3-18

Installing A ControlNet Cable System

Publication 1786-6.2.1 - April 1998

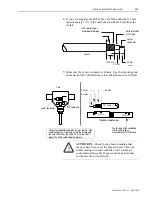

Connecting Cable Sections

Connect the cable sections to the tap’s BNC connectors.

Terminating Segments

The taps on the ends of the segment have only one cable connector

attached to them. This leaves an open, or unterminated, end on the

segment. Signals transmitted along the cable will reflect off these

unterminated ends and interfere with transmission.

To eliminate signal reflections from the ends of the segment,

you must attach a 75

Ω

terminator to the first and last taps on the

segment. The terms “first” and “last” refer to the physical location of

the node along the trunk cable.

1.

Connect one end of the trunk-cable section to one of the tap’s

BNC connectors.

2.

Install a 75

Ω

terminator onto the tap’s other BNC connector.

20078

20078

Repeat steps 1 and 2 at the other

end of the segment

20079

1786-XT