2. Charging Operation

1.

Plug the battery charger into the proper AC power source. The charging indicator light

will flicker in green color and the charger operates in standby mode.

2.

Insert the battery pack fully into the battery charger and the charger starts charging.

The battery charger can detect some sort of failure caused by the battery and indicates by the

statuses of the red and green indicator lights.

When a failure occurs, remove the battery

and then insert it into the charger again. If the

failure continues, change with a new battery.

If the new battery can be charged, then the

old battery maybe damaged. If the charging

indicator lights indicate same failure as

before while changing with a new battery,

then the charger maybe damaged, take the

charger to be repaired by qualified

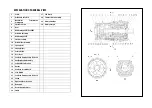

serviceman. (Fig. 5)

The following chart lists the relations between the statuses of charging and charging

indicator lights.

Descriptions of

Charging Status

Icons

Icons of Charging

Indicator Lights

Descriptions of

Charging Indicator

Lights

Green

Light

Red

Light

Plug the charger into

a proper outlet

Green light flickers, red

light extinguished

During charging

Green light extinguished,

red light keeps

flickering steadily

Charge complete

Green light keeps up

steadily, red light

extinguished

Abnormity occurs on

the battery

Green and red light

flicker alternately

The temperature of

the battery is under

0

℃

or higher than

50

℃

Green light extinguished,

red light flickers

Installing or Removing Tool

The tool here includes driver bit, drill bit, etc, which differs from the concept of power tools

or machines.

CAUTION:

Before operation, always set the reversing

switch lever in the central position

and

remove the battery. Mustn’t press switch

trigger.

1. Installing instrument

Hold the ring and turn the sleeve

counterclockwise to open the chuck jaws.

Place the bit in the chuck as far as it will go.

Hold the ring firmly and turn the sleeve

clockwise to tighten the chuck (view backwards). (Fig. 6)

Model

FFCL18-01

FFCL18-03

SCHARG-001

FFCL18-04

SCHARG-001

(FFCL18-05)

Input Voltage (AC)

220-240V

110-240V

220-240

Charging Current

3.0A

2.0A

Input Power Frequency

50-60Hz

Applicable Battery Cartridge Voltage

(DC)

14.4-18V

Full Charging Time

2.0Ah

≈45min

≈70min

4.0Ah

≈90min

≈135min

Insulation Grade

Double Insulation

Summary of Contents for MAC AFRIC SDRILC-005

Page 1: ......