4

Air Coil Nailer

Http://www.aeroprotools.com

Fig 3

caused to the head or to the body in the event of possible recoil consequent upon a disruption in the energy supply

or hard areas within the workplace.

(

see fig 2

)

Never actuate the fastener driving tool into free space. This will avoid any hazard caused by

free flying fasteners and excessive strain of the tool.

The tool shall be disconnected from the compressed air system for the purpose of

transportation, especially where ladders are used or where an unusual physical posture is

adopted whilst moving(see Fig 3).

Carry the fastener driving tool at the workplace using only the handle, and never with the

trigger actuated.

Take conditions at the workplace into account. Fasteners can penetrate thin work pieces or slip off corners and

edges of workplaces, and thus put people at risk.

For personal safety, use protective equipment such ad hearing and eye protection (see fig 2)

IMPORTANT: DO NOT

direct the adjustable vent hole to the operator or other person or animals during the use.

2.6 Triggering devices

Fastener driving tools are operated by actuating the trigger using finger pressure.

In addition, fastener driving tool is fitted with a safety yoke which enables the driving operation to be carried out

only after the muzzle of the tool is pressed against a work piece, These tool are marked with an inverted

triangle( ) behind the serial number and are not permitted for use without an effective safety yoke.

2.7 Actuating systems

Depending on their purpose, fastener driving tool is fitted with single sequential actuating system and contact

actuation system.

You could switch to one nail figure to choose single sequential actuation, and switch to two nail figure to choose

contact actuation.

Fastener driving tools with a safety yoke. See 2.6

- Single sequential actuation: An actuating system in which the trigger and the safety yoke have to be activated so

the only one single driving operation is actuated via the trigger after the muzzle of the tool has been applied to the

driving location, Thereafter further driving operations can only be performed after the trigger has been returned to

the non driving position whilst the safety yoke remains depressed.

-Contact actuation (restricted version):An actuating system in which the trigger and the safety yoke have to be

actuated for each driving operation, with the order of actuation not being specified .For repeated driving operations,

it is sufficient if either the trigger remains activated and the safety yoke is activated thereafter, or vice versa.

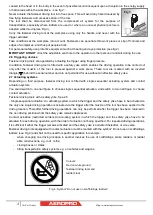

Fastener driving tools equipped with contact actuation must be marked with the symbol” Do not use on scaffoldings,

ladders’ (see Fig.4) and shall not be used for specific application for example:

-

when changing one driving location to another involves the use of scaffoldings, stairs, ladders, or ladder

alike constructions, e.g. roof laths;

-

closing boxes or crates;

-

fitting transportation safety systems e.g. on vehicles and wagons.

Colours:

Red on white ground,

fastener driving tools and

ladder black

Fig. 4: Symbo

l” Do not use on scaffoldings, ladders”

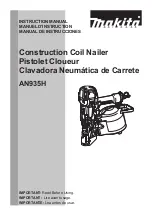

Summary of Contents for MCN55

Page 8: ......