10

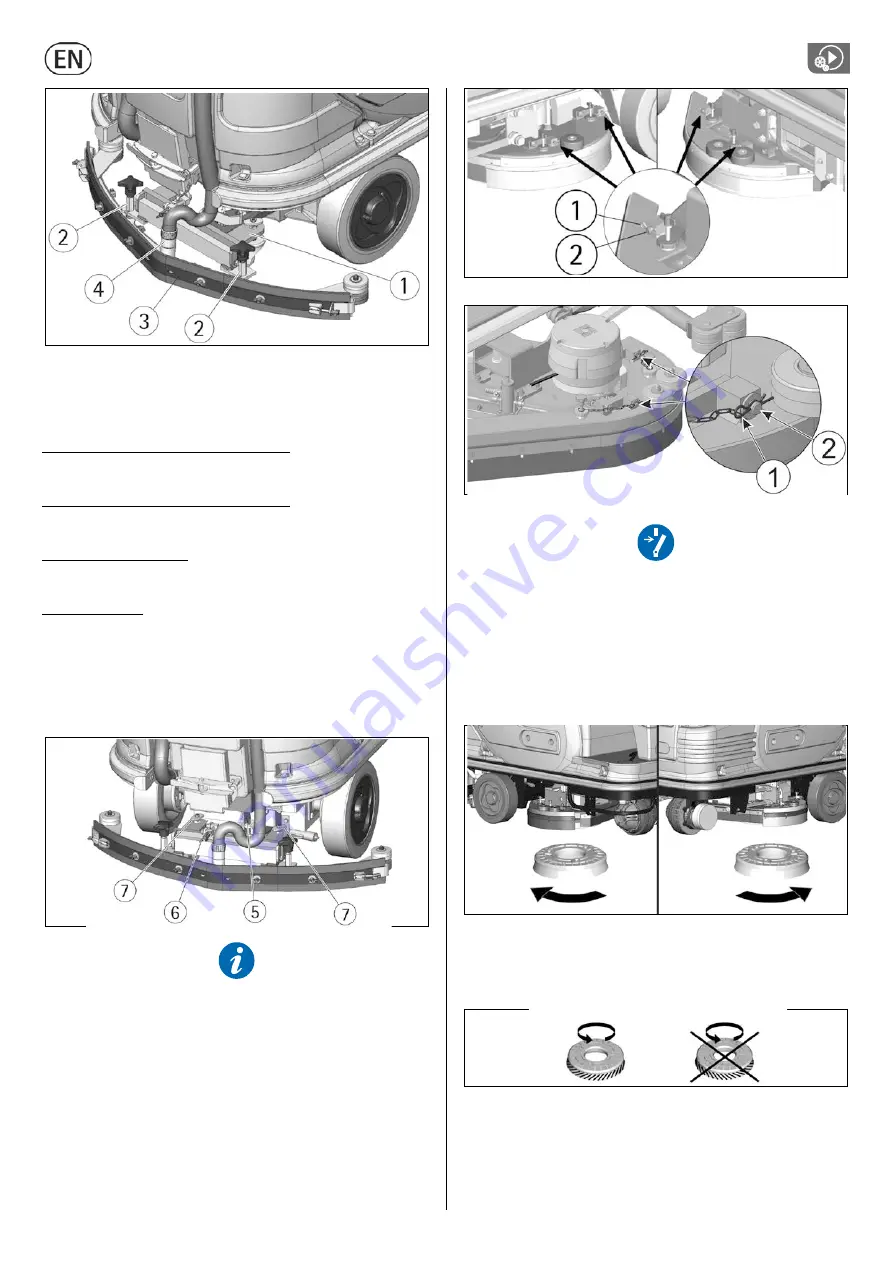

ADJUSTING THE SQUEEGEE

In order to have a perfect drying result through the squeegee, the rear

rubber must have the lower bending uniformly adjusted in all its length.

For the adjustment, it is necessary to put oneself in working condition

and therefore the suction motor has to be switched on and the brushes

have to function together with the detergent solution.

The lower part of the rubber is too much bent

Take off the pressure rotating the wing nut (5) counterclockwise.

The lower part of the rubber is not much bent

Increase the pressure rotating the wing nut (5) clockwise. Check that

the wheels which adjust the height do not rest on the floor, in this case

adjust them as indicated in paragraph "Height adjustment".

The bending is not uniform

Adjust the squeegee inclination rotating counterclockwise the wing nut

(6) to increase the bending in the central part, or clockwise to increase

the bending on the extremities.

Height adjustment

Once that the pressure and inclination of the squeegee have been

adjusted, it is necessary to fix this optimum condition making touch

slightly the wheels onto the floor. Rotate clockwise the registers (7) to

lower the wheels or counterclockwise to raise them. Both wheels must

be adjusted in the same measure. To act upon the register (7) loosen at

the same time the two milled ring nuts, adjust the height acting on the

upper one and then fix the adjustment screwing and blocking the lower

one.

Every type of floor requires a specific adjustment. For example, concrete

floors (where the friction results to be high) need little pressure, while

smooth floors (ceramics) need higher pressure.

If the cleaning operations are made always on the same type of floor,

the adjustment can change only in function of the rubber wear.

ASSEMBLING THE SPLASHGUARDS

The two slash guards are already preassembled on the two metal covers.

To assemble the covers, it is necessary to proceed as follows:

1.

Take off the clips (1) present on the pins (2) fixed to the brushes

base.

2.

Assemble the cover onto the brushes base.

3.

Reposition the clips (1) to block.

For the disassembly it is necessary to proceed inversely with above-

mentioned operation

(version 100)

(Version 130)

BRUSHES ASSEMBLY

To assemble the brushes it is necessary that the brushes base is in the

lifted position. If it is not lifted, proceed as follows:

Without the operator seated, turning the key switch clockwise, the

display comes on and after 3 seconds all working groups come off

automatically and are lifted from the floor.

With the brushes base group in lifted position, insert the brushes into

their plate seat underneath the brushes base turning them until the

three metal buttons are properly seated in their slots; rotate energically

the brushes to push the button towards the coupling spring until they

get blocked.

The figure shows the rotating sense for brushes coupling.

For a longer life of the brushes we suggest to invert daily their position.

Whenever brushes result to be deformed we suggest to reassemble

them in the same position, in order to avoid that the different

inclination of the bristles causes excessive motor overload or

troublesome vibrations.

FLOOR CLEANING

RECOVERY TANK

Verify that the squeegee hose couplings (1/2) are correctly inserted into

their seats and that the exhaust hose plug (4) placed in the rear part of

the machine is well closed.