9

●

TO ADJUST DEPTH OF CUT-

DISCONNECT TOOL

FROM POWER SOURCE.

Adjust the depth of cut as desired. A depth scale is provided.

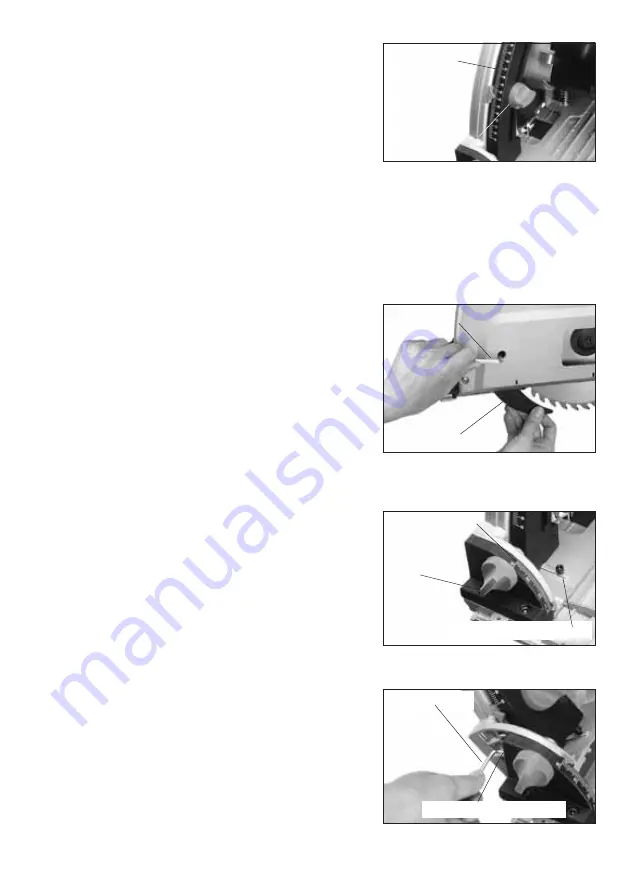

To adjust the depth of cut:

Loosen the depth lock knob about 1-1/2 turns. While pushing in

slightly, slide the depth stop up or down as desired and retighten.

See fig.5

Riving knife

This machine is fitted with a riving knife as standard. This design helps to resist kickback. For safety reasons, all

saw work should always be carried out with the riving knife installed and correctly set.

The riving knife must be set so that the distance between riving knife and cutting circle of the saw blade is

2 to 4 mm (not more than 5mm) and the rim of the blade does not extend more than 5 mm beyond the lowest edge

of the riving knife.

Setting the riving knife:

1.

Unplug the machine.

2.

Lock the saw in its blade change position for setting the riving

knife. At this position the locking bolt will line up with the port

in the cover.

3.

Loosen the locking bolt about a half turn with the hex wrench

supplied.

4.

Set the riving knife correctly, and retighten the locking bolt.

Double check the adjustment, as it is spring loaded and can

shift when being tightened. See fig.6

●

TO ADJUST BEVEL ANGLE -

DISCONNECT TOOL FROM

POWER SOURCE.

To adjust the bevel angle, refer to the bevel gauge on the base. There

are markings for different angles from 0 to 45 degrees.

To adjust the bevel angle:

Loosen both of the bevel lock knobs (See fig.7) front and rear about

a half turn, then rotate the base to the desired angle. Retighten both

bevel lock knobs to hold at the desired position.

●

TO ZERO IN THE BEVEL ANGLE -

DISCONNECT TOOL

FROM POWER SOURCE.

The bevel angles are properly set at the factory, but if the

adjustments are disturbed, there is provision for zeroing in both the

45 degree and 0 degree bevel positions. To zero the 45 degree

position, (See fig.8) using a properly sized allen hex wrench, adjust

the small set screw on the right side of the front bevel block. To

adjust the 0 degree bevel position adjust the 2 vertical socket head

screws on the base (See fig.1) located adjacent to the bevel adjustor

knobs. Check the accuracy of the angles with a suitable measuring

tool.

Fig.5

Fig.6

Depth scale

Depth lock stop

Riving knife

Hex wrench

Fig.7

Bevel scale

Bevel lock

knob

0 degree bevel positions

Fig.8

45 degree bevel positions

Hex wrench