3

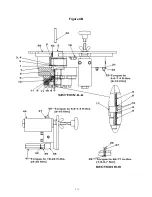

Vent Plug

See Figure 1. Remove the shipping plug from the vent

port and replace it with the vent/fill gauge cap supplied

with the pump. Tighten the vent/fill gauge cap hand tight

only.

Hydraulic Connection

2. Connect one end of the hose tube assembly to the

pump connections and the other to the tube puller ram.

Connect the pneumatic control tube to the pendant con-

trol or to the Patp ram. The hydraulic connectors are

push-to-connect and the pneumatic control connections

are keyed with threaded retaining ring (Hand TIght Only).

Air Connection

This pump requires 100 psi air at 40 scfm. A regulator

filter lubricator has been installed on the pump to aid in

providing clean lubricated air. and to allow for air pres-

sure adjustment. Attach incoming air supply to 3/4 NPT

port on air valve with thread sealant.

INSTALLATION

Oil Level

Check the oil level of the pump prior to start-up and add

Enerpac hydraulic oil, if necessary, by removing the vent/

fill gauge cap (See Figure 1). When the gauge needle

points to the end of the green zone the reservoir is full.

CAUTION:

Add oil only when all system components are

in the retract position, or the system will contain more oil

than the reservoir can hold.

OPERATION

1. Check oil level of the pump and add oil if necessary.

See Oil Level instructions.

CAUTION:

During system operation, the oil level should

never fall below the yellow zone or pump damage may

occur.

2. Make sure that the pump reservoir is vented (Vent/Fill

Gauge Cap is installed.)

CAUTION:

Reservoir must be vented whenever pump is

running. Failure to vent the pump will cause cavitation

and pump damage.

3. To start the pump, press the trigger on the PATP ram

or the pendant button if using the HDP, HDQ, or RAV

ram. The ram will advance as long as the button is held

down.

4. Release the button to retract the ram. The motor will

remain on.

5. Press the red OFF button on the pump to stop the pump

motor. With the motor off, both hoses are de-

pressurized.Oil from the retract line will return to tank.

Pressure Adjustment

Pressure is factory preset and should not require adjust-

ment.

PATP 9400 P Pump Specifications:

Air Requirement for maximum Pressure

100 PSI @ 40 SCFM

@ 50 PSI (3.5 bar)

850 in

3

/min (13.9 1/min)

Hydraulic Flow

@ 1000 (69bar)

105 in

3

/min (1.72 1/min)

@ 10000 PSI (690 bar) 30 in

3

/min (0.5 1/min)

External Relief Valve Adjustment

1100 10000 PSI

(69-690 bar)

Sound Pressure Level

80-85 dBA

Reservoir Capacity

2 Gallon

(7.57 Liters)

Dimensions:

Over All Length

30 inches

(762 mm)

Height

29 1/2 Inches

(749 mm)

Width

19 3/4 Inches

(502 mm)

Weight

160 Lbs.

(72.7 Kilo.)

Vent/Fill/Gauge Cap

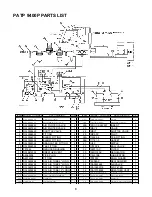

Summary of Contents for PATP-9400-P

Page 9: ...9...

Page 10: ...10...

Page 11: ...11...

Page 12: ...12 Figure 2...

Page 13: ...13 Figure 3...

Page 14: ...14 Figure 4B...

Page 15: ...15 Figure 4A...

Page 16: ...16 Figure 5...

Page 17: ...17 Figure 6...

Page 18: ......

Page 19: ......