Quick Start

20

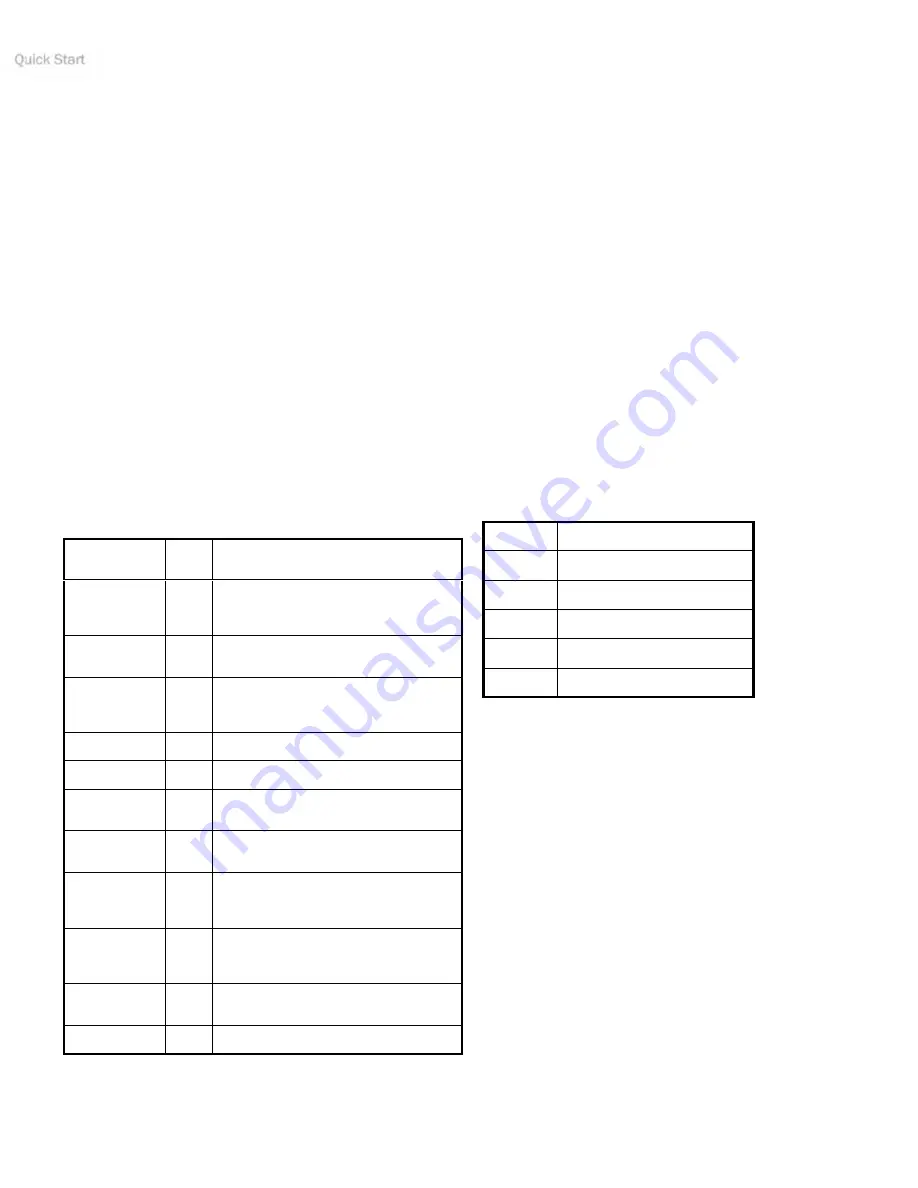

Table 2. Keyboard teleoperation

KEY

ACTION

↑

forward

↓

reverse

←

turn left

→

turn right

space

all stop

Table 3. ARIA demo operation modes

MODE

HOT

K

EY

DESCRIPTION

laser

l

Displays

the

closest

and

furthest readings from the laser

range finder

io

i

Displays the digital and analog-

to-digital I/O ports

position

p

Displays the coordinates of the

robot’s position relative to its

starting location

bumps

b

Displays bumpers status

SONAR

s

Displays the SONAR readings

camera

c

Controls and exercises the pan-

tilt-zoom robotic camera

gripper

g

Controls, exercises and displays

status of the Gripper accessory

wander

w

Sends the robot to move around

at its own whim while avoiding

obstacles

teleop

t

Drive and steer the robot via

the keyboard or a joystick;

avoids collisions

unguarded

u

Same

as

teleop,

except

no

collision avoidance

direct

d

Direct command mode

A Successful Connection

ARIA prints out lots of diagnostic text as it negotiates a connection with the robot. If successful, the client requests

various ARCOS servers to start their activities, including SONAR polling, position integration and so on. The

microcontroller sounds an audible connection cue and you should hear the robot’s SONAR ping with a distinctive and

repetitive clicking. In addition, the motors-associated

STATUS

LED on the User Control Panel should flash very fast (was

flashing slowly while awaiting connection). Note that the ARIA demo automatically engages your robot’s motors though

a special client command. Normally, the motors are disengaged when first connecting.

The amber

SERIAL

port indicator LEDs on the robot’s User Control Panel should blink to indicate ARIA-client to ARCOS-

server communications, too.

O

PERATING THE

ARIA

D

EMONSTRATION

C

LIENT

When connected with the ARIA demo client, your robot becomes responsive and intelligent. For example, it moves

cautiously. Although it may drive toward an obstacle, your robot will not crash because the ARIA demo includes

obstacle-avoidance behaviors which enable the robot to detect and actively avoid collisions.

The ARIA demo displays a menu of robot operation options. The default mode of operation is

teleop

. In

teleop

mode, you drive the robot manually, using the arrow keys on your keyboard or a joystick connected to the client PC’s

joystick port (as opposed to a joystick port on the robot).

While driving from the keyboard, hold down the

respective keys to simultaneously drive the robot

forward or backward and turn right or left. For

instance, hold down the up-arrow key to have the

robot accelerate forward to its cruising speed of

around 400 millimeters per second (defined in the

source code). Release the arrow key to have the

robot slow down and stop. Press and hold the

right- or left-arrow key to have the robot rotate or

turn in an arc if you also hold down the up- or

down-arrow key.

The other modes of ARIA demo operation give you

access to your robot’s various sensors and

accessories, including encoders, SONAR, laser,

Gripper, a pan-tilt-zoom robotic camera, I/O port

states, bumpers and more. Accor-dingly, use the

ARIA demo not only as a demonstration tool, but as

a

diagnostic one, as well, if you suspect a sensor or

effector has failed or is working poorly. The demo

also is useful for calibrating your robot’s drive