SECTION 2

OPERATIONS

064633

Page 40

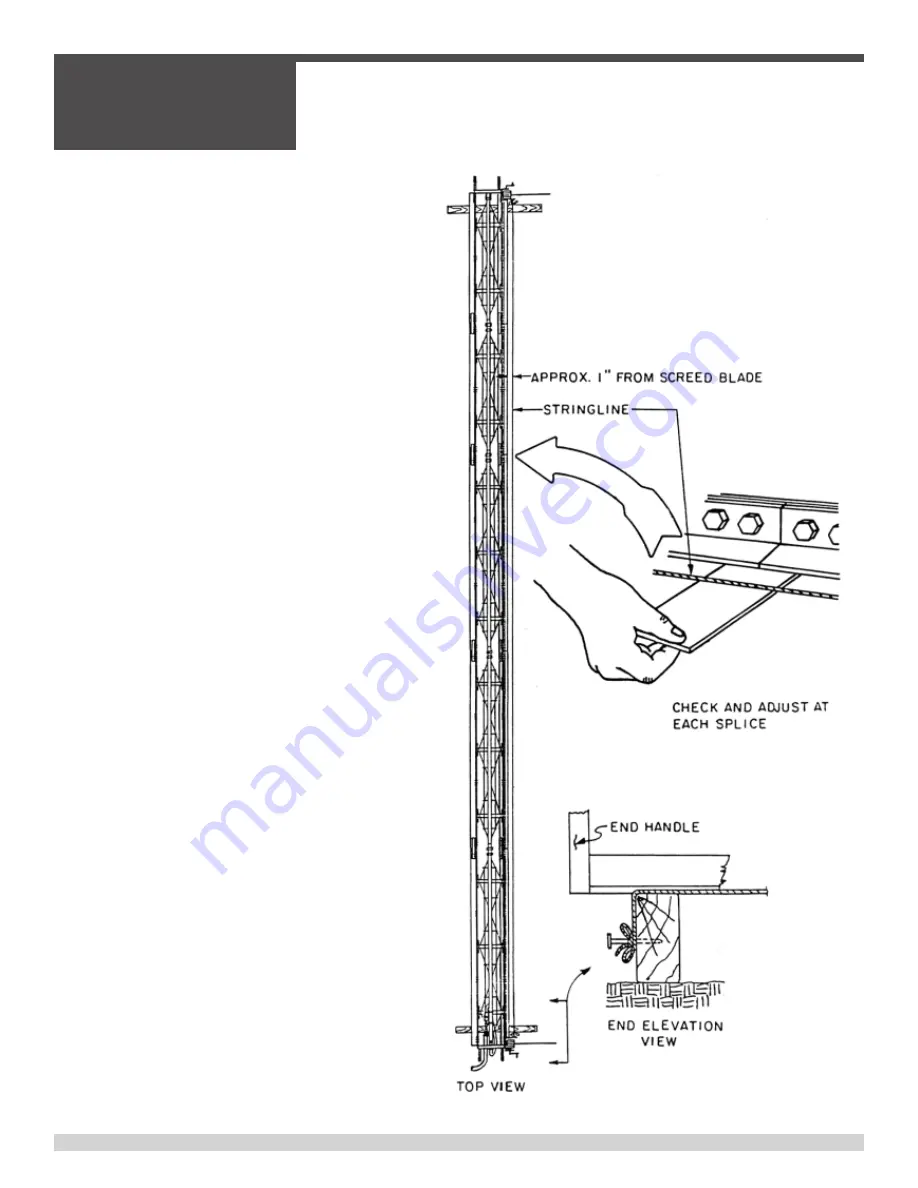

To string line your screed, there are a few im-

portant steps that need to be followed.

• Place screed ends on a 2 x 6 or other wooden

type support.

• At approximately 1” out from the leading

edge of the screed blade, drive a nail into the

wooden support. NOTE: Nail should be on the

outside of the wooden support.

• Stretch a line as tight as possible from nail to

nail. Make sure that the nail is contacting each

support at the pint of blade contact.

• NOTE: The supports do not have to be on the

same level.

•

Use a short, flat piece of metal or wood as a

gauge block to compare the string to the bot-

tom surface of the screed blade and bull-float

blade.

• The blades should be equal to each other at

each splice. If they are not even, loosen jam

nuts and tighten top pipe coupler as described

on page 33.

String Lining

Summary of Contents for SE12

Page 17: ...SECTION 1 SAFETY 064633 Page 17 SECTION 1 SAFETY ...

Page 18: ...SECTION 1 SAFETY 064633 Page 18 State Regulations Proposition 65 Warning ...

Page 19: ...SECTION 1 SAFETY 064633 Page 19 Federal Regulation Respiratory Hazard ...

Page 30: ...SECTION 1 SAFETY 064633 Page 30 Notes ...

Page 31: ...SECTION 2 OPERATIONS 064633 Page 31 SECTION 2 OPERATIONS ...

Page 41: ...SECTION 3 SERVICE 064633 Page 41 SECTION 3 SERVICE ...

Page 45: ...SECTION 4 PARTS 064633 Page 45 SECTION 4 Parts ...

Page 72: ...SECTION 4 PARTS 064633 Page 72 4 13 End Mount Engine Assembly Illustration ...