8

TECH TANK

5. DI FLOW

DIGITAL METER

; DI FLOW IN-LINE

DIGITAL FLOW METER

3. INSTALLATION AND USE

3.1 DISPLAY ORIENTATION

The meter is supplied with a calibration carried

out for liquid diesel at 20 °C. Calibration is

required when metering a different fluid, after

disassembly, at different temperature or after

significant wear. A proving container or a con-

tainer of KNOWN volume will be needed for the

calibration procedure. It is possible to invert the

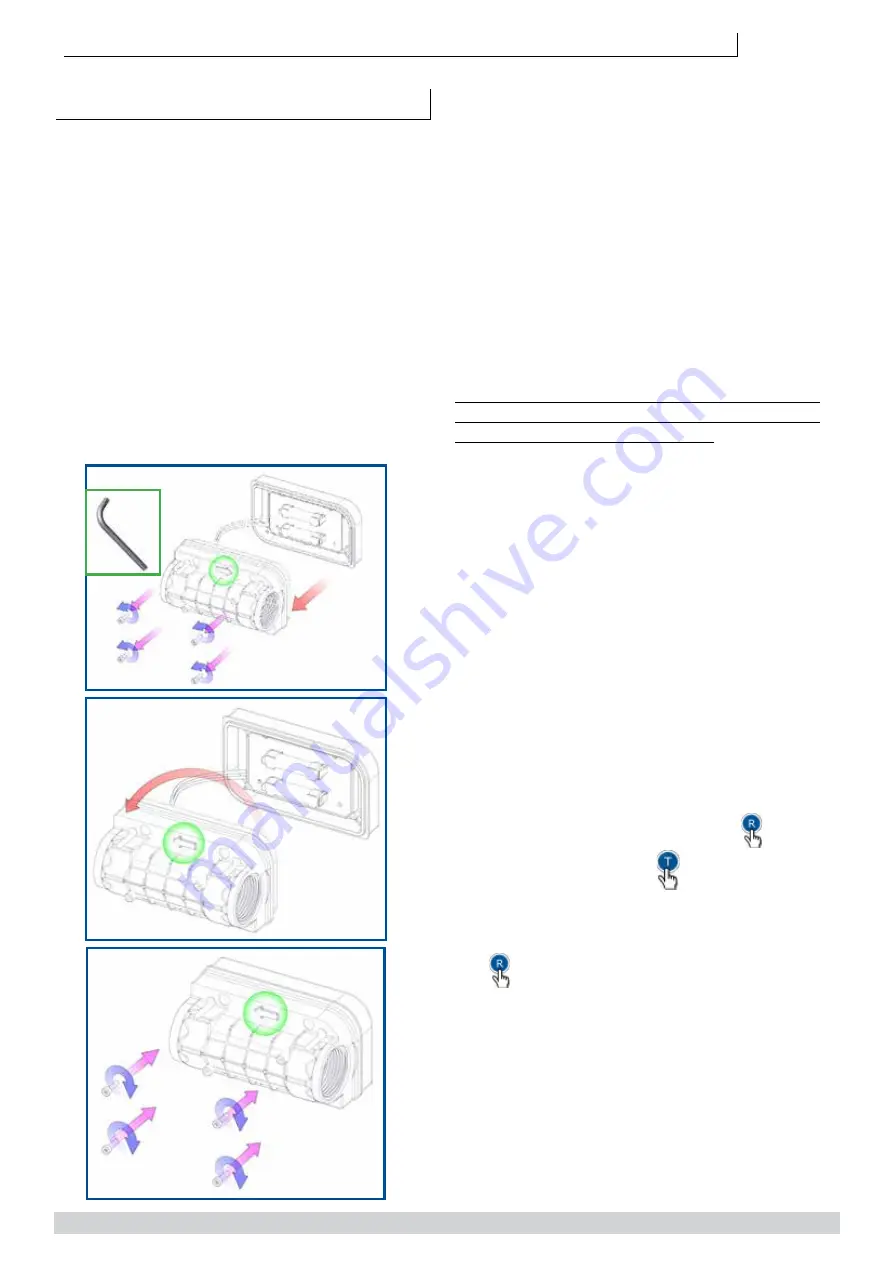

flow direction using following steps:

1. Remove the 4 screws from the back of the

meter

2. Rotate the meter body by 180°

3. Reposition the body on the cover taking care of

not squeezing wires.

4. Screw the 4 screws to tighten the body to the

cover.

3.2 CONNECTIONS

When adding the flow meter to a existing sys-

tem, connect the flow meter inlet to the outlet

at of the pump, and connect the delivery

hose into the flow meter outlet. It is important

to respect the flow direction looking at the arrows

on the meter body. In case you need the opposite

flow, rotate the meter as described above in para-

graph 3.1.

The meter has a double Reed switch system to

avoid false readings due to vibrations or erroneous

installation and turbine reverse rotation. The meter

is threaded 1” BSP-P female both at inlet and out-

let. Sealing is made using O - ring 30x3 70Sh.

1

2

3

2.5

It is necessary, if not already installed in the

system, to install a filter or screen of at least

40 mesh prior to the flow meter

.

3.2.1 ELECTRICAL WIRING FOR PULSER

VERSION

If you bought our pulser model, the flowmeter is

fitted with a 2m cable with 5 internal wirers to be

connected as follows:

1. Yellow wire: power + 12 Vdc

2. Brown wire: power 0 Vdc

3. Green wire: pulser channel 100 imp/unit

4. White and grey wires: Relay contact should you

desire to control the pump with the meter ( max

24Vdc 500mAh)

Once connected to power supply, the meter will

“Beep”, this sound beeps at each button pressure

(this happens only with pulser version).

It is important to know that the system is genera-

ting pulses 0-12Vdc with maximum frequency 2

milliseconds.

Should the meter control the pump, the

button

will activate the pump while

button stops it.

Two default settings are available and settable in

the system:

1. 60 seconds: to start the transaction after pres-

sing button

2. 20 seconds: seconds without pulse will stop the

transaction.