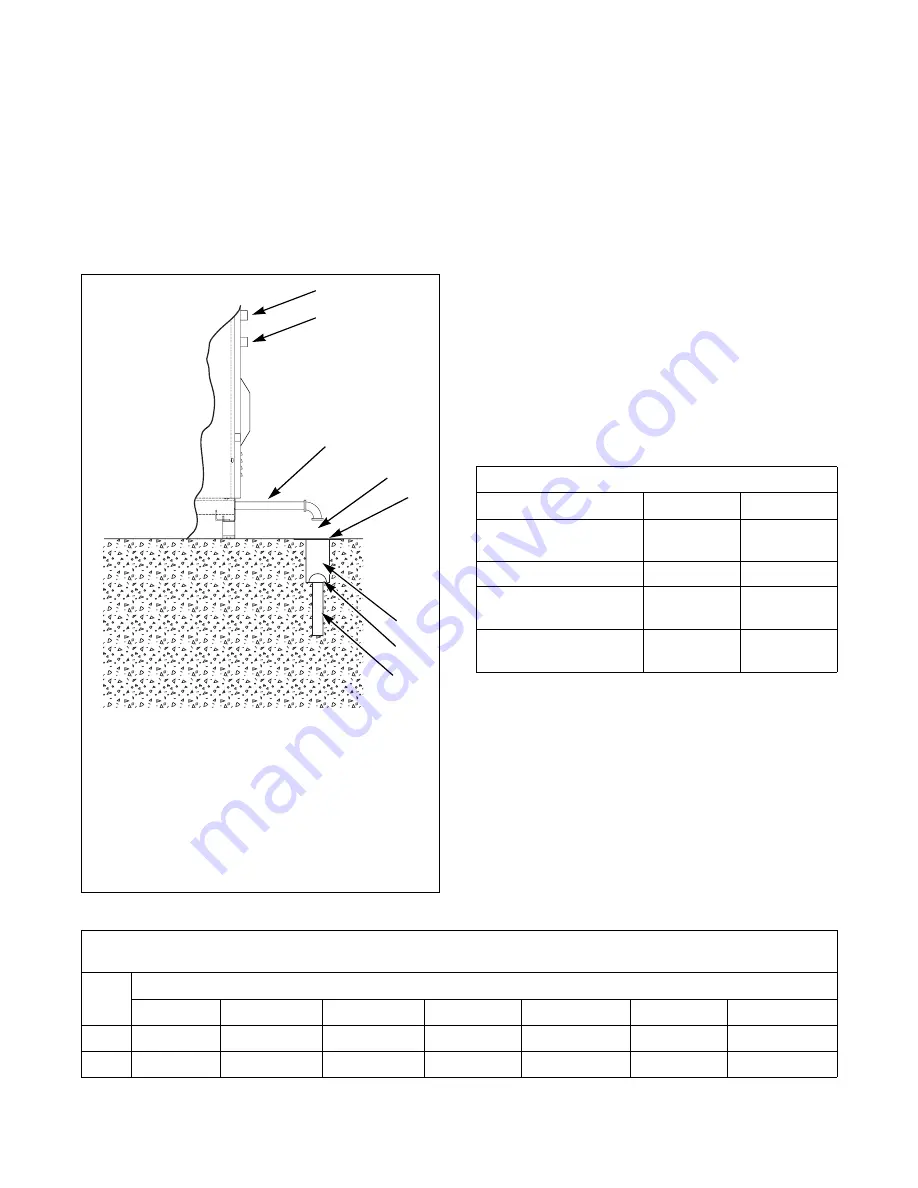

Drain Connection

A drain system of adequate capacity is essential to

washer-extractor performance.

Ideally, the water should empty through a vented pipe

directly into a sump or floor drain.

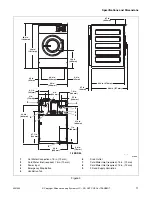

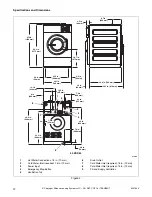

shows drain line and drain trough

configurations.

Figure 10

A flexible connection must be made to a vented or air

gap drain system to prevent an air lock and to prevent

siphoning. If proper drain size is not available or

practical, a surge tank is required. A surge tank in

conjunction with a sump pump should be used when

gravity drainage is not possible, such as in below-

ground-level installations.

Before any deviation from specified installation

procedures is attempted, the customer or installer

should contact the distributor.

Increasing the drain hose length, installing elbows, or

causing bends will decrease, impairing washer-

extractor performance.

Refer to

for capacity-specific drain

information.

Installation of additional washer-extractors will

require proportionately larger drain connections. Refer

to

.

CFS490N

1

Water Inlet

2

Water Inlet Air Gap

3

Drain Pipe

4

Waste Line Air Gap (if required)

5

Steel Grate

6

Drain Trough (if required)

7

Strainer (if required)

8

Waste Line

4

REAR OF MACHINE

3

5

6

1

7

8

2

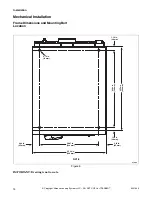

Drain Information

Model

18

30

Drain connection size, ID

2

in.

(51 mm)

2

in.

(51 mm)

Number of drain outlets

1

1

Drain flow capacity

20 gal/min

(76 l/min)

20 gal/min

(76 l/min)

Recommended drain pit

size

1.8 ft

3

(51 l)

2.5 ft

3

(70.3 l)

Table 3

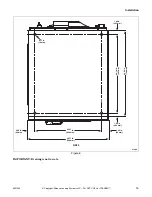

Drain Line Sizing

Minimum Drain ID

Model

Number of Machines

1

2

3

4

5

6

7

18

2

in.

(51 mm) 3

in.

(76.2 mm)

3 in.

(76 mm) 4

in.

(102 mm)

4 in.

(102 mm) 5 in. (124 mm) 5.5 in.(140 mm)

30

2

in.

(51 mm) 3

in.

(76.2 mm)

3.5 in.

(88 mm) 4

in.

(102 mm)

4.5 in.

(114 mm) 5 in. (124 mm) 5.5 in. (140 mm)

Table 4

Summary of Contents for NX18BVPA6

Page 2: ......