10

STARTUP & ADJUSTMENTS

Pre-Start Checklist

The following check list should be observed prior to starting

the unit.

√

Is the unit level? Unit should be level or slightly slanted toward

the drain for proper condensate drainage.

√

Is the unit installed with the proper clearances as listed on

√

Is the wiring correct according to the wiring diagram and

electrical codes?

√

Are all the wiring connections tight? Check the condenser fan

to make sure it turns freely.

√

Is the overcurrent protection properly sized?

√

Is the thermostat wired correctly? Is it installed in a proper

location?

√

To achieve rated capacity and efficiency the compressor must

be exposed to refrigerant for at least 24 hours prior to running

and then must be run for a minimum of 12 hours.

Start-Up Procedure

CAUTION:

If the unit is equipped with a crankcase heater,

allow 24 hours prior to continuing the start up

procedures to allow for heating of the refrigerant

compressor crankcase. Failure to comply may

result in damage and could cause premature

failure of the system. This warning should be

followed at initial start up and any time the power

has been removed for 12 hours or longer.

The control circuit consists of an anti-short cycle timer that will

not let the compressor re-start before 5 minutes have elapsed.

1. Set the system mode to OFF and the temperature mode to

its highest setting.

2. Turn power on at the disconnect switch.

3. Set the system mode to ON or COOL.

4. Set the temperature mode below room temperature. Verify

that the indoor blower, outdoor fan, and compressor energize

and the cooling function starts.

5. Verify the discharge air grilles are adjusted and the system

air is balanced.

6. Verify the duct work has no air leaks.

7. Verify the condensate drain is installed correctly and functions

properly.

8. Set the temperature mode above room temperature. The unit

should stop.

9. Instruct the homeowner on unit and thermostat operation and

filter servicing.

Air Circulation

Leave the thermostat system mode on OFF, and set the fan

mode to ON. Blower should run continuously. Check the air

delivery at the supply registers and adjust register openings for

balanced air distribution. Examine ducts for leaks or obstruction

if insufficient air is detected.

Set the thermostat fan mode to AUTO. The blower should stop

running.

System Heating

Set the thermostat system mode to HEAT and the fan mode to

AUTO. Change the thermostat temperature selector above the

existing room temperature and check for the discharge of warm

air at the supply registers.

System Cooling

Set the thermostat’s system mode to COOL and the fan mode to

AUTO. Change the thermostat temperature selector below the

existing room temperature. Allow the cooling system to operate

for several minutes and check for the discharge of cool air at

the supply registers.

Short Cycle Protection

The control circuit is equipped with a time-delay feature for

protection against short cycling. With the system operating in

the cooling mode, gradually raise the thermostat temperature

setting until the whole system de-energizes. Immediately lower

the thermostat temperature to the original setting and verify that

the indoor blower is energized. After approximately 5 minutes

the compressor and the outdoor fan will energize.

Emergency Heat

(Available only when Electric heat is supplied)

1. Set the thermostat’s system mode to EM HT and the fan

mode to AUTO (intermittent air) or ON (continuous air).

2. Set the thermostat’s temperature selector above the existing

room temperature and check the following:

• The thermostat auxiliary heat is indicated as ON.

• The compressor and the fan should not run; low voltage

circuit remains energized.

• The blower runs according to the thermostat’s fan mode

setting.

Forced Defrost Mode (Field Test)

• When the

TEST

terminals are shorted for more than 3 seconds,

with the

Y1

input active and pressure switches closed, the

ACST will be eliminated and the compressor contactor output

energizes. The control will be placed into a forced defrost

mode.

NOTE:

The coil temperature sensor does not need to be cold

when the unit is forced into defrost.

• If the short across the TEST pins exist, the unit will stay

in DEFROST as long as the short remains or until the

TERMINATE TIME is reached (11 minutes). This will happen

regardless of coil temperature.

