- 28 -

5. Level 1 Cosmetic / Appearance / Alignment Service

5.1 Alignment procedure (for function adjustment)

A list of necessary alignments for the LCD monitor:

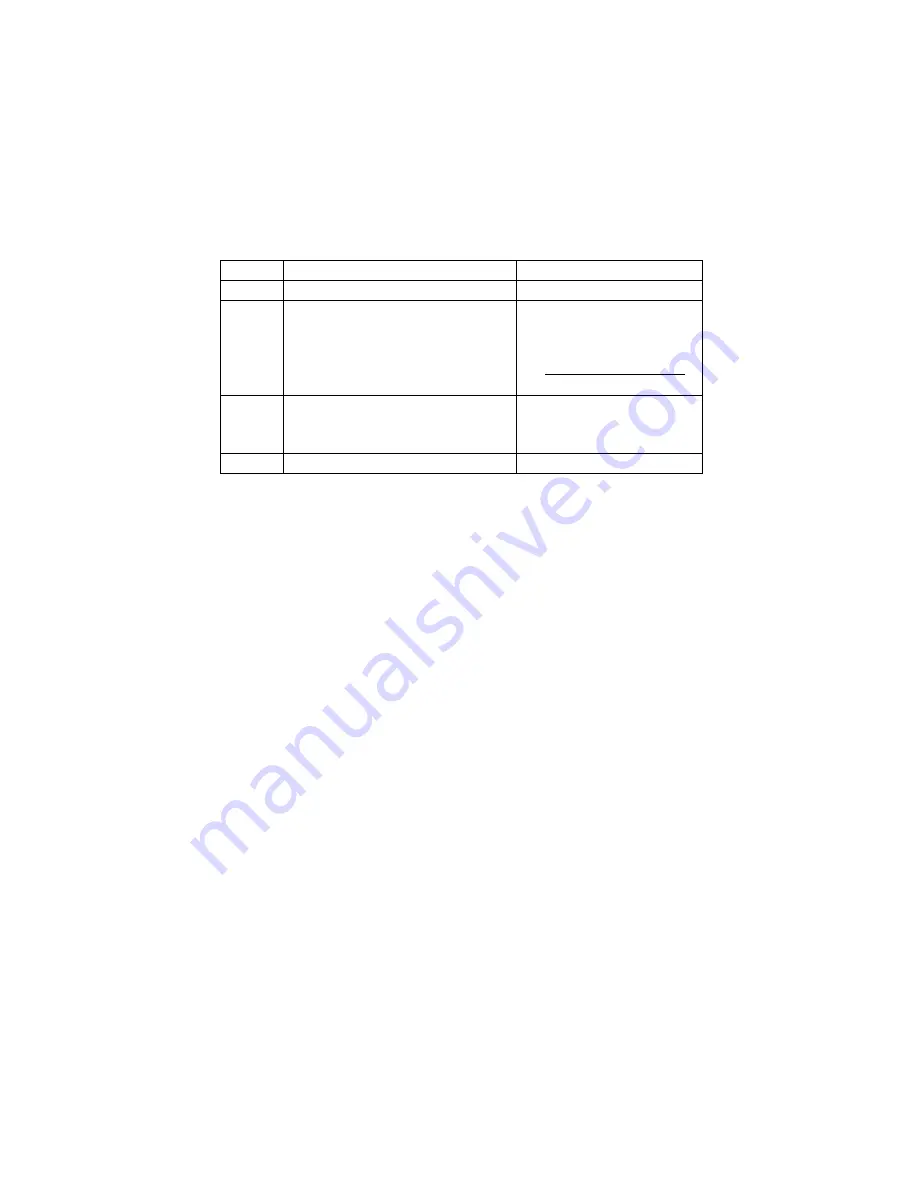

Items

Description

Remark

1

Timing adjustment

Preset timing

2

White balance adjustment

1. Burn In: On

2. User Mode

3. SXGA 1024

1280X1024@75Hz

Pattern 42(5-Mosaic)

3

Color temperature adjustment Cool (9300K)

Warm(6500K)

User

4

Writing EDID file

Analog and Digital

5.1.1 Preparation:

1. Setup input timing to any preset mods or patterns.

2. Enter factory mode (press “e-Key” then press “power” button to turn on monitor).

3. Move Black cursor into “BURN IN MODE” tag and select “ON” to enable burn-in mode.

4. Power off the monitor, remove the input source and then power on again.

5. Setup unit and keep it warm up for at least 30 minutes.

5.1.2 Timing adjustment: (Analog only, it is not required for DVI-D input source)

1. Enter factory mode (press “e-Key” then press “power” button to turn on monitor).

2. Select timing mode from table 1 and input full screen display pattern to monitor.

3. Press “Auto-Key” to run “AUTO adjustment” function for geometry adjustment.

4. Clear user area in EEPROM.

5. Check if the position, phase and clock of the image are ok or acceptable to make sure function

and performance are ok.

6. Turn off the monitor power.

7. Turn on the monitor power again to check if monitor’s image settings are ok and with following

settings.

CONTRAST = 50

BRIGHTNESS = 85

COLOR = Warm (default setting)

Summary of Contents for X193HQ Series

Page 18: ... 18 3 9 Packing ...

Page 39: ... 39 5 4 OSD Operation Guide OSD Function Requirements ...

Page 40: ... 40 ...

Page 41: ... 41 ...

Page 42: ... 42 Remark Acer logo must be appeared while power on or suspend ...

Page 52: ... 52 Fig 2 Appearance Description ...

Page 53: ... 53 Appendix 3 Control Board ...

Page 54: ... 54 Appendix 4 Power Board ...

Page 55: ... 55 ...

Page 56: ... 56 Appendix 5 Interface Board ...

Page 57: ... 57 ...

Page 58: ... 58 ...