a) Two pressure test points are provided, for

measuring inlet and outlet pressures. These are

G & H on Figure 4. For convenience, a further

outlet pressure test point is provided in outlet

immediately below the control valve.

b) Pressure adjusting screw (REG.ADJ)

c) Pilot adjusting screw (PILOT ADJ). This screw is

provided on control for adjusting flow of gas to pilot

burner. The appliance is designed to operate on

full gas flow to pilot. Therefore, to ensure that full

flow is available, turn screw fully clockwise then

back 2 complete turns.

d) A screw marked NO PR. This is for rendering

inbuilt governor (i.e. pressure regulator)

inoperative, and is turned when propane is being

used. This screw must not be tampered with as its

required position will have been determined at

works.

e) A screw marked 1 STEP ADJ.

This is a device enabling the gas supply to the burner

to flow at reduced rate initially, automatically

increasing to full rate after a brief time interval.

This assists in effecting smooth ignition of the gas.

This adjustment has been correctly set at works but

should further adjustment be considered necessary,

proceed as follows:

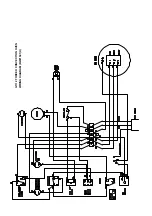

Figure 4

2.5.5 Natural Gas Models Only

a) Adjust pressure regulator to give correct outlet

pressure of 15mbar.

b) Light oven and allow to heat up to about 150

o

C.

Then turn thermostat knob to a low setting,

shutting off burner.

c) Remove plastic cover over 1 step adjuster screw

and turn screw fully clockwise.

d) Tentatively turn screw anti-clockwise and check

ignition performance by moving thermostat knob to

a high setting.

e) Once minimum flow which ensures slow and

smooth ignition has been determined, replace

plastic cover over adjusting screw.

2.5.6 Propane Models Only

a) Remove plastic cap and turn screw NO PR fully

clockwise.

b) Adjust pressure regulator until a pressure of about

12mbar is obtained on outlet.

c) Repeat (b) to (d) as above.

d) Turn to NO PR screw fully anti-clockwise.

e) Adjust pilot adjustment screw if necessary.

Note

On no account must the NO PR screw be in an

intermediate position, i.e. it must be fully clockwise for

natural gas, or fully anti-clockwise for Propane.

2.6 INSTRUCTION TO USER

Important

After installing and commissioning appliance, hand

User Instructions to user or purchaser and ensure the

instructions for lighting, turning off, correct use and

cleaning are properly understood. The location of gas

isolating cock and electrical supply switch should be

made known to user and the procedure for that

operation in an emergency demonstrated.

SECTION 3 - SERVICING and

CONVERSION

Important

BEFORE ATTEMPTING ANY SERVICING ENSURE

THAT THE ISOLATING COCK IS TURNED OFF

AND THAT IT CANNOT BE INADVERTENTLY

TURNED BACK ON.

AFTER ANY MAINTENANCE TASK, CHECK THE

APPLIANCE TO ENSURE THAT IT PERFORMS

CORRECTLY AND CARRY OUT ANY NECESSARY

ADJUSTMENTS AS DETAILED IN SECTION 1

After carrying out any servicing or exchange of gas

carrying components -

ALWAYS CHECK FOR GAS SOUNDNESS!

3.1 GAS CONVERSION CHECK LIST

For conversion to NATURAL GAS, add the correct

governor and set the burner pressure.

For conversion to PROPANE GAS, replace the

NATURAL burner with a PROPANE burner. Remove

the governor from the gas circuit.

Other considerations -

CHANGE INJECTORS

CHANGE BYPASS SCREW AND SET LOW RATE

CHANGE DATA PLATE

3.2 REMOVAL OF PANELS and COMPONENTS

3.2.1 Oven Control Panel

Access to various electrical controls, terminals etc,

also piezo igniter, is gained upon withdrawal of the

panel. Remove the fixings which secure the panel

and draw it forward.