45

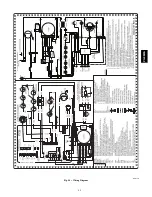

15. Refer to furnace wiring diagram, and connect thermostat

leads if previously disconnected.

16. To check blower for proper rotation:

a. Turn on electrical supply.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury, or death.

Blower access door switch opens 115--v power to

furnace control. No component operation can occur

unless switch is closed. Exercise caution to avoid

electrical shock from exposed electrical components

when manually closing this switch for service purposes.

!

WARNING

b. Manually close blower access door switch.

NOTE

: If thermostat terminals are jumpered at the time blower

access door switch is closed, blower will run for 90 sec before

beginning a heating or cooling cycle.

c. Perform component self--test as shown at the bottom of

the SERVICE label, located on the front of blower access

door.

d. Verify blower is rotating in the correct direction.

17. If furnace is operating properly, RELEASE BLOWER

ACCESS DOOR SWITCH. Remove any jumpers or re-

connect any disconnected thermostat leads. Replace

blower access door.

18. Downflow or horizontal furnaces with vent pipe through

furnace only:

a. Install and connect short piece of vent pipe inside furnace

to existing vent.

b. Connect vent connector to vent elbow.

19. Reinstall outer door.

20. Cycle furnace through one complete heating and cooling

cycle. Verify the furnace temperature rise as shown in

“Adjustments” Section. Adjust temperature rise as shown

in “Adjustments” Section. If outdoor temperature is below

70

_

F, (21

_

C) turn off circuit breaker to outdoor unit be-

fore running furnace in the cooling cycle. Turn outdoor

circuit breaker on after completing cooling cycle.

CLEANING HEAT EXCHANGER

The following steps should be performed by a qualified

service agency:

NOTE

: If the heat exchangers get a heavy accumulation of soot

and carbon, they should be replaced rather than trying to clean

them thoroughly. A heavy build--up of soot and carbon indicates

that a problem exists which needs to be corrected, such as

improper adjustment of manifold pressure, insufficient or poor

quality combustion air, incorrect size or damaged manifold

orifice( s), improper gas, or a restricted heat exchanger. Action

must be taken to correct the problem.

If it becomes necessary to clean the heat exchangers because of

dust or corrosion, proceed as follows:

1. Turn OFF gas and electrical power to furnace.

2. Remove outer access door.

3. Disconnect vent connector from furnace vent elbow.

4. For downflow or horizontal furnace having an internal

vent pipe, remove internal vent pipe within the casing.

5. Disconnect wires to the following components. Mark

wires to aid in reconnection of (be careful when discon-

necting wires from switches because damage may occur):

a. Draft safeguard switch.

b. Inducer motor.

c. Pressure switch(es).

d. Limit over--temperature switch.

e. Gas valve.

f. Hot surface igniter.

g. Flame--sensing electrode.

h. Flame rollout switches.

6. Remove screws that fasten the collector box assembly to

the cell panel. Be careful not to damage the collector box.

Inducer assembly and elbow need not be removed from

collector box.

7. Disconnect gas line from gas manifold.

8. Remove the 5 screws that attach the burner assembly to

the cell panel. The gas valve and individual burners need

not be removed from support assembly. Remove NOx

baffles if installed.

NOTE

: Be very careful when removing burner assembly to

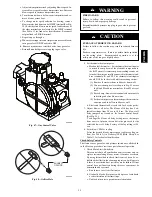

avoid breaking igniter. See Fig. 51 and 52 for correct igniter

location.

9. Using field--provided 25--caliber rifle cleaning brush,

36--in. (914 mm) long, 1/4” (6 mm) diameter steel spring

cable, a variable speed, reversible electric drill, and vacu-

um cleaner, clean cells as follows:

a. Remove metal screw fitting from wire brush to allow in-

sertion into cable.

b. Insert the twisted wire end of brush into end of spring

cable, and crimp tight with crimping tool or crimp by

striking with ball--peen hammer. TIGHTNESS IS VERY

IMPORTANT.

9/32”

7.1mm

5/16”

7.9mm

A05025

Fig. 51 -- Igniter Position--Side View

1-7/8

47.6 mm

A05026

Fig. 52 -- Igniter Position--Top View

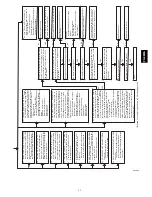

PG

8M

EA

Summary of Contents for PG8JEA

Page 4: ...4 A10269 Fig 2 Clearances to Combustibles PG8MEA ...

Page 28: ...28 A10133 Fig 33 Chimney Inspection Chart PG8MEA ...

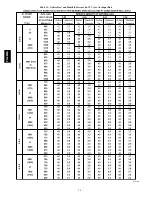

Page 38: ...38 Table 13 Orifice Size and Manifold Pressure In W C for Gas Input Rate A10180 PG8MEA ...

Page 39: ...39 Table 13 Orifice Size and Manifold Pressure In W C for Gas Input Rate CONT A10180A PG8MEA ...

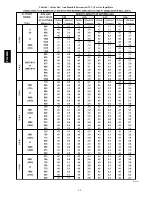

Page 40: ...40 Table 14 Orifice Size And Manifold Pressure In W C For Gas Input Rate A10181 PG8MEA ...

Page 41: ...41 Table 14 Orifice Size And Manifold Pressure In W C For Gas Input Rate CONT A10181A PG8MEA ...