8

8

■ Press the release button and allow the pusher to push the nails

up to the driving mechanism. The pusher will stop when it rests

against the end of the nail strip.

NOTE:

Do not allow the pusher to snap back into place.

WARNING

Use only the nails recommended for use with this product. The

use of any other nails can result in tool malfunction, leading to

serious injuries.

WARNING

Never load nails with the workpiece contact or trigger activated.

Doing so could result in possible serious personal injury.

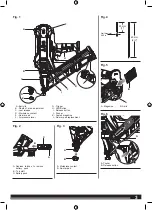

USING THE MODE SELECTOR SWITCH (FOR AFNDA18B

ONLY)

See figures 7 - 8.

WARNING

Never wedge or hold back the workpiece contact mechanism

during operation of the product. Doing so could result in possible

serious injury.

This product is shipped from the factory with the trigger mode

selector set in the single sequential actuation mode. The trigger

mode selector can also be set for contact actuation mode.

Full sequential actuation mode

Full sequential actuation provides the most accurate fastener

placement.

■ Remove the battery pack from the product.

■ Slide the trigger mode selector to (for AFNDA18B only).

■ Reinstall the battery pack.

■ Grip the product firmly to maintain control. Position the nose of

the product onto the work surface.

■ Push the product against the work surface to depress the

workpiece contact.

■ Squeeze the trigger to drive a fastener.

■ Always remove your finger from the trigger after the nail has

been driven.

■ Allow the product to recoil away from the work surface as the

fastener is driven.

NOTE:

The trigger must be depressed within 3 seconds of placing

the nose of the product against the workpiece. If depressing the

trigger does not drive a fastener, lift the product away from the

workpiece, then replace and try driving the fastener again.

Contact actuation mode (for AFNDA18B only)

Contact actuation allows very fast repetitive fastener placement.

■ Remove the battery pack from the product.

■ Slide the trigger mode selector to

.

■ Reinstall the battery pack.

■ Grip the product firmly to maintain control.

■ Squeeze and hold the trigger. Push the product against the work

surface to depress the workpiece contact and drive a fastener.

■ Allow the product to recoil away from the work surface as the

fastener is driven.

NOTE:

In contact actuation mode, the product may also be

operated by depressing the workpiece contact against the surface

and squeezing the trigger. The nose of the product must be pressed

against the workpiece within 3 seconds of depressing the trigger.

If pressing the nose to the workpiece does not drive a fastener,

release the trigger, depress the trigger again, then try driving the

fastener again.

WARNING

During normal use the product will recoil immediately after

driving a fastener. This is a normal function of the product. Do

not attempt to prevent the recoil by holding the nailer against

the work. Restriction to the recoil can result in a second fastener

being driven from the nailer. Grip the handle firmly, let the

product do the work, and do not place second hand on top of

product at any time. Failure to heed this warning can result in

serious personal injury.

WARNING

When used in the contact actuation mode do not carry the

product with the trigger depressed as this will cause a fastener

to discharge if the workpiece contact accidentally bumps against

an object. Failure to observe this warning can result in serious

personal injury.

SETTING THE AIR POWER

See figure 9.

The amount of air power required will depend on the size of the nail

and the workpiece material.

Begin testing the depth of drive by driving a test nail into the same

type of workpiece material used for the actual job.

■ Remove battery pack from the tool.

■ Move power adjustment lever to the right to increase air power

or to the left to decrease air power.

It may be possible to achieve the desired depth with air power

adjustments alone. If finer adjustments are needed, use the depth

of drive adjustment.

DRIVE DEPTH ADJUSTMENT

See figure 10.

The driving depth of the nail may be adjusted by moving the dial to

the left to decrease or right to increase the depth the nail is driven. It

is advisable to test the depth on a scrap workpiece to determine the

required depth for the application and to drive a test nail after each

adjustment until the desired depth is set.

REMOVING NAILS FROM THE PRODUCT

See figure 11.

Remove the battery pack from the product.

WARNING

Remove the battery pack from the product before removing nails.

Failure to do so could result in serious personal injury.

To remove a strip of nails from the product, hold the nailer by the

Summary of Contents for 8904077

Page 1: ......

Page 11: ...11 11 ...