19

BURNER CHARACTERISTICS

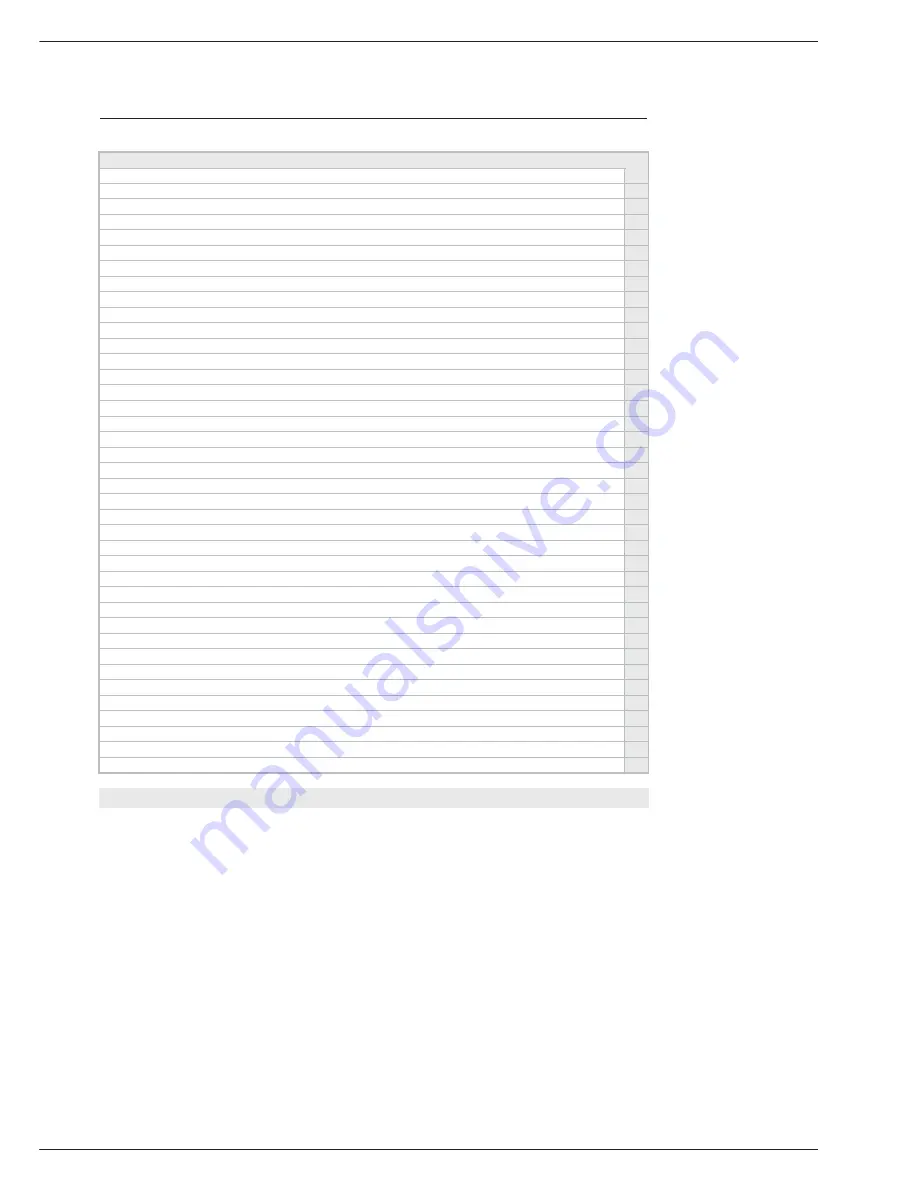

Corrective measures

Fit lining in the chimney

1

Increase the boiler T°

2

Check and clean the chimney

3

Check and clean the chimney

4

Comply with local requirements governing boiler room ventilation

5

Clean the burner and the boiler

6

Clean the burner and the boiler

7

Set the room thermostat to the required temperature

8

Free the pump or replace it

9

Move the switch to the Winter position or replace it

10

Properly fill and vent the system and the boiler

11

Open the radiator taps or adjust the thermostat valves

12

Properly fill and vent the system and the boiler

13

Check that the pipes and the meter are suitable for the system

14

Check that the pipes and the meter are suitable for the system

15

Replace the boiler thermostat/potentiometer

16

Ensure that the electrical system complies with regulations

17

Replace the fuses and look for the cause of the problem

18

Properly fill and vent the system and the boiler

19

Adhere to the performance data as indicated by ACV

20

Adhere to the performance data as indicated by ACV

21

Set the thermostat to the required temperature or replace it

22

Replace the Summer/Winter switch

23

Replace the main switch

24

Replace the NTC sensor

25

Replace the boiler thermostat/potentiometer

26

Abnormal situation

27

Replace the p.c.b.

28

Replace the p.c.b. but look for the cause of the malfunction

29

Replace the fan

30

Replace the p.c.b. if the fan turns but does not send a PWM signal

31

Replace the electrode or set it correctly

32

Replace the electrode or set it correctly

33

Insert the connectors correctly

34

Replace the gas valve and set it up according to the setting parameters

35

Replace the p.c.b.

36

Replace the boiler thermostat/potentiometer

37

Fill and vent the system and the boiler

38

Insert the NTC sensor in the pocket correctly

39

ACV provides details of training courses on the maintenance of BG 2000 burners

TABLE OF CORRECTIVE MEASURES