053257 - 01/2014

SECTION 3

SERVICE

Page 3-3

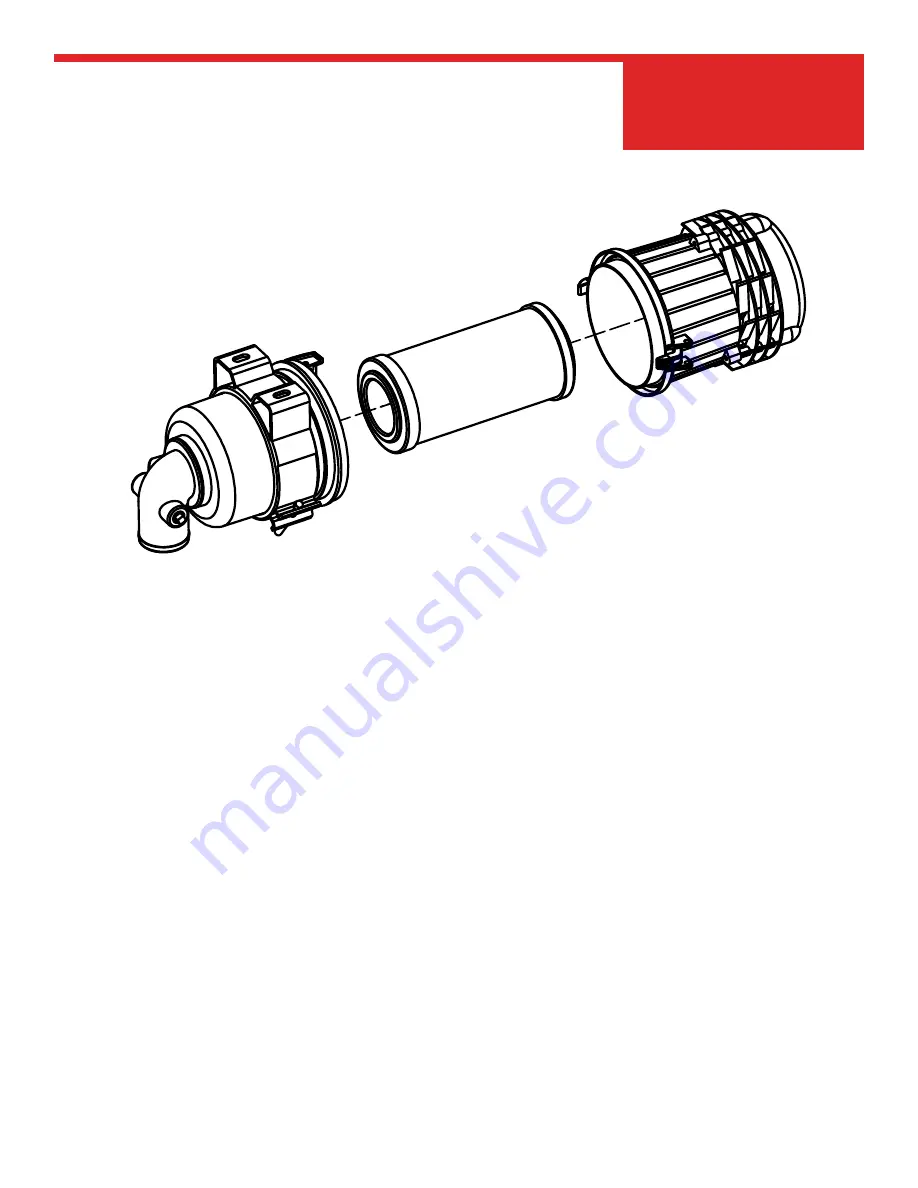

Pre-Cleaner Maintenance Procedure

This machine is equipped with a large capacity, dual element air

fi

lter.

When should you change an air

fi

lter? Many people believe that if a

fi

lter looks dirty it is no longer

working and should be changed. As stated above,

fi

lters need dirt to work properly. The key is knowing

when the

fi

lter is so dirty that to much energy is required by the engine to draw in air that it no longer

functions at it’s designed performance level.

Should you remove a

fi

lter to examine it? NO, never remove a

fi

lter until you are sure it needs to be

replaced. Most dust and dirt that enters your engine comes from over servicing the air

fi

lter. When an

air

fi

lter is removed, it’s seal is broken and dust and dirt that is in the air

fi

lter canister, now has a clear

path into your engine.

Use a Dust Load Indicator (DLI) to tell you when to change the

fi

lter. Dust Load Indicators take the

guess work out of air

fi

lter changes. The DLI is a vacuum sensitive device that “pops” of and shows you

red when it is time to change

fi

lters. If it is not red, don’t open the

fi

lter and allow more dirt to enter into

the engine. If it is red, carefully remove the

fi

lter cover and immediately vacuum the canister to remove

loose dirt. Then slowly remove the

fi

lter being careful not to disturb the dirt that may have become

caked around the seal of the

fi

lter. Again vacuum the canister, and then wipe the sealing area with a

damp cloth to insure no dirt can get into your engine. Replace the

fi

lter immediately with either a new

one or one that has been properly cleaned.

How do you clean an air

fi

lter?

NEVER use high powered air or “bang” it against something hard!

By doing so you can tear the paper or damage the sealing area and thus render the

fi

lter worse than

useless. Paper

fi

lters can be cleaned by carefully vacuuming their surface with a soft brush and thus

remove loose dust.

Air Filter Maintenance

Summary of Contents for MSP470A

Page 1: ...OPERATIONS PARTS MANUAL 053257 01 2014 Riding Trowel...

Page 14: ...053257 01 2014 Page xii Dimensional Speci cations...

Page 16: ...053257 01 2014 INTENTIONALLY BLANK Page xiv...

Page 17: ...053257 01 2014 SECTION 1 SAFETY Page 1 1 Section 1 SAFETY...

Page 18: ...053257 01 2014 SECTION 1 SAFETY Page 1 2 State Regulations Proposition 65 Warning...

Page 19: ...053257 01 2014 SECTION 1 SAFETY Page 1 3 Federal Regulations Respiratory Hazards...

Page 33: ...053257 01 2014 SECTION 2 OPERATIONS Page 2 1 Section 2 OPERATIONS...

Page 41: ...053257 01 2014 SECTION 3 SERVICE Page 3 1 Section 3 SERVICE...

Page 53: ...053257 01 2014 SECTION 3 SERVICE Page 3 13...

Page 59: ...053257 01 2014 SECTION 4 PARTS Page 4 1 Section 4 PARTS...

Page 104: ...053257 01 2014 SECTION 4 PARTS Page 4 46 Electrical Schematic Illustration...

Page 105: ...053257 01 2014 SECTION 4 PARTS Page 4 47 Electrical Schematic Illustration...

Page 106: ...053257 01 2014 SECTION 4 PARTS Page 4 48 Hydraulic Schematic Illustration...

Page 119: ...053257 01 2014 INTENTIONALLY BLANK...