Operation and Configuration

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

23

6.14.2

Loop Break Alarm

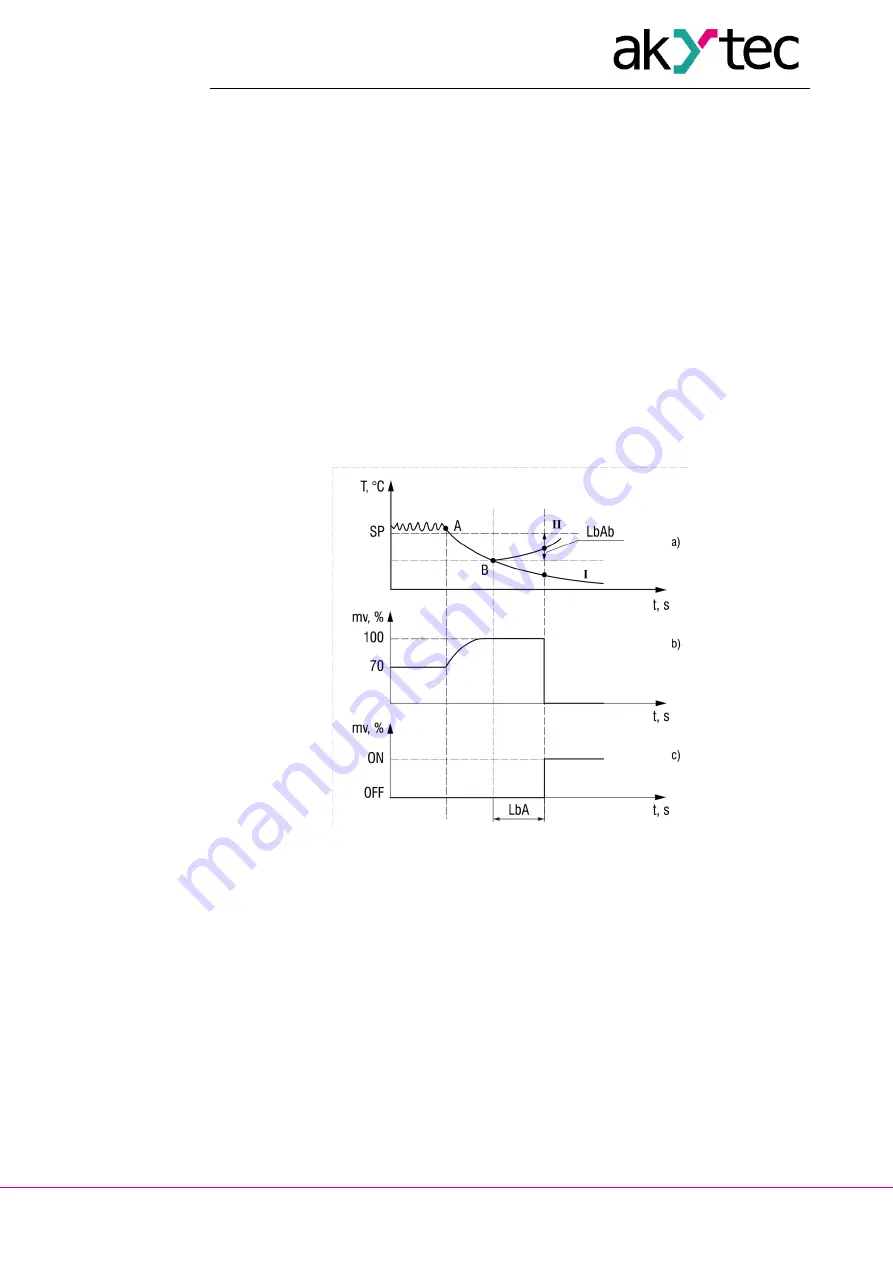

The control loop break occurs and Loop Break Alarm (LBA) is activated, if the maximum

or minimum output signal is generated, but the process value remains unchanged within

the specified time. Once LBA has been activated, the control process will be stopped, the

alarm output activated and the

LBA

indicator flashes on.

The function is defined by two parameters in

Adv

group (see Fig. 6.12):

LbA

– LBA Time

LbAb

– LBA Range

Point A – the heater fails and the temperature goes down (Fig. 6.12

а), the output

signal

increases and the deviation grows (Fig. 6.12b)

Point B – the temperature keeps going down and the output signal reaches 100%, LBA

Time countdown begins

Curve I – if the LBA Time is exceeded and the temperature keeps going down, the alarm

is activated (Fig. 6.12c)

Curve II – if the process value starts growing, but the variation does not reach the LBA

Range within the LBA Time, the alarm is activated as well (Fig. 6.12c)

Fig 6.12

LBA Time is measured in seconds and can be determined as follows:

–

set the output signal to maximum

–

measure the time it takes the process value to change by the LBA Range value (10

by default)

–

double the measured value and set the result as the LBA Time

If

LbA

= 0, the LBA function is deactivated and

LbAb

not available.

LBA Range should be set in measuring units within the range 0.0…999.9 for the tempera-

ture sensors (RTD or TC) and within the range 0…9999 for the linear signals.

6.14.3

Safe state

In case of an error or LBA the control will be stopped and

–

in case of the on-off control Output 1 will be set to the level specified in the parameter

onEr

(On-off safe state)