6

12. Route air line along frame from the inflation valve location to the

air springs (Figure 9). Use the provided clips and self tapping

screws to attach to the outside of the frame rail and the air line

sleeves to protect the air line when routing through existing holes

in the frame. It is not necessary to drill a hole for this type of

self tapping screw. Simply drive the screw through the frame

section. Attach air line to chassis with the provided plastic straps

where possible.

CAUTION: To prevent the air line from melting, keep it at least

12 " from the exhaust system.

13. Cut off excess air line squarely. Install the air line into the fitting.

This is a push to connect fitting. Push and slightly turn the cut

end of the air line into the fitting as far as it will go. There is a

definite “click” that can be heard and or felt when the air line is

seated. The air line should go in

9

/

16

". It is now installed.

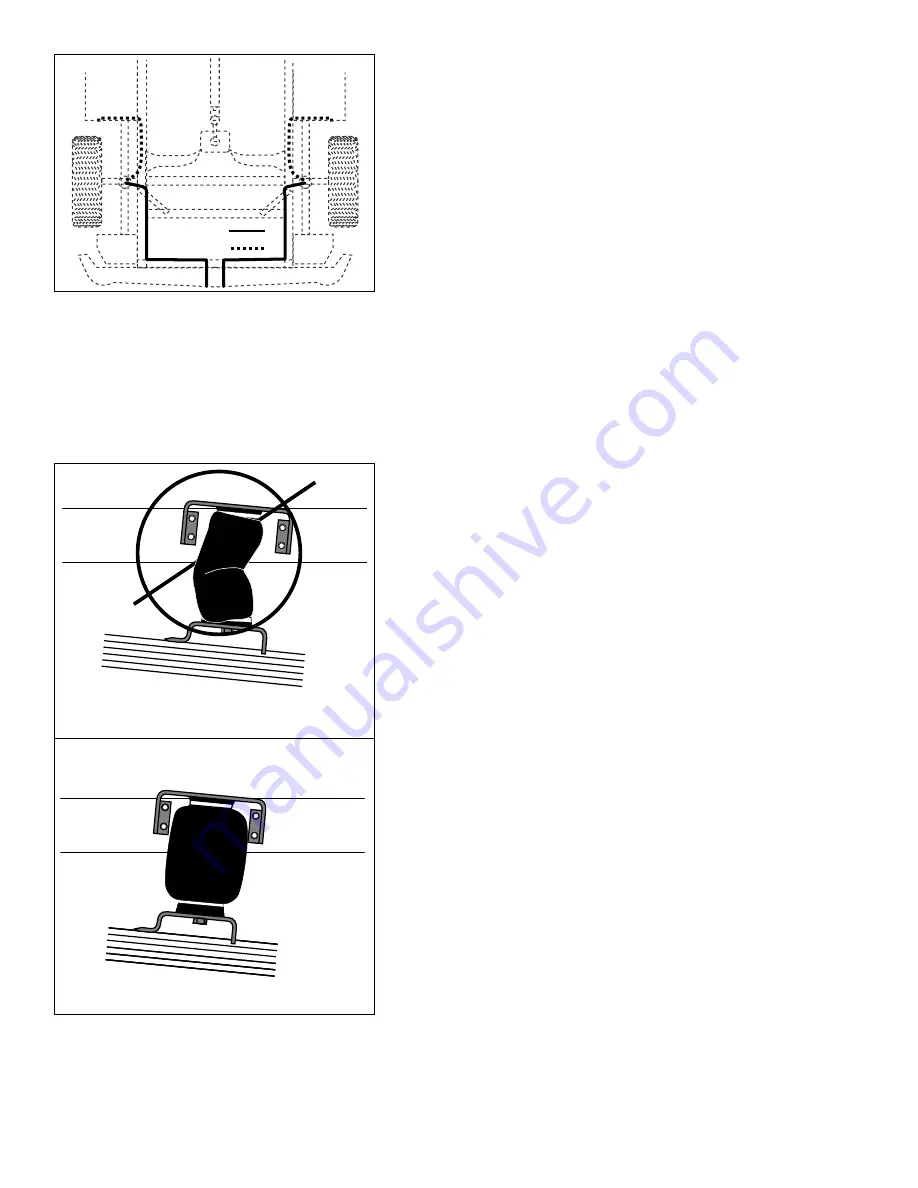

14. VERY IMPORTANT: With the bottom and top of the air spring

still loose, inflate the air spring to approximately 10 p.s.i. By

using the slotted adjustment in the lower bracket align the air

spring so that there is a symmetrical cushion of air around the

lower base. This can be accomplished by pressing all around

the air spring to feel an air gap between rubber and piston. Adjust

by tapping it inboard or outboard for proper alignment (Figure

10).

15. Tighten the lower end by holding the Bolt with a 1

1

/

6

" wrench

and turning the air spring by hand. Use no tools, hand tight is

sufficient. It may be necessary to let some of the air out of the

air spring in order to turn it.

16. If L-bracket was used for the lower bracket to hook over, then

retighten U-bolts to 115 ft–lbs. Tighten lower bracket U-bolts to

16 ft–lbs.

17. Now tighten the upper nylon nut (4 ft–lbs). Do not overtighten.

18. Inflate to 30 p.s.i. Check all fittings and inflation valve core for

leaks with a liquid solution of

1

/

5

dish soap to

4

/

5

water. Check

once again to be sure you have clearance all around the air

spring at its fully inflated diameter (4.6").

19. Recheck air pressure after 24 hours. A 2 – 4 p.s.i. loss after

initial installation is normal. If pressure has dropped more than

5 p.s.i. retest for leaks with soapy/water solution. Please read

and follow the Maintenance and Operating tips. Check to see

that the sleeve rolls back down over the bottom piston after the

vehicle is lowered (Figure 10).

Option 1

Option 2

Figure 9

Not correct: Misaligned or not inflated

(acceptable during assembly)

Correct finished installation: inflated

Figure 10