Mechanics Hoists

PAGE: 15

Model MH

MH-0214

2721 NE 4th Ave Pompano FL 33064| (954) 367-6116

Visit WWW.ACIHOIST.COM for the most current information

5.3 Frequent Inspection

Inspections should be made on a frequent basis in accordance with Table 6.3.1. Included in these Frequent Inspections

are observations made during operation for any defects or damage that might appear between Periodic Inspections.

Frequent Inspections shall be made by a designated person to ensure that the hoist is maintained in safe working

condition.

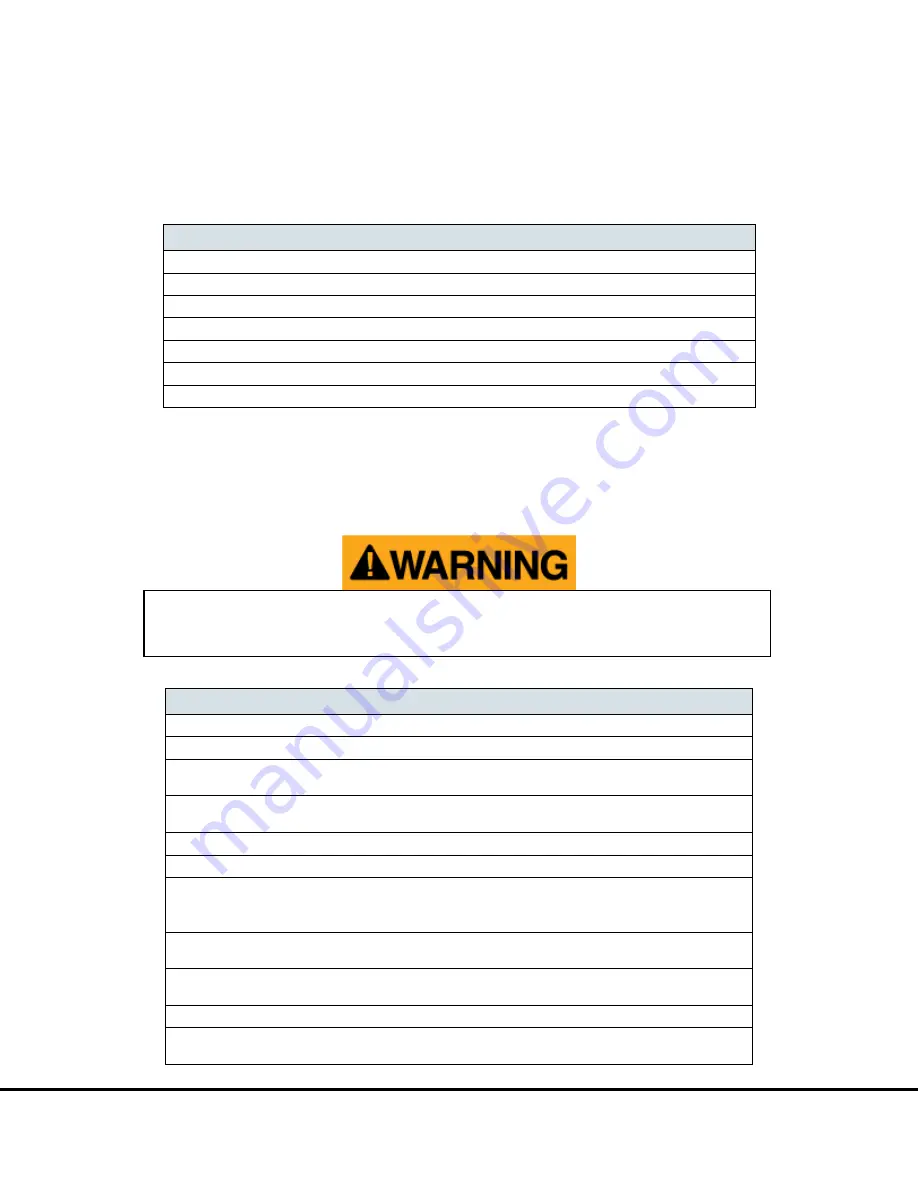

Table 6.3.1

FREQUENT INSPECTION

1. Check all functional operating mechanisms for maladjustment and unusual sounds.

2. Check the operation of the limit switch and associated components.

3. Check the hoist braking system for proper operation.

4. Check the hooks in accordance with ANSI/ASME B30.10.

5. Check the hook latch operation.

6. Check the Load Chain for twists, cracks, dents, wear and obstructions.

7. Check the Load Chain reeving.

5.4 Periodic Inspection

Inspections should be made on a Periodic basis in accordance with Table 6.4.1. Evaluation and resolution of the results

of Periodic Inspections shall be made by a designated person to ensure that the hoist is maintained in safe working

condition.

Table 6.4.1

PERIODIC INSPECTION

1. Complete the requirements of Frequent Inspection.

2. Check to ensure there is no evidence of loose bolts, nuts or rivets.

3. Check to ensure there is no evidence of damage or excessive wear of load and

idler sheaves.

4. Check to ensure there is no evidence of damage to hook retaining nuts or collars

and pins, and welds or rivets used to secure the retaining members.

5. Check to ensure the warning label is properly attached to the hoist and legible.

6. Check to ensure the function labels on the pendant control stations are legible.

7. Check to ensure there is no evidence of worn, corroded, cracked or distorted parts

such as load blocks, suspension housing, chain attachments, clevises, yokes,

suspension bolts, shafts, gears, bearings, pins and rollers.

8. Check to ensure there is no evidence of damage to the supporting structure or

trolley, if used.

9. Check to ensure there is no evidence of damage to the end connections of the

load chain.

10. Check to ensure there is no evidence of excessive wear on motor or load brake.

11. Check to ensure there is no electrical apparatus for signs of pitting or any

deterioration of visible controller contacts.

For inspections where load suspension parts of the hoist are disassembled, a load test

per ANSI/ASME B30.16 must be performed on the hoist after it is re-assembled and prior

to its return to service.