Single Speed Models

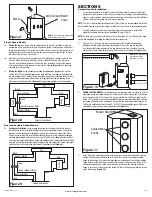

2a.

Wiring the Fan:

Run wiring from an approved wall switch (not included) carrying the

appropriate rating. One neutral (white), one ground (green or bare copper), and one hot

(black lead connected to the switch). Secure the electrical wires to the housing with an

approved electrical connector. Make sure you leave enough wiring in the box to make

the connection to the fan’s receptacle.

2b. From where you have chosen to access the fan’s junction box, connect the white wire

from the house to the white wire from the fan’s receptacle. Connect the black wire

from the wall switch to the black wire from the fan’s receptacle. Connect the ground

wire from the house to the green wire from the fan housing

(Figure 8).

Use approved

methods for all connections.

2c.

Wiring the Lights:

Using a properly grounded standard duplex toggle switch (such as

Leviton 5224-2W, not included) connect the black wire from the supply to one side of the

top and bottom switch. Connect the red wire (light) from the fan housing to the other side

of the top switch and connect the purple wire (night light) from the fan housing to the

other side of the bottom switch.

(Figure 8).

Use approved methods for all connections.

Dual and Variable Speed Models

3a.

Continuous Ventilation:

For two speed fans wired for continuous ventilation, connect

the White wire of the fan to the White (Neutral) wire from the power source. Connect the

ground wire from the house to the green wire from the fan housing. Connect the Black

wire of the fan to the Black wire (Hot) from the power source. Using a properly grounded

standard duplex toggle switch (such as Leviton 5224-2W, not included) connect the Black

wire from the supply to one side of the top and bottom switch. Connect the Red wire (light)

from the fan housing to the other side of the top switch and connect the Purple wire (night

light) from the fan housing to the other side of the bottom switch

(Figure 9).

www.airkinglimited.com

6728056 Rev. C 5-14

3 of 12

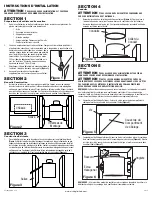

SECTION 6

Completing the Installation

1.

Use a sealant appropriate for contact with the building materials present and for the

temperature requirements of the installation to prevent air leakage from unconditioned

spaces is recommended. If gaps between unit housing and ceiling are great, additional

material (backing rod, ceiling material) may be required.

NOTE:

This fan is rated for direct insulation contact (Type IC) and it is recommended that this fan

be completely covered by insulation in order to reduce heat loss or gain to unconditioned space.

2.

If the fan’s blower assembly was removed during the wiring process, reinstall the

blower by reversing the directions in

Section 5

(Wiring),

Step 1b.

NOTE:

An extra 2-pin connector with tape over it may be present. This is utilized for the boost

speed. See

Section 9

(Activating the Boost Speed) for more details.

3.

Plug the fan’s 2 pin and 3 pin quick connect motor cords into the corresponding

receptacle located on the wire compartment cover. Connect the two pin connector

from the humidistat compartment to the two pin connector from the side of the wire

compartment cover. These cords will only fit one way into the receptacles

(Figure 10).

4.

VARIABLE SPEED MODELS:

First decide if you will require more or less than 65 CFM of

ventilation on the low speed setting. If it is less than 65 CFM place the Low CFM Range

rocker switch on the 30-60 range. If it is more, place the low CFM range rocker switch

on the 70-120 range. Once you have decided on the minimum required airflow, the fans

low speed CFM level can be adjusted by using either the lower adjustment knob (30-60

CFM) or the middle adjustment knob (70-120 CFM). The desired high speed CFM can be

adjusted by using the upper most adjustment knob

(Figure 11).

5.

Install the ceiling mounting flange to cover any gaps which exist between the housing

and the finished ceiling. Remove the two screws that connect the ceiling mounting

flange to the housing. Put sealant (not provided) on inside edge of the ceiling mounting

flange to ensure that the flange is sealed to the ceiling. Line up the screw holes in the

ceiling mounting flange with the screw holes on the inside of the housing and press

flange in place so it is tight against the ceiling. Reinstall ceiling flange mounting screws

inside the housing

(Figure 12)

.

Screw

Wire Compartment

Cover

Figure 7

NOTE:

Wire compartment configuration

will be dependent on model.

Figure 8

Supply from house

Black

Neutral (White)

Ground (Green or Bare)

Fan

Black

Neutral (White)

Green

Switch

Black

Purple

Red

Switch

Figure 9

Supply from house

Black

Neutral (White)

Ground (Green or Bare)

Fan

Black

Neutral (White)

Green

Switch

Black

Purple

Red

Figure 10

NOTE:

Wire compartment

configuration will be

dependent on model.

30

40

50

60

LO

W

LO

W

HI

GH

70

90

10

0

120

80

11

0

13

0

Bo

ost

Figure 11

Adjustment

Knobs

Rocker Switch