68

60T - 280T

COSMOGAS

16 - START-UP

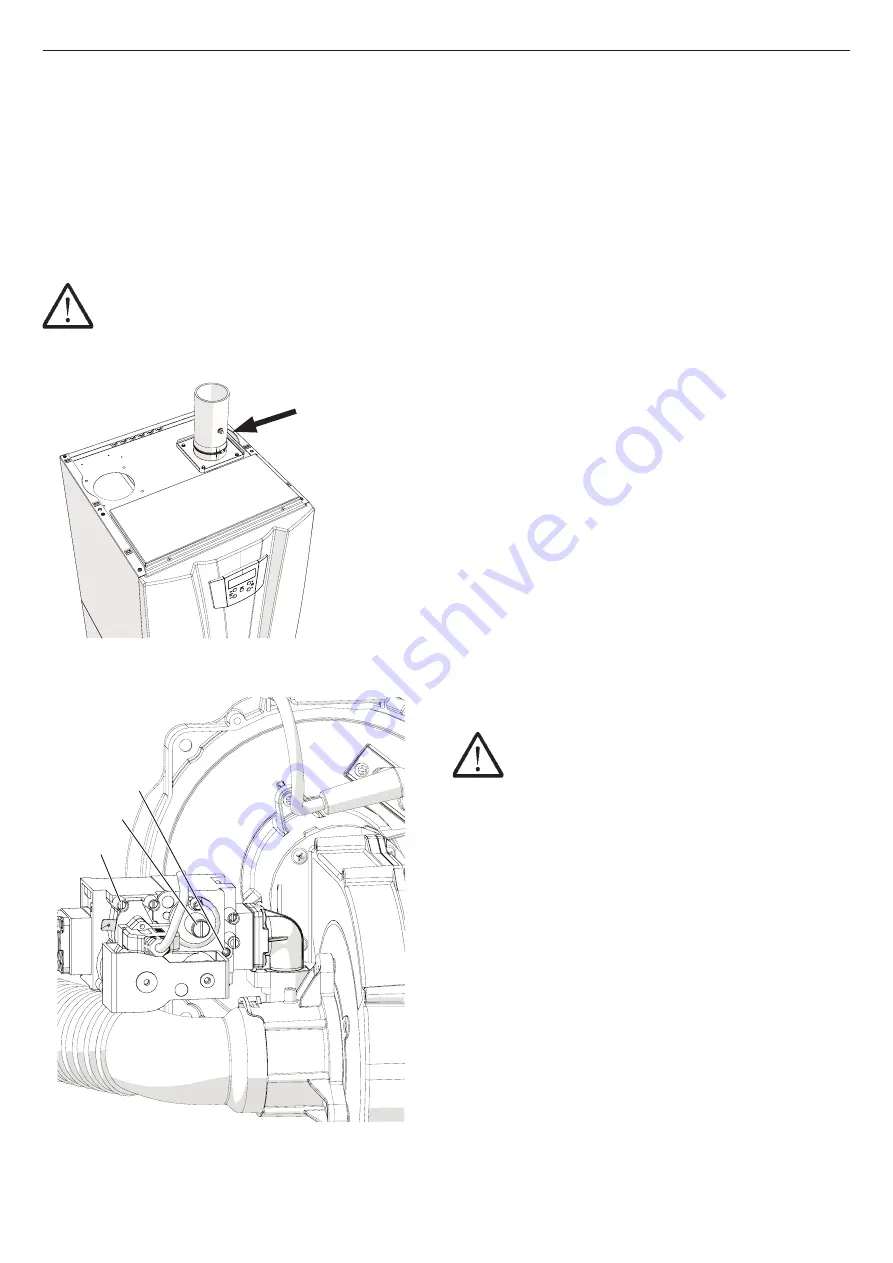

Figure 16-9 - Taking combustion analysis

Figure 16-10 – Gas valve

D - Gas inlet tapping point.

E - CO2 regulation screw.

F - Factory regulation screw (do not touch).

E

D

F

E

D

F

020010.01.022

16.8 - Controlling the level of

CO2 and any adjustments

Table 16-8 shows the correct values of CO2 for a boiler

working in normal conditions, at an altitude of less than 1000

metres. A different value from the one shown can cause

malfunctions. A combustion analysis must be carried out to

check and make any necessary adjustment to this value.

Proceed as follows:

16.8.1 - Check the CO2 content and make

any necessary adjustment on boiler

models 70T

WARNING! If during this procedure a CO value

of more than 1000 ppm is detected, turn off the boiler

and contact the dealer.

1.- If one is not already present, you will have to make a hole

for the combustion analysis, located about 200 mm from the

exhaust gases outlet pipe (see figure 16-9 corresponding to

stopper “F”).

2.- Turn on the boiler and open the link between terminals “10”

and “11”;

3.- Make sure that the temperature demanded is higher than

that of the boiler/hot water heater;

4.- Go into the installer menu (see section 17.15) and set

parameter

2010

to

HIGH.

Now the boiler will operate

at maximum power for 20 minutes;

5.- Wait two or three minutes for the CO2 to stabilise;

6.- Insert the sensor to read the value of CO2 in point “F” shown

in figure 16-9;

7.- Compare the value of CO2 detected with that shown in table

16-8; make sure you read the value for the type of gas being

used. If the value of CO2 is not that shown in table 16-8, you

must correct it using screw “E” in figure 16-10. Using a 2.5

mm six-sided spanner (turn the screw clockwise to reduce

the value of CO2 and anticlockwise to increase it), make

small turns, always waiting for the CO2 value to stabilise

before continuing with further movements, until you reach

the desired value.

8.- Once you have reached the correct value of CO2 as in table

16-8, seal the screw with red paint or a similar system to

discourage any tampering with it.

9.- Set parameter

2010

at

LO

. The boiler will now operate

at minimum power for 20 minutes.

10.- Wait two or three minutes for the CO2 to stabilise;

11.- Compare the reading for the value of CO2 with that shown

in table 16-8, make sure you read the value for the type of

gas being used. The value of CO2 must fall within the values

shown, if that is not the case you must turn off the boiler and

contact the manufacturer.

12.- Set parameter

2010

to

OFF

to return the boiler to

normal operation.

13.- Close the combustion analysis hole in figure 16-9, with

a suitable stopper “F” as shown in the manufacturer’s

instructions for the outlet pipe.

WARNING! Once stopper “F” is in position with

the boiler at maximum power, check there are no leaks

of exhaust gases.

F - Taking combustion analysis

F

020010.01.042