GB

GB

BEFORE USE

HANDLING OF THE PACKED MACHINE

The machine is supplied with suitable packing.

The total weight is 50 kg (max).

Packing dimensions:

without pallet:

Base:

80 cm x 43 cm

Height:

65 cm

with pallet:

Base:

80 cm x 43 cm

Height:

75 cm

ATTENTION:

Do not stack more than 2 machines.

UNPACKING OF THE MACHINE

1. Remove the outer package.

2. Loosen the two nuts that fix the two brackets to

the machine.

3. Unscrew the screws that fix the brackets to the

pallet and remove the brackets.

4. Retighten the two nuts into their initial position

onto the machine, necessary for the tank blocking.

5. Bring the handle bar into working position (see

under “MOVEMENTS OF THE HANDLE BAR”) to lower

the machine from the pallet and pushing it forwards

by the wheels inclining the machine a little back-

wards to avoid heavy contacts to the mechanical

parts.

6. Keep the packaging for eventual transport needs.

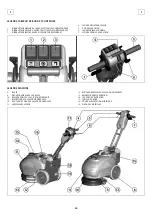

MOVEMENTS OF THE HANDLE BAR

The handle bar in the package arrives in closed posi-

tion.

To rotate the handle bar into one of the different

working positions:

1. Pull up the release lever (7) near the handle bars.

2. Rotate the handle bar into the working position

while holding the release lever (7).

3. Let go of the release lever (7) to lock the handle

bar.

Use the same procedure for further height adjust-

ment of the handle bar in order to find the most

comfortable working position.