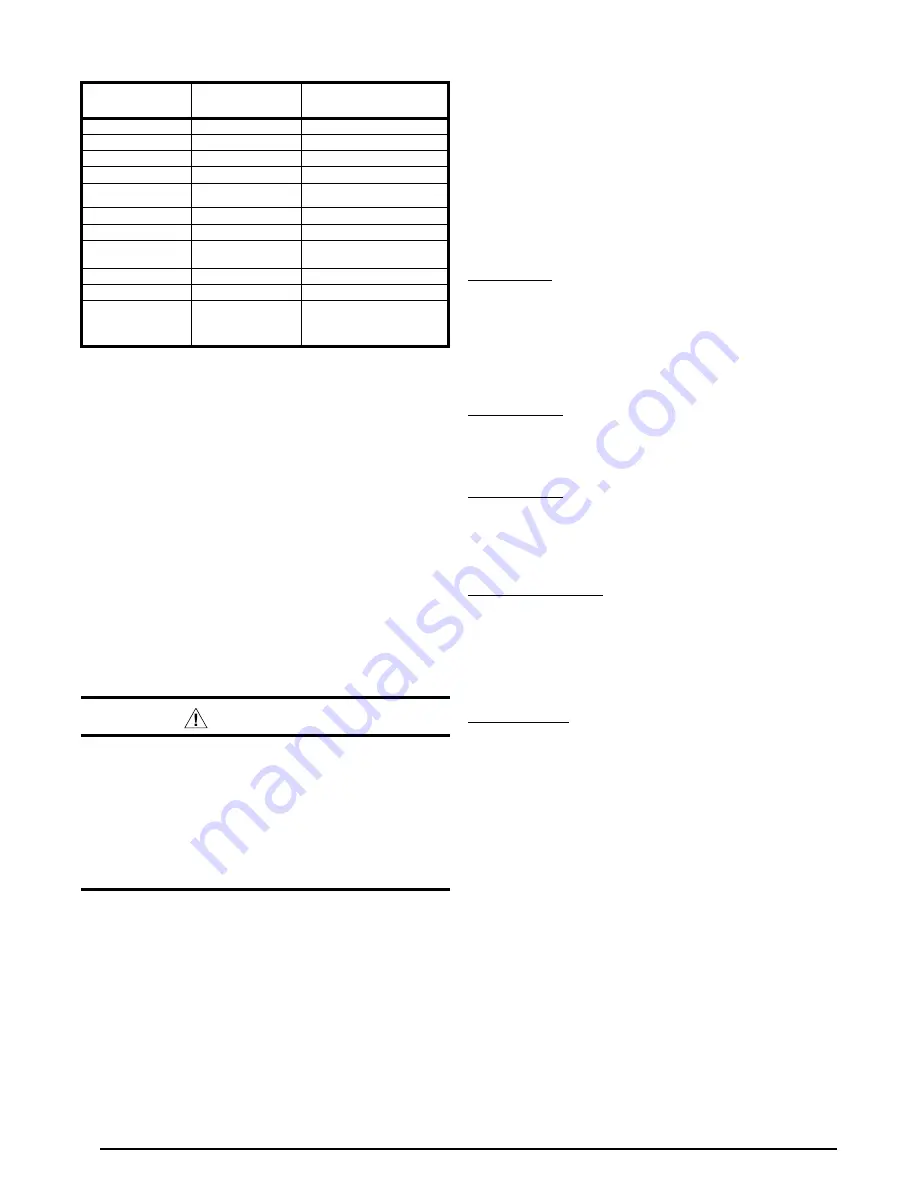

Table 2. Control Board Status Indicators

STATUS

INDICATOR

STATUS

TYPE

DIAGNOSTIC

DESCRIPTION

C1

Operating Status Cooling, 1st Stage

H1

Operating Status Heating, 1st Stage

SC

Operating Status Anti Short Cycle Timer

dF

Operating Status Defrost

_.

Operating Status Power on, no call for

operation

01

Fault

Pressure Switch, low

02

Fault

Pressure Switch, high

03

Fault

Temperature Sensor,

Ambient

04

Fault

Temperature Sensor, Coil

05

Fault

Board

dF

(flashing)

Input Error

Forced defrost - test

short applied longer than

11 minutes