7

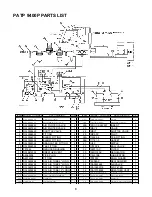

PATP HT Hose Tube Assembly 5524903

1

2

ITEM

PART NO.

PART NAME

QTY

1

2999929

HYD HOSE ASSY 10000

2

2

5525236

PATP TUBE ASM W/ SLEEVE

1

HYD HOSE ASSY 10000 REPLACEMENT HYD FITTINGS

ITEM

PART NO.

PART NAME

QTY

1

2900094

10,000 PSI NIPPLE

1

2

2900095

10,000 PSI COUPLING

1

PATP TUBE ASM REPLACEMENT PARTS

ITEM

PART NO.

PART NAME

QTY

1

2999071

PATP 7 CONDUIT

16.4'

2

2999072

PATP CONDUIT CONNECTOR

2

3

2999073

PATP 8 I CON INSERT

6

4

2999074

PATP 9 PU3 TUBING

49.2'

5

2990300

A 100 59 SLEVE

12'

6

1715741

PG5 BAND

2

CAUTION: Avoid damaging hydraulic hose.

Avoid sharp bends and kinks when routing hy-

draulic hoses. Using a bent or kinked hose will

cause severe back-pressure. Sharp bends and kinks will

internally damage the hose leading to premature hose

failure.

IMPORTANT:

Do not lift hydraulic equip-

ment by the hoses or swivel couplers. Use

the carrying handle or other means of safe

transport.

WARNING: Only use hydraulic cylinders in a

coupled system.

Never use a cylinder with un-

connected couplers. If the cylinder becomes ex-

tremely overloaded, components can fail catastrophically

causing severe personal injury.

Do not drop heavy objects on hose.

A

sharp impact may cause internal damage

to hose wire strands. Applying pressure to

a damaged hose may cause it to rupture.

Summary of Contents for PATP-9400-P

Page 9: ...9...

Page 10: ...10...

Page 11: ...11...

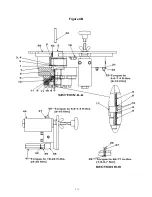

Page 12: ...12 Figure 2...

Page 13: ...13 Figure 3...

Page 14: ...14 Figure 4B...

Page 15: ...15 Figure 4A...

Page 16: ...16 Figure 5...

Page 17: ...17 Figure 6...

Page 18: ......

Page 19: ......