www.airkinglimited.com

9842 Rev A. 9-05

2 of 8

INSTALLATION INSTRUCTIONS

CAUTION:

MAKE SURE POWER IS SWITCHED OFF AT

SERVICE PANEL BEFORE STARTING INSTALLATION.

SECTION 1

Installation Requirements

1.

Electrical Requirements:

This unit requires a grounded electrical

supply line of 120 volts AC, 60 Hz, 15 amp circuit.

WARNING:

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR PERSONAL INJURY, PROPERLY INSTALL TO AN OUTLET BOX

MARKED “ACCEPTABLE FOR FAN SUPPORT”. USE SCREWS

PROVIDED WITH OUTLET BOX. MOST OUTLET BOXES COMMONLY

USED FOR THE SUPPORT OF LIGHTING FIXTURES ARE NOT

ACCEPTABLE FOR FAN SUPPORT AND MAY NEED TO BE REPLACED.

CONSULT A QUALIFIED ELECTRICIAN IF IN DOUBT.

2.

Electrical Box:

This unit will fit any of the following electrical

boxes: 4" octagon box, 3" octagon box, 1/2" deep ceiling pan, or

a plaster ring with 3-1/2" mounting hole centers mounted on one

of the above listed boxes. This fan will also install on a “Wiremold”

No. 5738 fixture box. The electrical box must be securely anchored

and capable of withstanding a load of at least 35 pounds.

CAUTION:

IF ONE OF THE ABOVE ELECTRICAL BOXES IS

NOT PRESENT FOR PROPER INSTALLATION, CONTACT A LICENSED

ELECTRICIAN.

SECTION 2

Preparing the Ceiling Fan

1.

Unpack fan from the carton and confirm that all pieces are

present. The following should be present:

1 -Motor assembly

4 - Blades

4 - Blade mounting brackets

1 - Hanger bracket

1 - Canopy

1 -Package containing:

12 - 1/2" washer head screws

12 - paper washers

1 - pull cord

2 - 8-32 machine screws

1 -Instruction/Safety Sheet

NOTE:

Extra hardware is included in parts bag.

2.

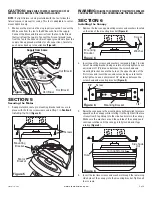

Install mounting bracket to the electrical box marked “Acceptable

For Fan Support” using the screws provided with the outlet box.

If no screws are present, use the provided 8-32 machine screws.

Insert the screws through the slotted holes in the bracket and

attach to the electrical box. Tighten both screws to the electrical

box

(Figure 1)

.

CAUTION:

IF BRACKET AND/OR ELECTRICAL BOX ARE NOT

SECURELY ATTACHED, THE FAN COULD WOBBLE.

SECTION 3

Installing the Fan

1. Remove and save the two screws on the bottom of the mounting

bracket and the one screw on motor assembly bar

(Figure 2)

.

2. Hang motor assembly from mounting bracket by inserting indented

side into square hole in mounting bracket

(Figure 3)

.

SECTION 4

Wiring

CAUTION:

ALL ELECTRICAL CONNECTIONS MUST BE MADE

IN ACCORDANCE WITH LOCAL CODES, ORDINANCES, OR NATIONAL

ELECTRICAL CODE. IF YOU ARE UNFAMILIAR WITH METHODS OF

INSTALLING ELECTRICAL WIRING, SECURE THE SERVICES OF A

QUALIFIED ELECTRICIAN.

Screw

Electrical Box

Mounting

Bracket

Figure 1

Mounting

Bracket

Figure 3

Screw

Figure 2

Screws

Hole

Motor

Assembly