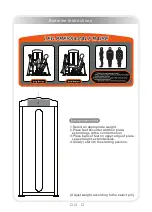

Maintenance Schedule

Your equipment comes with a commercial maintenance decal. For personal,

in home use, please follow the home maintenance schedule listed above.

ROUTINE

COMMERCIAL

MAINTENANCE

HOME

MAINTENANCE

Inspect;

Links, Pull Pins, Snap Locks,

Swivels, Weight Stack Pins

DAILY

WEEKLY

Clean;

Upholstery

DAILY

WEEKLY

Inspect;

Cables or Belts and their tension

DAILY

WEEKLY

Inspect;

Accessory Bars, and Handles

WEEKLY

3 MONTHS

Inspect;

All Decals

WEEKLY

3 MONTHS

Inspect;

All Nuts and Bolts, Tighten if

needed

WEEKLY

3 MONTHS

Inspect;

Anti-Skid Surface

WEEKLY

3 MONTHS

Clean & Lubricate;

Guide Rods with a Teflon (PTFE)

based lubricant (Superlube)

MONTHLY

3 MONTHS

Lubricate;

Seat Sleeves, Turcite Bushings,

Linear Bearing

MONTHLY

3 MONTHS

Clean and Wax;

All Glossy Finishes

6 MONTHS

YEARLY

Repack with Grease;

Linear Bearings

6 MONTHS

YEARLY

Replace;

Cables, Belts and Connecting

Parts

YEARLY

3 YEARS

LATEST DATE ENTRY

─

21

─