13

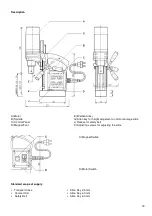

Switching on and off

•

Check connecting line and plug on damages first!

•

Push button MAGNET ON, in order to initiate the magnet and the magnetic adhesion is guaranteed.

•

For non-magnetizable materials, please use the ROTABEST Vacubest (Prod.-No. 18150).

•

When working on walls and ceilings, safe the machine with the safety belt.

For these operations we recommend cooling with our spray ALFRA BIO 2000, Prod.-No. 21010.

•

Push the button MOTOR ON to start the Motor.

•

The magnet foot now reaches its maximum magnetic adhesion! In case of a damaged magnet,

the motor won´t start.

•

To switch off machine proceed in reverse order: MOTOR OFF and then MAGNET OFF!

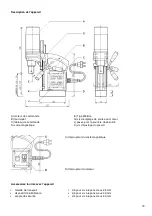

How to work with annular cutters

•

Push ejector pin (center pin) through head of annular cutter.

•

Core drills with Weldon shank are tightened with clamping screws DIN 913 on both clamping surfaces.

•

Core drills with RotaQuick shank are tightened with clamping screws DIN 914 in a countersinking, tighten the

second clamp screw

.

•

First place annular cutter with ejector pin on a marked center or marking.

•

Spot-drill until the entire cut edge is formed as a circle.

Drilling with ALFRA ROTABEST cutters does not require much expenditure of force.

•

During the drilling process the cutter should be cooled permanently. Optimal Cooling is possible by

internal cooling with our coolant unit.