PerfectSpeed

®

Motor and User Interface Troubleshooting

Motor Is Not Running

If the PerfectSpeed

®

motor with User Interface isn’t running, perform the following checks:

1. Ensure that both the PerfectSpeed

®

motor and User Interface have proper line voltage for intended application.

2. Turn the User Interface on-board potentiometer fully clockwise (100% demand) and check to see if the motor runs.

3. If 0-10 VDC input is in use, disconnect the external input from the User Interface and perform Check 2.

4. Check the digital read- out of User Interface for an error code:

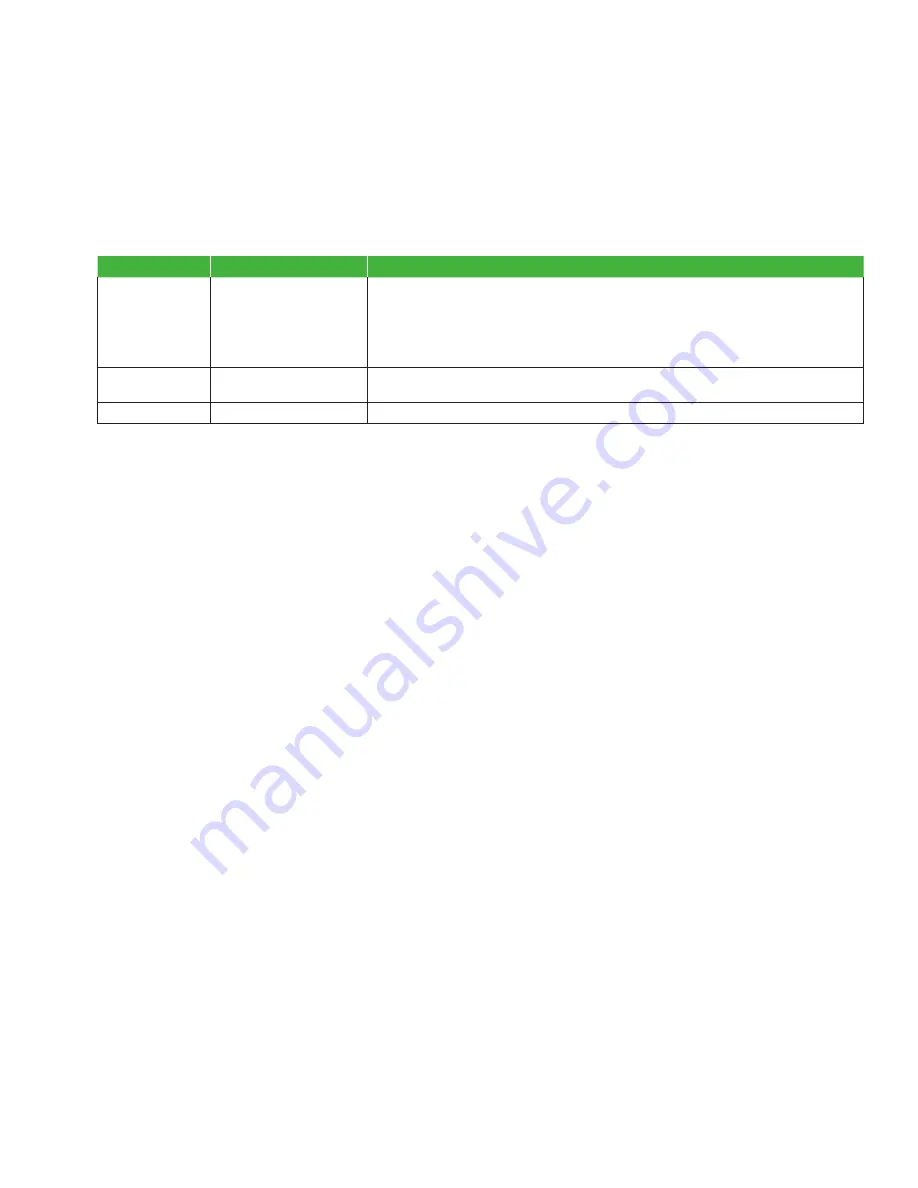

Error Code

Reason

Action

E1

No Communication

Remove power from both the PerfectSpeed

®

motor and User Interface for four (4)

minutes, then reconnect power and test again.

Check the communication cable connection between the PerfectSpeed® motor and

User Interface.

Check the continuity of communication cable (pin 1-1, pin 2-2 pin 3-4, and pin 4-3).

E2

Low Voltage

This is a reading from the PerfectSpeed

®

motor itself. Ensure that there is at least 71

VAC (for 115 VAC applications) or 142 VAC (for 230 VAC applications).

E3

Not a NMC Motor

Connect to a NMC motor.

Check 2: Electrical Troubleshooting

1. Disconnect or remove power to the equipment being

serviced and allow four (4) minutes for the capacitors to

discharge any residual voltage.

2. Check the rotation and speed of the motor. Determine if

the motor can spin freely by hand without effort or assisted

means. If any binding occurs, replace the motor and control

unit.

3. Determine whether the system is wired for 120 VAC power

or 240 VAC power.

4. Disconnect the power cord from the connector on the

control unit. Inspect the power cord for bent, damaged, or

recessed wires and terminals.

5. Disconnect or remove AC power to the equipment serviced

and allow four (4) minutes for the capacitors to discharge

any residual voltage.

6. Proceed to Check 3.

Check 3: Motor Verification

1. Disconnect or remove AC power to the equipment serviced

and allow four (4) minutes for the capacitors to discharge

any residual voltage.

2. Make sure that the motor shaft spins freely by hand without

effort in both directions.

3. DC motors can have a jump filling when rotating this is

perfectly normal, if motor does not rotate at all motor needs

to be replaced.

Final Checks of the Motor

1. Check the mounting and fastening of the motor and control

unit. Make sure the motor and the control unit are securely

attached together and mounted tightly in the system.

2. Check the control unit connectors. Inspect for shorts,

detached wiring, or loose connections.

3. Check the motor and verify the rotation of the driven load.

Make sure it spins freely by hand in both directions without

effort or assisted means.

4. Check all circuit breakers.

12