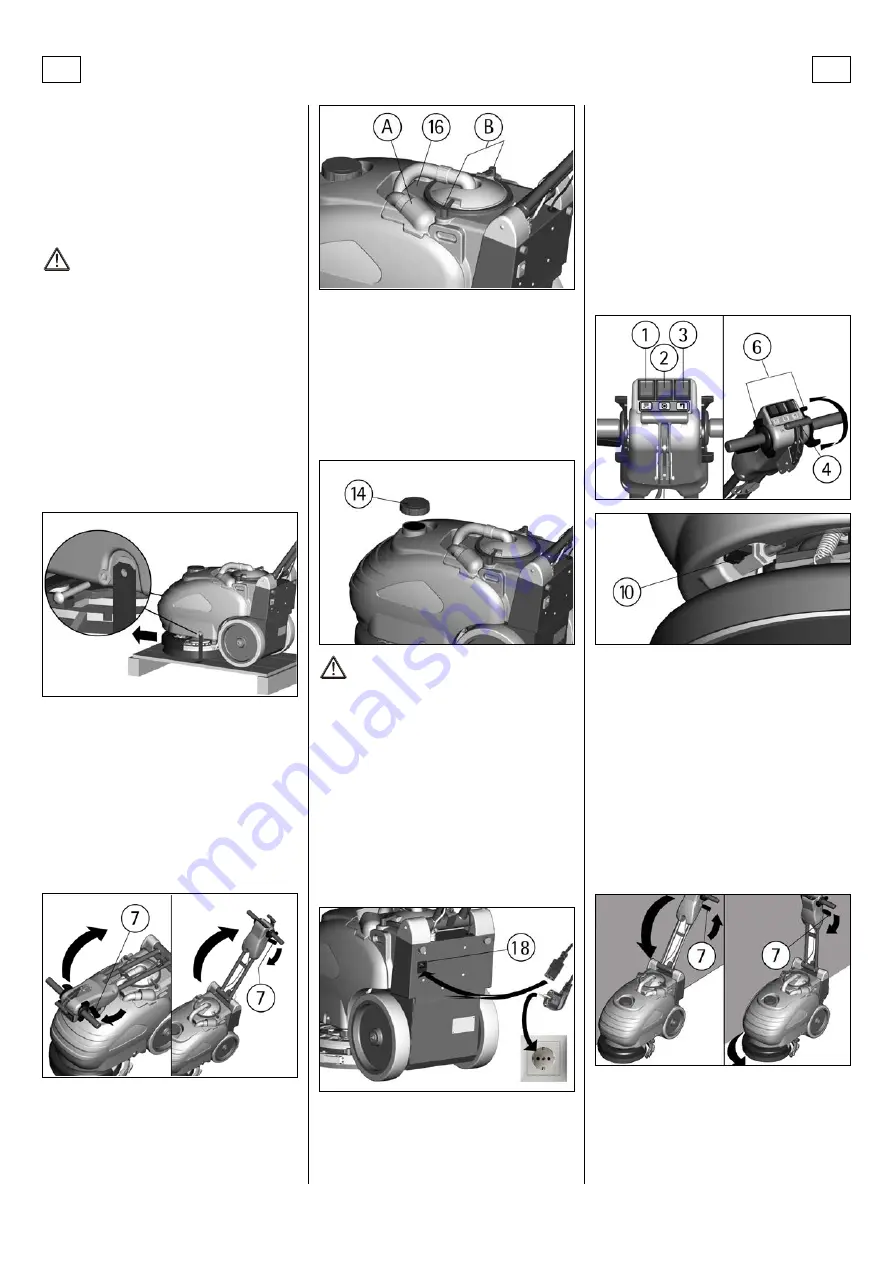

RECOVERY TANK

Check that the cover of the suction filter (16) is cor-

rectly secured, after rotating the levers (B). Further-

more, check that the squeegee hose is correctly seat-

ed in its seat (A).

SOLUTION TANK

The capacity of the solution tank is indicated in the

technical data.

Open the screw plug (14) situated on top and fill the

solution tank with clean water at a maximum tem-

perature of 50°C. Add the liquid detergent in the

percentage recommended by the manufacturer. To

avoid excessive foaming, which could cause prob-

lems to the suction motor, use the minimum per-

centage of detergent. Screw down the plug to close

the tank.

ATTENTION:

Use always low foam detergent. To avoid excessive

foaming, before starting working operation, add into

the recovery tank a minimum quantity of anti-foam

product.

Never use acid.

FLOOR CLEANING

STARTING OF THE MACHINE

The machine is equipped with a mains cable com-

plete with a plug for the connection to the mains

system and with a socket connector to insert inside

the plug (20) situated behind the machine.

1. Insert the socket inside the machine plug (18).

2. Insert the plug into the appropriate mains socket.

3. Lower the squeegee by rotating downwards the

handle of the squeegee lifting lever (4) placed in the

centre of the handle bar.

4. Press the switch for the brush motor (1).

5. Press the switch for the suction motor (2).

6. Press the switch for the solenoid valve (3).

The machine is equipped with a solenoid valve,

which activates the solution flow automatically

when the scrub control levers (6) are engaged. Re-

leasing these levers will stop the flow automatically.

7. Activating the levers (6) the brush will start ro-

tating. The solution flow begins and the squeegee

will start drying the floor.

8. During the first few meters check that the solu-

tion flow is appropriate. The flow adjuster of the so-

lution is already adjusted at the factory to satisfy the

cleaning of most floors. If it is necessary to adjust

the quantity of solution onto the floor, adjust the

lever of the flow adjuster

(10).

9. When moving the machine backwards, make sure

that the squeegee is lifted.

HANDLE BAR ADJUSTMENT

When approaching obstacles or near walls, it is pos-

sible to simplify the handling of the machine by ad-

justing the handle bar more vertically with respect to

the machine.

To rotate the handle bar:

1. Pull up the release lever (7) near the handle bars.

2. Rotate the handle bar into the new working posi-

tion keeping the release lever (7) pulled.

3. Release the lever (7) to lock the handle bar in the

desired position.

Once the obstacle has been passed and the maneu-

ver completed repeat the operation to return to the

previous working position.

This operation is possible also with the machine in

motion maintaining pressed contemporarily the

handle bar levers (6) and the release lever (7).

OVERFILL PROTECTION

In order to avoid serious damages to the suction mo-

tor, the machine is equipped with a float that inter-

venes when the recovery tank is full, closing the suc-

tion hose and stopping the suction.

When this happens, it is necessary to empty the re-

covery tank.

17

Summary of Contents for Baby-e

Page 2: ......