19

:: Tuning Tips

:: Painting Tips

Tips for Beginners:

Before making any changes to the standard setup, make sure you can get around the track without crashing.

Changes to your vehicle will not be beneficial if you can’t stay on the track. Your goal is consistent laps.

Once you can get around the track consistently, start tuning your vehicle. Make only ONE adjustment at a time, testing

it before making another change. If the result of your adjustment is a faster lap, mark the change on the included setup

sheet (make adddtional copies of the sheet before writing on it). If your adjustment results in a slower lap, revert back

to the previous setup and try another change.

When you are satisfied with your vehicle, fill in the setup sheet thoroughly and file it away. Use this as a guide for future

track days or conditions. Peridicaly check all moving suspension parts. Suspension components must be kept clean

and move freely without binding to prevent poor and/or inconsistent handling.

Your B6 Team Kit comes with a clear polycarbonate body. You will need to prep the body before you can paint it.

Wash the INSIDE thoroughly with warm water and liquid detergent (do not use any detergents with scents or added

hand lotion ingredients!). Dry the body using a clean, soft, lint-free cloth. Use the supplied window masks to cover the

windows from the INSIDE of the body (RC cars get painted from the inside). Using high quality masking tape, apply tape

to the inside of the body to create a design. Spray (use either rattle can or airbrush) the paint on the inside of the body

(prefferably dark colors first, lighter colors last).

NOTE: ONLY use paint that is recommended for use with (polycarbonate) plastics. If you do not, you can destroy the

plastic body!!!!.

After the paint has completely dried (usually after 24 hours), cut the body along the trim lines. Make sure to drill or use

a body reamer to make the holes for the antenna if needed! Use hook and loop tape to secure the body to the side rails

of the vehicle.

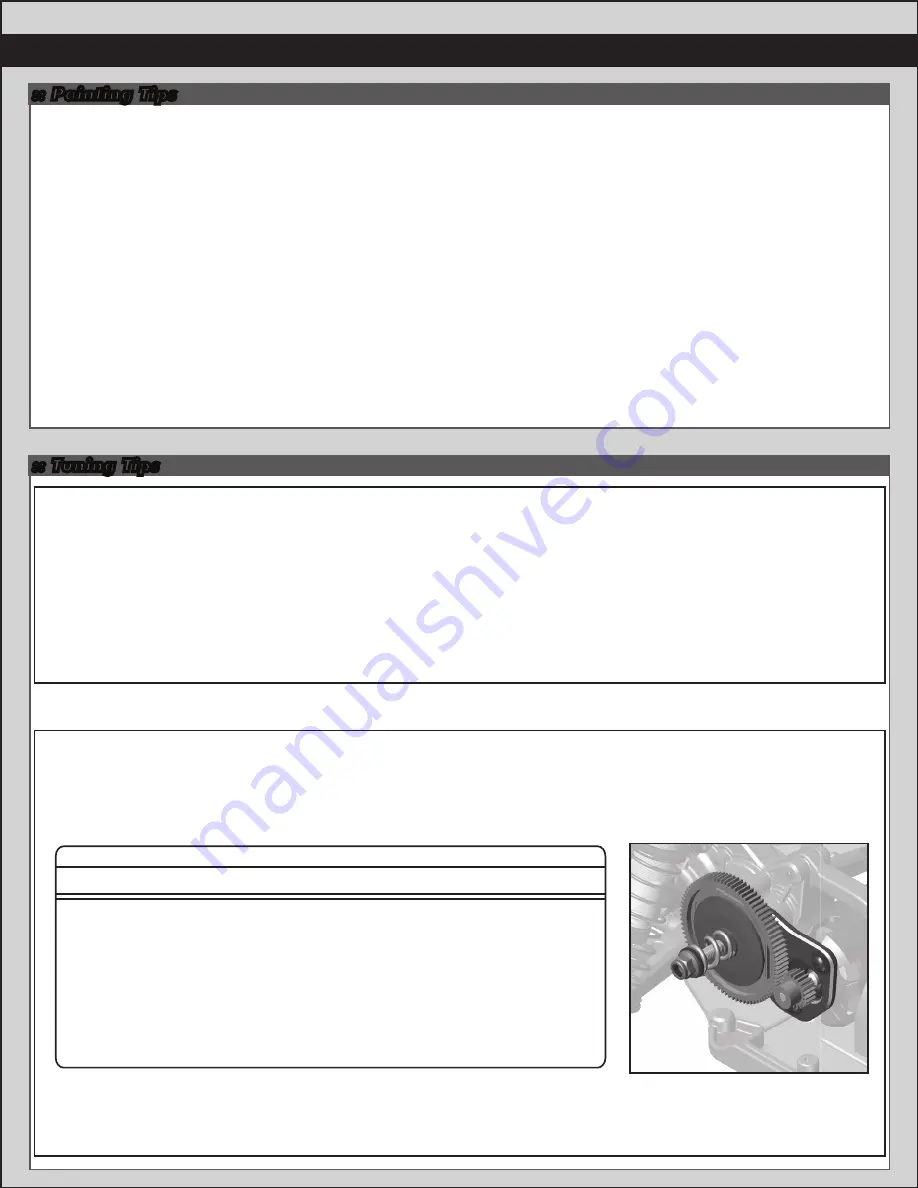

Motor Gearing:

Proper motor gearing will result in maximum performance and run time while reducing the chance of overheating and

premature motor failure. The gear ratio chart lists recommended

starting gear ratios

for the most widely used

motor types. Gear ratios will vary depending upon motor brand, wind, and electronic speed control. Consult your

motor and electronic speed control manufacturers for more information.

Team Associated is not responsible for motor damage due to improper gearing.

Set The Gear Mesh:

You should be able to rock the spur gear back and forth in the teeth of the pinion gear without making the pinion gear

move. If the spur gear mesh is tight, then loosen the #31532 screws and move the motor away, then try again.

A gear mesh that is too tight or too loose will reduce power and damage the gear teeth.

31

30

24

23

22

21

20

21

21

19

18

Pinion

69

75

78

78

78

78

78

81

81

81

81

Spur

5.79:1

6.50:1

8.45:1

8.82:1

9.22:1

9.65:1

10.14:1

10.03:1

10.03:1

11.08:1

11.70:1

Final Drive Ratio

17.5 Reedy Sonic Brushless

13.5 Reedy Sonic Brushless

10.5 Reedy Sonic Brushless

9.5 Reedy Sonic Brushless

8.5 Reedy Sonic Brushless

7.5 Reedy Sonic Brushless

6.5 Reedy Sonic Brushless

3300kV Brushless

3900kV Brushless

4900kV Brushless

6100kV Brushless

Motor

B6 Gear Ratio Chart (Internal Gear Ratio 2.60:1)

Summary of Contents for RC10B6

Page 1: ... 90011 RC10B6 Team Kit ...